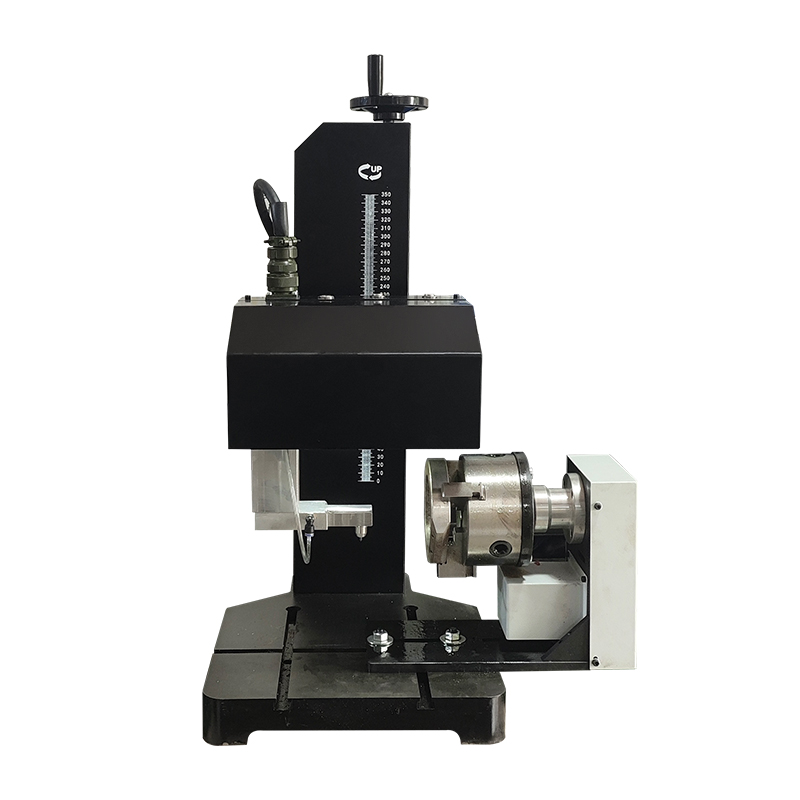

Desktop Flange Marking Machine

After independently developing our pneumatic dot peen marking machine and releasing the first generation in 2009, we gradually received requests from manufacturers of metal connecting parts to mark serial numbers on the outer circumference of flanges of various sizes. Due to the high curvature of the most commonly used flanges of small and medium diameters, we realized that marking horizontally or vertically rotating flanges required controlling the rotary axis and the planetary gearbox via software or PLC on a common desktop pneumatic dot peen marker.

To date, we have a range of desktop flange rotary engravers that support flanges with diameters ranging from 20 to 1000 mm and a weight capacity of one ton per flange. Manufacturers of hydraulic machinery, valves, pinions, and other metal ring parts use this type of equipment to mark the outer surfaces of round key components.

For product pricing, customization, or other inquiries:

Description

Flanges, which are typically made of steel, are widely used to connect tubes and valves. They are used in everything from sophisticated aviation fuel and rocket engines to ordinary water and gas pipes, as well as sewer lines. Due to quality regulations in various countries, flange manufacturers must mark each flange with an individual serial number, batch number, and production date for traceability purposes. Our range of desktop rotary pneumatic dot peen flange marking machines have been developed for this purpose.

Similar to our popular desktop dot peen cylinder rotary markers, our flange rotary markers can be upgraded to deep engraving version. This upgrade is ideal for flanges that require plastic spraying or painting after installation to prevent rusting while ensuring the marking remains visible.

Technical data of our desktop flange marking machines

Choose from our standard machines below and slide to the right for more information, or contact us for a solution.

| Typical Appearance | Machine Type | Scope of Flange Diameter | Scope of Flange Weight | Marking Speed | Marking Depth | Air Supply | Marking Needle |

| Desktop | 10~100mm outer diameter or 80~160 inner diameter or customize | 0.01~10kg or customize | 1~5cps or 5~100mm/s | 0.1~0.3mm for single write on steel, 1mm max or ask for customization. | 0.4~0.6MPa | L4-17-90-M26 or L4-17.2-120-M26 for standard, or custom needles for specialized purpose. |

| Desktop Split | ||||||

| Desktop Compact | ||||||

| Benchtop with inner marking kit |

Choose control software on your flange rotary marking demanding

Our rotary flange engravers come standard with the Thorx-9 controller, which requires input and output (I/O) interfaces; the Kingmark-8 is also available for marking non-English words. If you need more information to make a decision.

Thorx-7 or 9 |  Kingmark-8 | |

| UI Language | English | All language |

| Marking Content | English fonts & dot-fonts, vector graphics, Datamatrix & QR code | All language fonts & dot-fonts, vestor graphics, Datamatrix & QR codes |

| Font Format | SHX, SLF, TTF, SHP | |

| Graphic Format | PLT, SLG, WMF, EMF, DWG, DXF | |

| Controller Configuration | Touchscreen controller or industrial PC controller with USB &RS232 connection | |

| Touchscreen Size | 7’’ | 10.1’’ |

Marking Samples

Clients who chose our flange dot peen marking machines.

FAQs about our flange marking machines

Want an un art handing video demonstration on specialized material? Looking for solution of your specialized environment or automatic process demanding?