Fiber Laser Marking Machine

Since 2011, we have evolved from dot peen markers to laser markers, capable of producing complex, high-contrast, durable marks on a wide range of materials and products with minimal damage to surrounding materials. In addition, we can also mark logos, production information, packaging labels, unique device identifiers (UDI), barcodes, data matrix (QR codes), production dates, expiration dates and other graphic content.

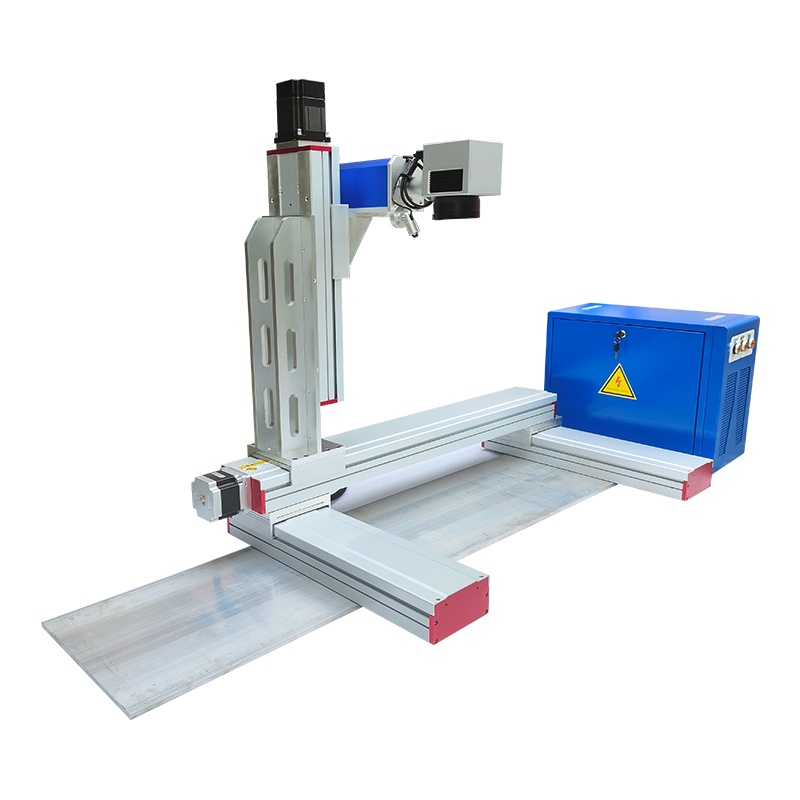

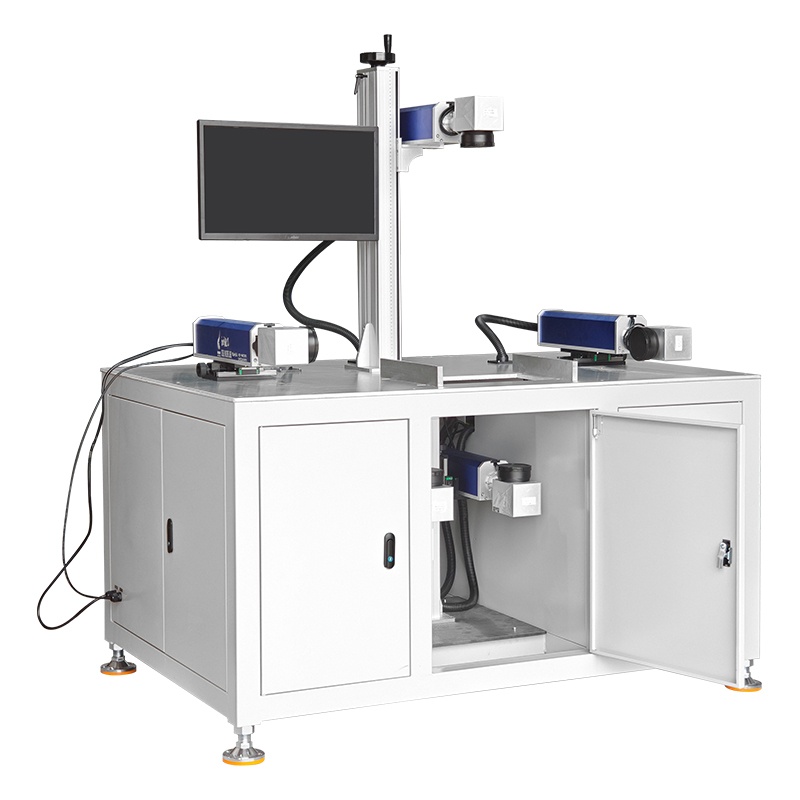

In addition to fiber, fiber MOPA, UV, and CO2 laser marking machines, we offer machine formats such as tabletop, stand-alone, enclosed, flying, and portable machines, as well as large format, autofocus, 3D scanners, vision positioning, multi-axis control systems, and other upgrades to meet the needs of a wide variety of customers marking a wide range of differently shaped material workpieces.

For product pricing, customization, or other inquiries:

Description

Fiber laser is named after the rare earth metal particles doped in the fiber laser beam through the solid-state laser excitation, the structure of the pump laser source life is greatly extended, combined with the fiber’s own anti-jamming and guided, so that the fiber laser marking machine has excellent stability, the typical service life of up to 100,000 hours, far more than any other kind of laser marking machine.

We gained a foothold in China’s automotive and motorcycle manufacturing industries by providing pneumatic dot peen marking machines. As fiber lasers rapidly developed in the 2010s, we began incorporating this type of marking equipment as well. Fiber lasers are ideal for marking identification or quality traceability on small metal or rigid plastic parts because they require no contact and provide a real-time red light preview.

description

In recent years, fiber lasers have become the most widely used type of industrial laser due to their durability and cost advantages. Entry-level 20W, 30W, and 50W industrial-grade fiber laser marking machines dominate the market, while 60W, 100W, and other medium- and high-power lasers are gradually being replaced by MOPA fiber lasers due to the small price difference. For these conventional laser marking machines, we configure different models of fiber lasers from well-known international brands such as Coherent, IPG, MAX, and Raycus according to customers’ needs, in order to provide the most cost-effective laser marking solutions.

Laser Source

| Laser Source Brand | IPG, Raycus, MAX or customize |

| Laser Power | 20W, 30W, 50W, 60W, 70W, 100W |

| Laser Wavelength | 1064 ± 5nm |

| Laser Beam Quality | 1.1 ~ 1.6㎡ |

| Mode of Operation | Pulsed |

| Polarization | Random |

| Single Pulse Energy | ≤ 1mJ |

| Pulse Repetition Rate | 2 ~ 200kHz |

| Pulse Duration | 80 ~ 150ns |

| Output Power Stability | < 5% |

| Output Power Tunability | 5 ~ 100% |

| Duration | ≥ 100,000 working hours for 10% power attenuation |

Scanning Galvo

| Scanning Galvo Type | 2D, 2.5, 3D and auto focusing galvo |

| Scanning Galvo Brand | Sino-Galvo, ZBTK, Feeltek, Scanlab or customize |

| Mark Speed | 4000 ~ 12000mm/s |

| Positioning Speed | 8000 ~ 23000mm/s |

| Writing Speed | 450 ~ 600 cps |

| Precision and Error | Tracking Error Time ≤ 139~164us Linearity: 99.9% Repeatability (RMS): < 8μRad Gain Error: < 5mRad Zero Offset: < 5mRad Long-term Drift Over 8 Hours: < 0.5mRad Scale Drift: < 40PPM/℃ Zero Drift: < 15μRad/℃ |

F-Theta Lens

| F-Theta Lens Brand | Wavelength OE, JGZOE or customize |

| Scan Area | 50*50mm, 70*70mm, 110*110mm, 150*150mm, 175*175, 200*200mm, 220*220mm, 300*300mm, 350*350mm, 400*400mm, 450*450mm, 500*500mm, 600*600mm |

Operation

| Operation Software | Thorx-7, Thorx-9, EZCAD, MM3D, LenMark, SCAN, Lightburn, pre-integrated touchscreen software or customize |

| Power Input | 100 ~ 240VAC or 380 ~ 440VAC 3-phases, 50Hz or 60Hz |

| Operation Temperature | 0 ~ 40℃ or 32 ~ 104℉ |

| Relative Humidity | 0 ~ 65% uncondensed |

MOPA (Master Oscillator Power Amplifier) lasers are made by combining a high-beam-quality, low-power seed laser (master oscillator) with a high-power fiber amplifier, which enables precise control of the laser output and high power amplification. Compared to conventional fiber lasers, MOPA lasers enable pulse width adjustment, a larger frequency adjustment range, and greater power that is easier to achieve.

By adjusting the pulse width and frequency and other parameter settings, you can change the laser absorption efficiency on the surface of different materials, thus realizing a wider range of material adaptation than conventional fiber laser, such as the marking of copper, gold, silver, and other highly reflective metal materials. You can also use off-focus annealing to create pure black, permanent markings on stainless steel, aluminum, and titanium for printing logos or QR codes. At the same time, different parameter settings can be used on stainless steel or titanium alloy surfaces to form different oxide layer structures for color marking.

description

MOPA laser markers can achieve finer control of the laser beam than conventional fiber markers by adjusting the pulse width and frequency, resulting in higher quality markings. In the advanced manufacturing industry, QR or Data Matrix codes are commonly used to identify and trace metal or injection-molded parts. However, achieving the desired marking effect with a conventional fiber laser on such two-dimensional codes is difficult when they are on uneven surfaces or small in size (2×2 mm, 4×4 mm, etc.). This precision allows MOPA laser markers to mark solid black on stainless steel and aluminum surfaces using annealing. They can also create different colored raster structures on stainless steel and titanium surfaces using various combinations of frequencies and pulse widths. Some MOPA lasers, such as the Orion and the JPT M8, can etch, perforate, and cut heat-sensitive materials like glass.

In addition, the structural characteristics of the MOPA fiber laser make it easier to achieve high power than conventional fiber lasers, so it is often used for deep marking or engraving. For instance, our industrial cylinder and valve flange laser rotary marking machines use MOPA fiber lasers with a power output of 100 W or more. Due to the wide range of applications and rapid development of MOPA fiber laser marking machines, we currently offer dozens of lasers from IPG, Coherent, JPT, RAYCUS, MAX, GZTech, Orion, and other brands with power levels of 20W, 30W, 50W, 60W, 80W, 100W, 120W, 200W, 300W, and 500W. We will make the best recommendation according to your needs by object materials and target quality.

Laser Source

| Laser Source Brand | IPG, Coherent, JPT, MAX, Raycus, GZTech or customize |

| Laser Power | 20W, 30W, 50W, 60W, 100W, 120W, 200W, 300W, 500W, 1000W |

| Laser Wavelength | 1064 ± 5nm |

| Laser Beam Quality | 1.1 ~ 1.8㎡ |

| Mode of Operation | Pulsed |

| Polarization | Random |

| Single Pulse Energy | ≤ 4mJ |

| Pulse Repetition Rate | 1 ~ 4000kHz |

| Pulse Duration | 0.5 ~ 500ns |

| Output Power Stability | < 5% |

| Output Power Tunability | 5 ~ 100% |

| Duration | ≥100,000 working hours for 10% power attenuation |

Scanning Galvo

| Scanning Galvo Type | 2D, 2.5, 3D and auto focusing galvo |

| Scanning Galvo Brand | Sino-Galvo, ZBTK, Feeltek, Scanlab or customize |

| Mark Speed | 4000 ~ 12000mm/s |

| Positioning Speed | 8000 ~ 23000mm/s |

| Writing Speed | 450 ~ 600 cps |

| Precision and Error | Tracking Error Time ≤ 139~164us Linearity: 99.9% Repeatability (RMS): < 8μRad Gain Error: < 5mRad Zero Offset: < 5mRad Long-term Drift Over 8 Hours: < 0.5mRad Scale Drift: < 40PPM/℃ Zero Drift: < 15μRad/℃ |

F-Theta Lens

| F-Theta Lens Brand | Wavelength OE, JGZOE or customize |

| Scan Area | 50*50mm, 70*70mm, 110*110mm, 150*150mm, 175*175, 200*200mm, 220*220mm, 300*300mm, 350*350mm, 400*400mm, 450*450mm, 500*500mm, 600*600mm |

Operation

| Operation Software | Thorx-7, Thorx-9, EZCAD, MM3D, LenMark, SCAN, Lightburn, pre-integrated touchscreen software or customize |

| Power Input | 100 ~ 240VAC or 380 ~ 440VAC 3-phases, 50Hz or 60Hz |

| Operation Temperature | 0 ~ 40℃ or 32 ~ 104℉ |

| Relative Humidity | 0 ~ 65% uncondensed |