Valve Marking Solutions – Pneumatic Valve Marking Machine

In different fields, the marking of valves is crucial so as to allow proper identification, traceability, and compliance with regulations. Pneumatic valve marking machines are good examples of engraving devices that mark the surfaces of valves systematically and efficiently. Such machines employ compressed air to actuate a marking pin, which results in accurate and permanent engravings on metals, plastics, among other materials.

What is a Pneumatic Valve Marking Machine?

A pneumatic valve marking machine is a specialized marking device that uses compressed air to actuate a stylus or marking pin, which impacts the surface of a valve to create a permanent and durable engraving. This technology is widely used for marking serial numbers, logos, batch codes, and other essential information on valve surfaces. The engraving process ensures that the markings remain visible and intact even under extreme industrial conditions, including high temperatures, pressure, and corrosion.

Pneumatic valve marking machines are automated or manually operated, allowing users to mark various types and sizes of valves with high precision. They can be integrated into production lines or used as standalone devices, making them versatile for different manufacturing environments.

What are the Advantages of Using a Pneumatic Valve Marking Machine?

Using a pneumatic valve marking machine is a highly popular process for valve marking. This is because of its functionality and several key advantages, making it the preferred choice for industrial applications:

1. Permanent and Durable Markings

The markings generated through the use of a pneumatic marking machine possess enduring resistance to abrasion, oxidation, and harsh environmental factors.

Such durability guarantees that identification markings on products are preserved throughout the entire life cycle of the valve.

2. High Precision and Accuracy

The pneumatic marking system delivers sharp, clear, and precise engravings.

This is crucial for industries where traceability and quality control are essential.

3. Fast and Efficient Marking Process

Compared to traditional engraving methods, pneumatic marking machines offer a higher speed without compromising quality.

They can be used for both batch marking and individual customization.

4. Versatility and Compatibility

Pneumatic valve marking machines can mark a wide range of materials, including stainless steel, aluminum, brass, and plastic.

They can accommodate various valve sizes and shapes, making them ideal for diverse applications.

5. Cost-Effective and Low Maintenance

Pneumatic systems have fewer moving parts, resulting in lower maintenance costs and longer machine lifespan.

They do not require consumables such as inks or labels, reducing operational expenses.

6. Compliance with Industry Standards

Many industries require permanent and legible markings for compliance with safety and quality regulations.

Pneumatic marking machines ensure that the markings meet these stringent standards.

What are the Applications of Pneumatic Valve Marking Machines?

These machines can be used in a variety of industries due to their accuracy, effectiveness, and durability. The most well-known applications are listed below:

- Industries and Manufacturing: Aids in marking products with batch codes, serial numbers, and identification of constituent parts. Aids in quality management processes and supply chain control processes.

- Oil and Gas Industry: Marking systems are employed in conjunction with Valves that are used in refineries, pipelines, or processing plants to mark them with safety labels as well as maintenance records. Helps companies with the sustainable governance of the tracking of valve components to ensure regulatory conformity.

- Automotive and Aerospace Industry: Make sure that marked parts of engines can be easily identified, including hydraulic systems as well as other mechanical components, to ensure the traceability of these crucial sectors.

- Plumbing and Water Systems: Employed to identify valves that are pivotal to water supply infrastructure and irrigation frameworks, plumbing systems, as well as helping system plugins. Improves the efficiency of maintenance for systems by the identification of valve specifications.

- The Power Plants and Energy Sector: Pressure valves are marked along with heat exchangers, as well as parts of turbines to ensure operating boundary alignment.

Custom branding with company logos. The incorporation of company logos into trademark identification enhances the product by proving its usefulness, while the mark increases brand recognition

Two Types of Pneumatic Valve Marking Machines Provided by Zixu

Zixu offers two main types of pneumatic valve marking machines: Horizontal & Vertical Pneumatic Flange/Valve Marking Machine and Handheld Pneumatic Flange/Valve Marking Machine, to meet the operational needs of different customers.

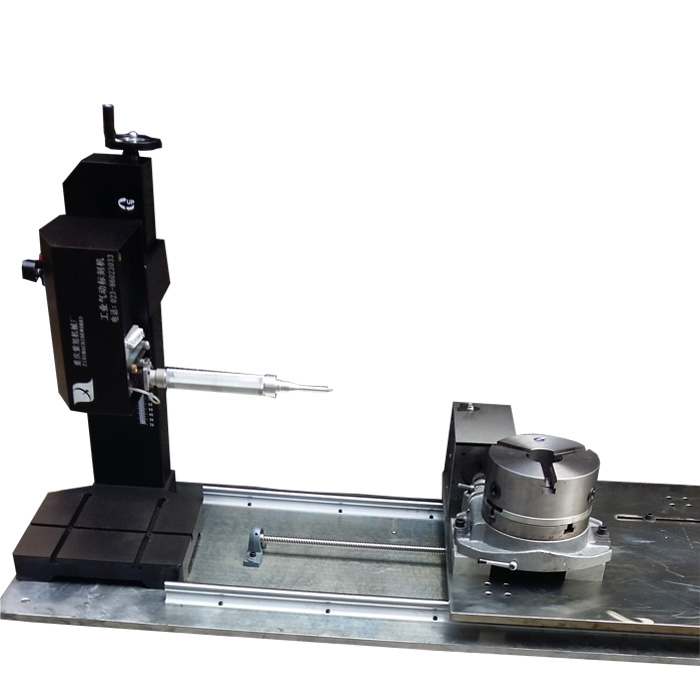

Horizontal & Vertical Pneumatic Flange/Valve Marking Machine

This type of marking machine is designed for both horizontal and vertical valve marking, making it suitable for marking flanges, pipes, and various valve surfaces.

Features:

Zixu flange marking machine is used to mark different types of flanges. Our horizontal & vertical flange marking machine can mark flange with a maximum weight of 250kg! Metal flange marking machine can mark flange maximum diameter of 650mm! Use special long marking peens, which can work well on the flange curved surface.

Handheld Pneumatic Flange/Valve Marking Machine

The model’s handheld marking device can be used for onsite marking where mobility is essential. It provides ease of use when marking large and fixed valves that cannot be moved to a workshop for marking.

Features:

- Easy to carry and work: Lightweight allows effortless movement to different working locations.

- Broader range of operations: Applicable to irregular valves and those fitted in pipes.

- Simple operation: Set up and operate efficiently within markable time frames.

- Durability and accuracy are comparable to stationary models: Every pneumatic marker gives repeatable results in durability and precision regardless their class.

Pneumatic valve markers facilitate industrial marking and traceability as they integrate permanently accurate and inexpensive systems into many industries. Today, these machines are vital in the manufacturing, energy, and pipeline sectors because of advances in marking technology.

With Zixu, the purchase of equipment is accompanied by exceptional features like high efficiency; high durability; flexibility which improves product identification—and therefore compliance with industry standards—and regulatory requirements thereby enhancing business responsiveness.

Recommended Products