Injection Molds

Injection molding is a processing method widely used in various industries, whether it is automotive, home appliances, consumer electronics or food and beverage, medical and pharmaceutical products, FMCG, maternal and child products, models and toys, and other industries are a large number of plastic injection molding of structural parts and appearance of parts produced by ABS, PC, PP, PE and other plastic injection molding.

Technologies For Injection Molds

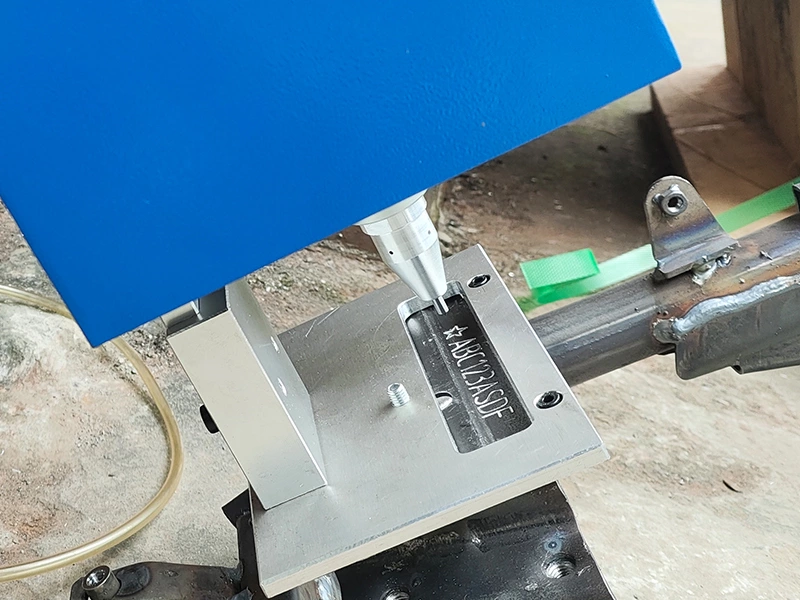

In many large modern injection molding plants, the number of molds and corresponding tools and components is large, even in the hundreds of thousands. In the traditional way, operators usually use cheap and conspicuous water-based markers to write numbers on the different dies of the molds. With the demand of digital production and management, since the beginning of the 21st century, many manufacturers have started to use convenient dot peen marking machines for dot-matrix QR code marking to achieve efficient tracking and management of molds.

- Fast: our high efficiency dot peen and scribe marking machine can mark a standardized 10*12mm QR code in less than 10 seconds;

- Depth: our dot peen and scribe marking machines are achieved 0.3mm depth in one marking pass, and repeatable precisely for deeper;

- Traceability: our dot peen and scribe marking machines are able to mark QR and Data-Matrix code without deformation, easy to scan.

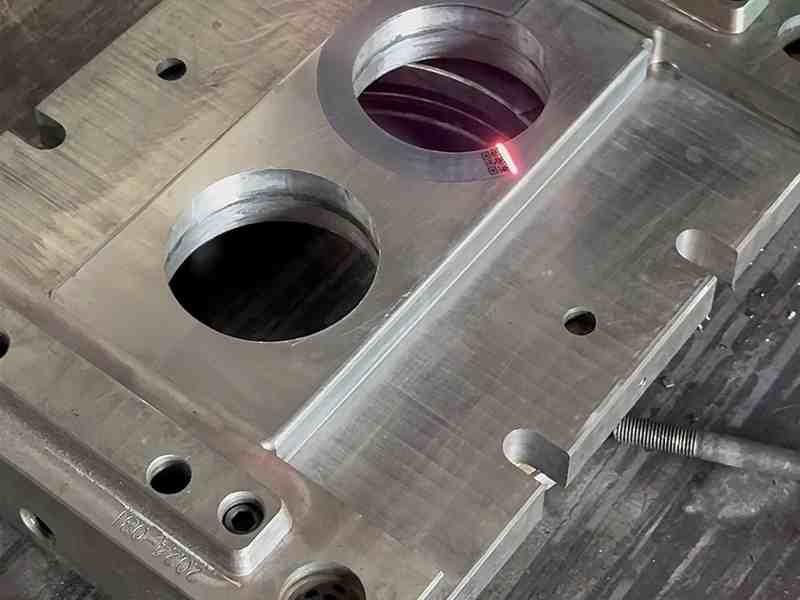

In the mold and die industry, the use of lasers for marking and engraving is more widespread than with dot peen or scribe marking machines. On the one hand, the development of fiber lasers for metal processing matches the development cycle of digital and intelligent production management, and on the other hand, contactless laser marking is more convenient than with conventional dot peen or scribe marking machines and allows for higher marking contrast.

- Easy operation: our laser marking machines are equipped with a red position indicator, especially the small hand-held systems, which are easy to operate by front-line staff;

- Flexibility: our laser marking machines allow flexible engraving on the surface or inside of the mold to achieve three-dimensional graphics or text effects after injection molding;

- Visibility: using MOPA fiber laser annealing or quickly scanned to white after deep engraving, our laser marking machines can generate high-contrast traceability content.

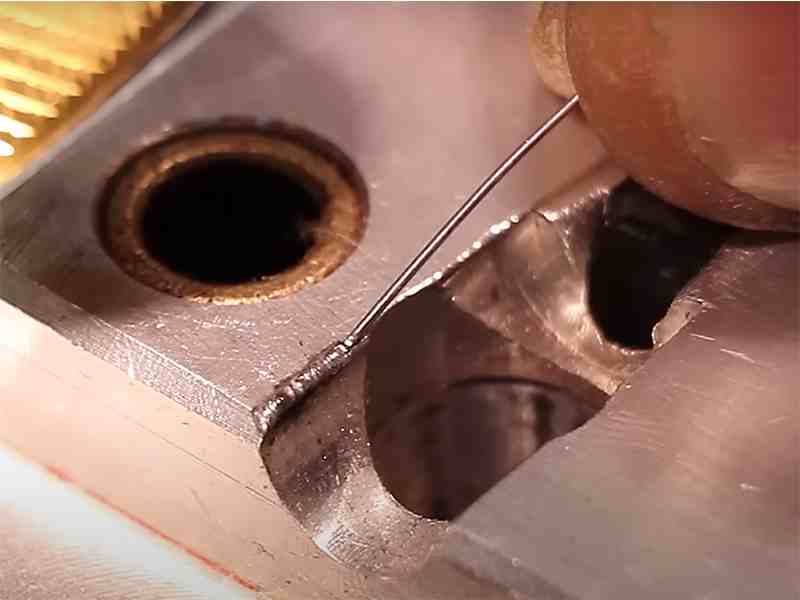

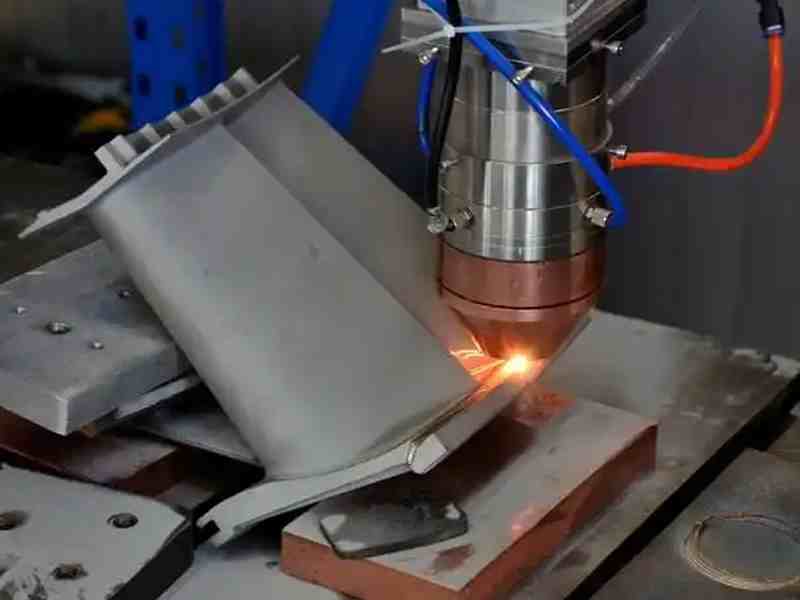

Laser welding is a common method used to maintain and repair injection molds. Molds gradually wear out during injection molding, die casting, and similar processes. Therefore, it is often necessary to fill cracks and gaps in the mold with laser tungsten fusion or other welding materials. This extends the mold’s service life, ensures production yields, and reduces long-term production costs by decreasing the number of replacement molds needed and the number of defective products requiring rework. Compared to TIG welding, the thermal stresses and hot zones of the laser are much smaller, which helps to prevent secondary cracking of the mold.

- Easy to use: our precision YAG laser welding machines for mold and die repair usually equipped CCD microscope to allow the user to visualize the operation.

- Precise: our precision YAG laser welding machines for mold and die repair can reach a minimum line width of 0.01mm and a processing accuracy of ±0.02mm.

- Efficiency: our precision YAG laser welding machines for mold and die repair reached 30 ~ 50 mm/s processing speed, and customizable for faster.

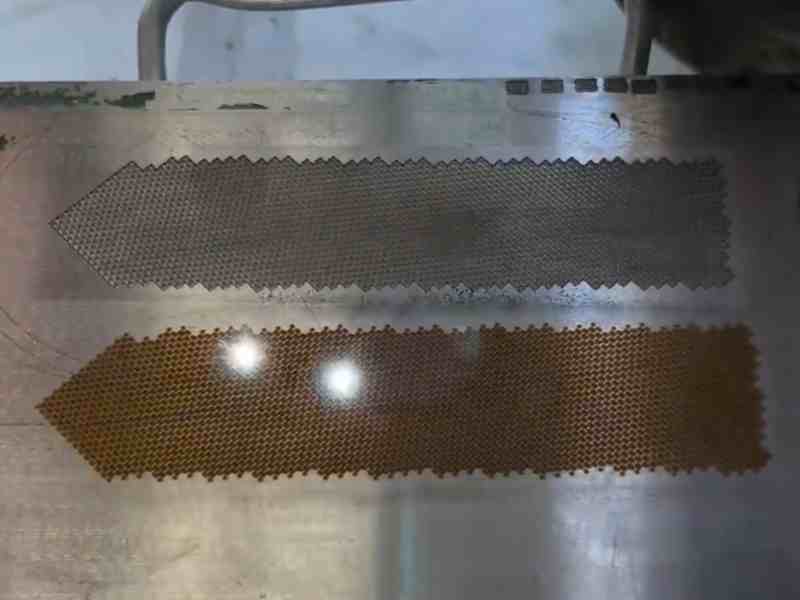

Molds can cause other problems due to residues, affecting normal production. In recent years, with the development of pulsed fiber laser and pulsed laser cleaning machine, laser cleaning of molds has been gradually accepted by professional injection mold manufacturers. The features of non-contact cleaning, no vacuum, no consumables, and non-destructive cleaning of residues through appropriate settings are well received by customers.

- Efficiency: the high-energy laser beam vaporizes contaminants in a very short time with minimal damage to the workpiece.

- Non-consumable: laser cleaning can be operated without detergents or catalysts, a significant savings for high-volume industrial metal derusting.

- Non-contact: laser beam can remove residue on molds at a distance, therefore suitable to clean hard-to-touch area.

Explore Our Machines For Injection Molds

In addition to large-sized matrix such as dies, there are many small and medium-sized parts such as pins, ejectors, etc. In addition, there are tens of thousands of molds in some large-scale injection molding factories, etc. Therefore, the identification of each part of the molds is important for the quick location of the call and the quality of the traceability of the maintenance and other aspects. At present, the mainstream marking method in the mold industry is to use fiber laser for quick marking, its marking contrast is higher than the traditional dot peen marking, in the use of QR code for recording and scanning code reading is very efficient, is the main marking method of digital and intelligent injection molding production.

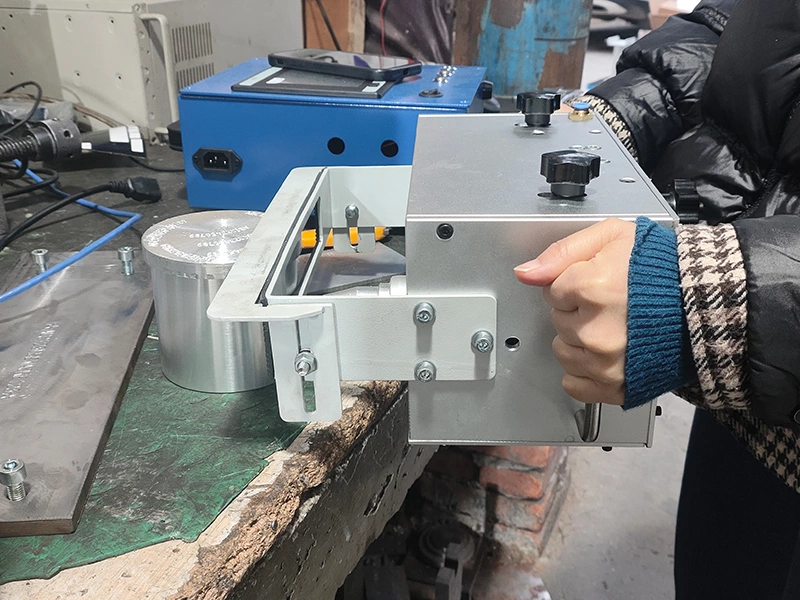

In addition to the use of fiber laser marking, there are some manufacturers are still using the traditional dot peen marking method for quality control of molds, especially the plug-and-play handheld electric dot peen marking machine, can be in the case of molds do not move the rapid editing content and marking, especially suitable for the line of faulty parts such as pins and other faults in the rapid replacement and re-marking, for some users are still For some users it is still an irreplaceable and important piece of production equipment.

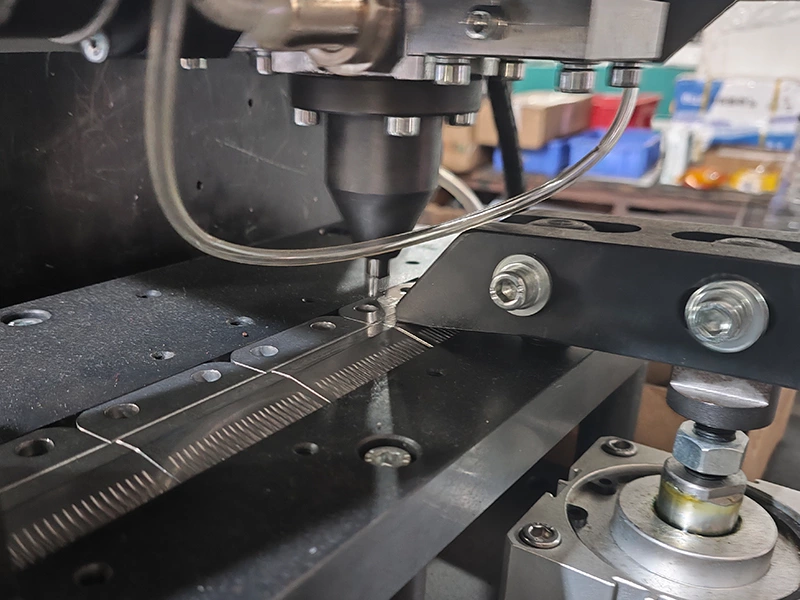

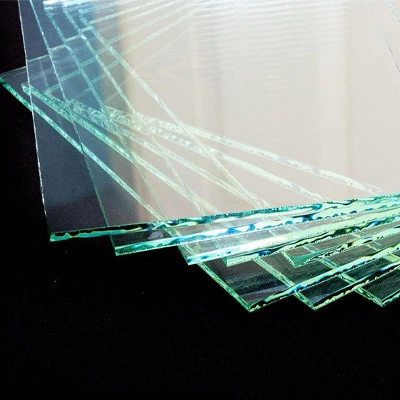

Laser polishing is a new polishing method that replaces traditional manual polishing, and is now usually achieved using high power MOPA laser marking machines, often equipped with a 3D scanning galvanometer using a front-focusing lens to polish the runners. The finish of mold runners is important for the flow properties of plastics and rubbers as well as the appearance of injection molded products. A mirror finish of approximately 8000 mesh can usually be achieved with laser polishing, but higher finishes are still required for the time being.

Many professional injection molding manufacturers use precision YAG laser welding machines for mold repair, which usually have a heavy-duty table and are equipped with a crane arm and CCD microscope, allowing customers to use overhead cranes and other tools to move and maintain the repair molds. In addition, for more obvious or large dents and cracks, can also use a conventional hand-held laser welding machine to quickly melt the wire filler and then use the CNC milling machine and other equipment to re-processing, faster than the use of precision YAG laser repair welding, or even within an hour to re-enter production.

When molding halogen-containing, flame-retardant ABS plastics or HCL-emitting PVC plastics, residues can adhere to mold steel surfaces, which can be difficult to clean with traditional methods such as dry ice, shortening or even halving service life. In addition, when molding rubber or low-temperature plastics with poor flow properties, such as PPSU, which is often used in baby bottles, residues can lead to cosmetic or structural defects in subsequent parts. Regularly cleaning mold runners with a pulsed laser cleaner can extend the life of the mold much better than a mixture of dry ice and chemical cleaners, and greatly reduces the capital consumption of dry ice and chemical cleaners, as well as making cleaning much easier.

Laser cladding is also a new application often used for mold maintenance and repair, in the use of high-power continuous fiber laser scanning mold steel parts laser heat can be deep into the carbon atoms adsorbed to the surface of the mold and the formation of new microstructures, thus restoring the hardness of the mold steel of 90 ~ 95% and extend the service life of a certain amount. In addition, because the laser cladding machine can also be used with multiple wire feed to achieve the effect of stack welding, so for larger size cracks or dents can also provide than mold repair precision YAG laser welding machine or handheld laser welding machine higher repair efficiency. However Due to the often complex shape of mold runners, such laser cladding machines usually require the use of 5-axis or even higher motion control to meet the needs of such applications, and the high cost of high-power fiber lasers, such machines are currently expensive and only used by a few leading injection molding manufacturers, but with its efficiency and cost-effective factors in a long period of time, is expected to be further popularized.

Related Cases

Want an un art handing video demonstration on specialized material? Looking for a solution to your specialized environment or automatic process demand?