Pneumatic Dot Peen Marker

Choose type of your pneumatic dot peen marker

Through years of R&D, Zixu has developed a full range of pneumatic dot peen markers for metal engraving, from standard hand-held model to fully customized for heavy-duty automatic production. First of all, please confirm your application scenario and frequency for a reasonable configuration and quotation.

Why You Might Need a Pneumatic Dot Peen Marking System?

Pneumatic Dot Peen Marking is where we started our business in 2006 and now serve several Fortune 500 companies in the automotive, appearance and electronics industries with remarkable marking effectiveness and excellent value. Our fast and accurate dot peen marking solution enables high-frequency stamping on carbide steel substrates with deep depth and high visibility for OCR scanning at a much lower life-cycle cost than laser systems, including initial purchase and operating costs.

Precision and nimble

Our dot peen markers can engrave dot matrix or continuous lines on curved surfaces and thin tubes without special tuning

High visible traceability

Our dot peen engravers are capable of deep engraving on carbon steel up to 65 HRC with sufficient visibility for OCR scanning

Low life cycle cost

Pneumatic dot peen markers consume needles and compress air, but are still less expensive than lasers

Nimble deployment

Our machines can be hand-held or optionally used with fixtures, modules or a robot for heavy-duty applications

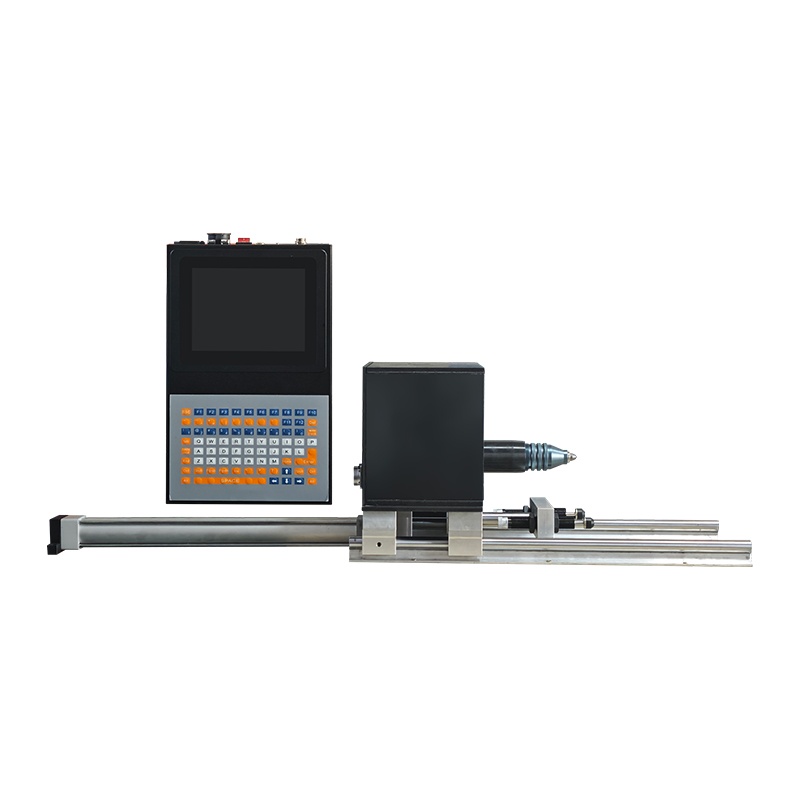

Handheld pneumatic dot peen marking machine

As a handheld pneumatic dot peen marking machine supplier, our hot selling marker, it is widely used in automobile industry for hand marking VIN, chassis and engine number which are too big or heavy to move. It provides smooth marking effect, supports original factory fonts, and easy to operate that one man can finish the marking process from input in minutes. Also, you can customize fixture for complex shape workpiece marking or larger marking area such as pipe, metal nameplate, etc.

Why Choose Handheld Pneumatic Dot Peen Marking over Other Methods?

The preferred choice for completing VIN, chassis number and engine number marking.

Our handheld pneumatic dot peen marking machine can finely complete the task of marking the VIN, chassis number and engine number of almost all automobiles and motorcycles, just enter what you need to mark in the controller for a quick start and finish, meanwhile, we support brand-specific fonts entry to perfectly fit your marking needs.

Accurate and consistent linear VIN marking for regulatory compliance.

VIN, chassis and engine number markings vary from country to country, but our hand-held pneumatic markers can achieve ±0.1mm tolerance in both line depth and width, which is visually perfect and consistent enough to meet the most stringent regulatory standards. In fact, a number of automotive brand representatives have chosen our convenient and superior handheld pneumatic dot peen markers for their re-marking needs.

Incredible value for a remarkably reliable marker.

Our pneumatic markers are proven, and most users get more than five years out of them, and even up to a decade if maintained strictly according to the manual. In addition, we are one of the original marking needle manufacturers in China with competitive price and durability, such as our 93 HRA tungsten steel marking needle series.

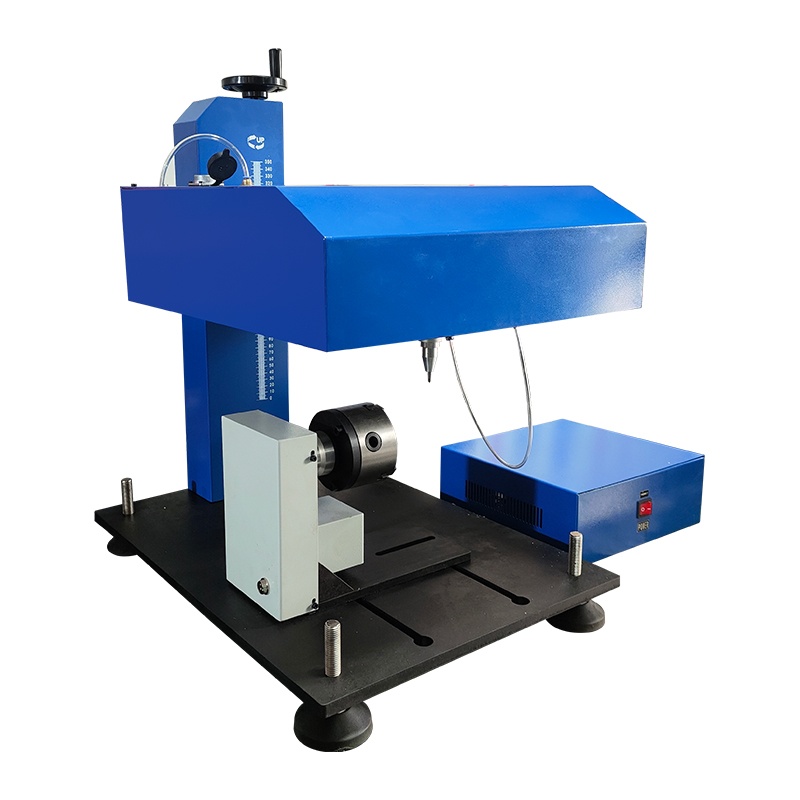

Benchtop pneumatic dot peen marking machine

Benchtop pneumatic dot peen markers are actually more limited to small size workpiece marking; however, it provides higher marking consistency with custom workpiece fixture and able to connect to Manufacturing Execution System (MES) for automatic online coding marking. Therefore, our benchtop systems are widely used to mark metal pipes, flanges, gears, gas bottles, and silver jewelry.

Why Choose Benchtop Pneumatic Dot Peen Marking over Other Methods?

Flexible, consistent, and changeable engraving with our pneumatic dot peen markers.

Our benchtop pneumatic dot peen marking machines can engrave on flat or curved surfaces without additional tuning, but you can swap out clamp fixtures in seconds for different engraving tasks for the best performance and consistency. It also supports an automatic rotary axis for round workpieces and is ready to engrave right out of the box.

Incredible value for a remarkably reliable engraver.

Our pneumatic markers are proven, and most users get more than five years out of them, and even up to a decade if maintained strictly according to the manual. In addition, we are one of the original engraving needle manufacturers in China with competitive price and durability, such as our 93 HRA tungsten steel engraving needle series.

Meet the traceability needs of your most demanding customers.

Demanding customers have always required traceability for quality control of incoming components, especially for metal components where any crack may cause safety issues and damage brand image and customer confidence. Our pneumatic engravers can make permanent marks at 200mm/s and work online with Manufacturing Execution System (MES) for automatic code engraving.

In-line Pneumatic Dot Peen Marking Machine

In recent years, we have encountered several excellent customers with the ability to design and deploy automation. Some are factories that use the equipment, while others are branded or channeled pneumatic marker providers that offer automation solutions. Previously, these customers often chose our standard benchtop pneumatic markers with Thorx-7 systems or purchased heads and controllers separately for flexible automation deployment.

In-line Pneumatic Dot Peen Marking Machine usually need to communicate with MES systems or PLCs. We typically use Thorx-7 or Thorx-9 systems to link these machines with the loading, unloading, and positioning mechanisms on the production line. Since dot peen marking requires physical contact, pneumatic cylinders or motorized guideway modules are often used to move the marking head closer to and farther away from the workpiece to prevent collisions between workpiece and the machine or the marking needles.

Why Choose In-line Pneumatic Dot Peen Marking over Other Methods?

Maximize value by improving efficiency

In general, to implement marking on a fully automated production line, it is necessary to connect to a manufacturing execution system (MES) and a programmable logic controller (PLC). Through instant signal commands, these systems link each movement, positioning, clamping, and other components. This results in high-efficiency, consistent quality marking and reduces waiting and adjustment time, creating more value for customers over the long term.

Experience matters.

Heavier and larger workpieces, such as seamless tubes, bars, gears, flanges, assembled drivelines, hydraulic systems, and engines, are typically marked with handheld dot peen marking machines. However, you can configure a marker to connect to a MES system for automatic coding, a PLC system to control conveyor movement and stopping, or an overhead crane or hydraulic booster arm to reduce operator effort for fast and easy semi-automatic marking.

Lasting and reliable value creation

Automated pneumatic marking improves long-term efficiency and allows for control of position and strength. With movement control of the marking machine, collisions and other accidental factors that could damage the workpiece, personnel, marking machine, or marking needle can be effectively avoided. At the same time, staff can dedicate more time and energy to creative work, providing customers with long-term sustainable development.

Need quality pneumatic dot peen marking machines? We offer the best price!

We have additional discounts for distributors:

1 set or more

5 sets or more

10 sets or more

2 years

Want an un art handing video demonstration on specialized material? Looking for a solution to your specialized environment or automatic process demand?

.jpg)