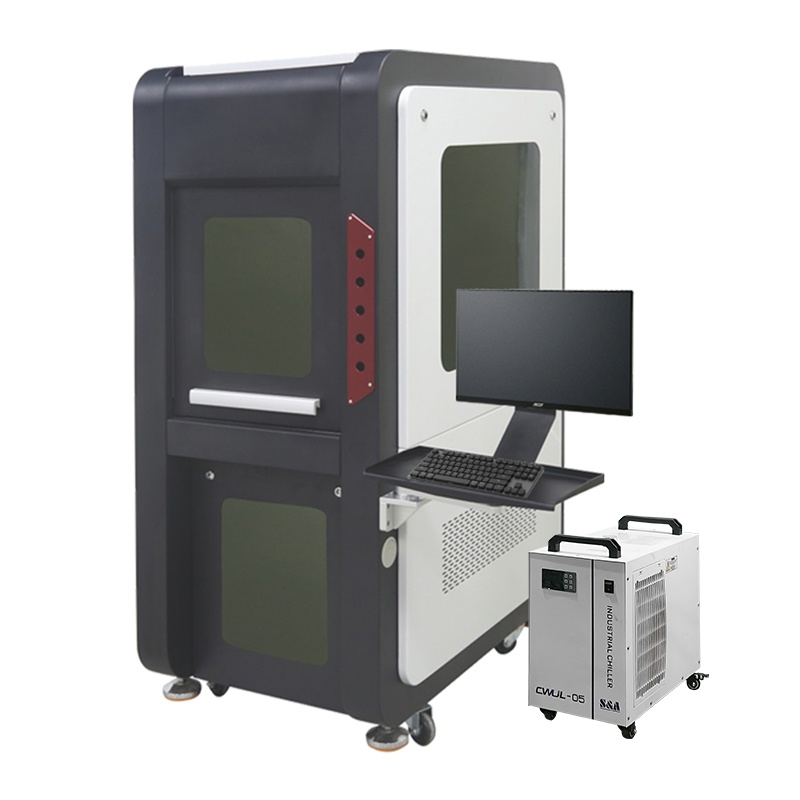

UV Laser Marking Machine

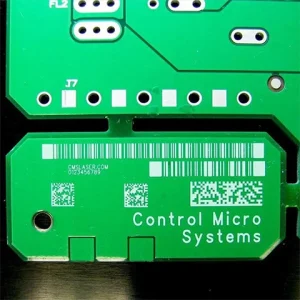

Since 2011, Zixu has expanded from needle markers to laser markers that produce complex, high-contrast, permanent markings on a wide variety of materials and products with minimal damage to surrounding materials, as well as marking logos, manufacturer information, package labels, Unique Device Identifiers (UDI), barcodes, Datamatrix codes (QR), production dates, expiration dates, and more! graphic content on a variety of materials.

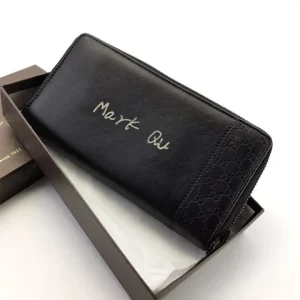

Our reliable UV laser marking machines can be used on virtually all common workpiece materials and are especially suited for non-metallic materials such as plastics, acrylics, glass, ceramic, paper, crystals, diamonds, silicon circuit boards, silicone, wood, paper and textiles, as well as marking metals such as stainless steel, aluminum, copper, gold, silver, chrome, platinum, etc. We can recommend specific configurations and marking parameters based on desired marking or engraving results, speeds, sizes and shapes, and offer a wide range of options from lightly customized rotary marking, 3D engraving or in-line flying systems to highly customized multi-axis systems.

For product pricing, customization, or other inquiries:

Description

In recent years, the price of UV laser markers has dropped, making them the preferred choice for more and more users. Compared to fiber lasers or CO2 lasers, UV laser markers have much less thermal effect when marking or engraving, allowing for higher contrast marking on objects such as plastic bags while reducing scorching or thermal distortion. In addition, UV laser markers typically have a smaller focal point, allowing for sharper lines and smaller graphic content, such as 2mm x 2mm QR codes. In general, we offer standard open or closed tabletop, floor-standing, and in-line UV laser markers. Due to the size and weight of the lasers, we recommend tabletop UV laser markers only for low to medium power applications, such as 3W, 5W, 10W, and for higher power applications, such as 15W, 20W, 25W, 30W, we recommend floor standing or flying UV laser markers only.

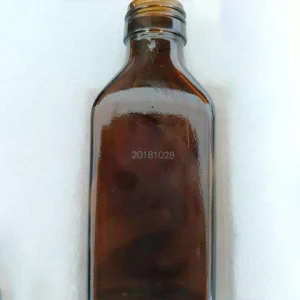

The use of dynamic rotary marking modules with UV laser markers for personalized content marking on products such as glass bottles has been a popular end-market application for us in recent years. Compared to conventional UV laser marking machines, it is possible to mark a continuous 360-degree surface without any splicing, making it particularly suitable for flexible customization for mid- to high-end users. For more complex shapes, such as perfume bottles, a 3D front focus scanning galvanometer can be combined with the UV laser to achieve perfect personalized marking of complex surfaces.

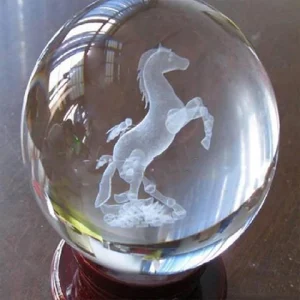

In general, conventional UV marking machines are rarely used for engraving due to their low power and shallow depth of focus. But for materials such as wood and cardboard, the UV laser marking machine’s cutting edge can remain completely undiscolored, which is similar to knife cutting, also used by some customers for flexible production of personalized high-end gift packaging. In addition, combined with the 2.5D post-focusing galvo, 3D pre-focusing galvo, or automatic lifting module, but also achieve deeper engraving depth. In the case of crystal or glass subsurface engraving, as shown in this video, the size of each bubble from the UV marker is smaller than traditional green laser subsurface engraving, allowing for more detailed and smoother 3D graphics.

UV laser marking samples

Technical data of our standardized UV laser marking & engraving machines

Choose from our standard machines below and slide to the right for more information, or contact us for a solution.

Laser Source

| Laser Source Brand | |

| Laser Power | 3W, 5W, 10W, 15W, 20W, 25W, 30W |

| Laser Central Wavelength | 355nm |

| Laser Beam Quality | ≤1.2㎡ |

| Pulse Width | <20ns@60kHz |

| Frequency Range | 40kHz-300kHz |

| Spatial Mode | TEM₀₀ |

| Beam Circularity | >90% |

| Beam Full Divergence Angle | ≤1 mrad |

| Polarization Ratio | >100:1 |

| Polarization Orientation | Horizontal |

| Average Power Stability | RMS≤3%@24hr |

| Pulse-to-Pulse Stability | RMS≤3%@80kHz |

Scanning Galvo

| Scanning Galvo Type | 2D, 2.5, 3D and auto focusing galvo |

| Scanning Galvo Brand | Sino-Galvo, ZBTK, Feeltek, Scanlab or customize |

| Mark Speed | 4000~12000mm/s |

| Positioning Speed | 8000mm/s~23000mm/s |

| Writing Speed | 450cps~600cps |

| Precision and Error | Tracking Error Time ≤ 139~164us Linearity: 99.9% Repeatability (RMS): < 8μRad Gain Error: < 5mRad Zero Offset: < 5mRad Long-term Drift Over 8 Hours: < 0.5mRad Scale Drift: < 40PPM/℃ Zero Drift: < 15μRad/℃ |

F-Theta Lens

| F-Theta Lens Brand | Wavelength OE, JGZOE or customize |

| Scan Area | 70*70mm, 110*110mm, 150*150mm, 175*175mm, 200*200mm, 300*300mm, 350*350mm, 400*400mm, 500*500mm, 600*600mm, 700*700mm, 900*900mm |

Operation

| Operation Software | Thorx-7, Thorx-9, EZCAD, MM3D, LenMark, SCAN, Lightburn, pre-integrated touchscreen software or customize |

| Power Input | 100 ~ 240VAC or 380 ~ 440VAC 3-phases, 50Hz or 60Hz |

| Operation Temperature | 0 ~ 40℃ or 32 ~ 104℉ |

| Relative Humidity | 0 ~ 65% uncondensed |

Material compatibility of our laser type

Review the material you want to mark or engrave. Check out our material application pages for real-world cases.

| Material to mark or engrave | Fiber | MOPA | UV | CO2 |

| Metals | √ | √ | ○ | – |

| Precious Metals | ○ | √ | ○ | – |

| Plastic | ○ | √ | √ | √ |

| Glass | – | ○ | √ | ○ |

| Ceramics | – | – | √ | √ |

| Acrylics | – | ○ | √ | √ |

| Leather | – | – | √ | √ |

| Wood | – | – | √ | √ |

| Stone | – | – | ○ | √ |

| Textile | – | – | √ | √ |

| Paper | – | – | √ | √ |

| Carbon Fiber | – | – | √ | – |

Tips:

√ means the laser type is ideal for marking or engraving these materials;

○ means the laser type will work to mark or engrave these materials, but the requirements are more demanding;

– means the laser type is not recommended for the job.

Clients who chose our uv laser marking and engraving machines.

FAQs about our laser marking machines.

Want an un art handing video demonstration on specialized material? Looking for solution of your specialized environment or automatic process demanding?