Flange Marking Machine: Your Best Solution for Precise Text and Character Marking

In industrial settings such as oil and gas, petrochemical, shipbuilding, and pipeline engineering, flanges play a critical role in connecting pipes, valves, pumps, and other components. However, a flange is more than just a mechanical part—it’s also an information carrier. Regulatory standards and safety protocols require that each flange be clearly marked with key details such as specifications, materials, pressure ratings, and traceability codes.

So, how can you ensure these markings are permanent, accurate, and easy to read? The answer lies in choosing the right flange marking machine. In this article, we’ll walk you through the types of flange markings, common marking methods, and why Zixu flange marking machines are a reliable and efficient solution.

What are the Common Character Marking Contents on Flanges?

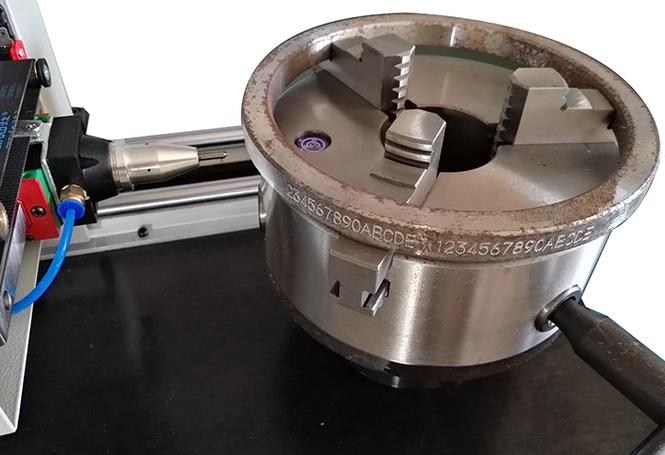

Markings on a flange are essential for identification, traceability, and quality control. These characters are usually engraved on the outer rim or body of the flange and must conform to industry standards. Commonly marked information includes:

- Flange Standard: ANSI, DIN, JIS, GB, etc.

- Nominal Diameter: e.g., DN50, DN100

- Pressure Rating: e.g., PN16, 150LB

- Material Grade: e.g., A105, 304, 316L

- Heat Number or Batch Code

- Manufacturer’s Name or Logo

- Inspection or Certification Marks (CE, API, ISO)

Clear and durable markings ensure that each flange can be traced back through the manufacturing and inspection process, minimizing risk and enhancing accountability.

Comparison of Common Flange Marking Methods

When it comes to marking flanges, several techniques are used in the industry. Each method has its pros and cons depending on production volume, material type, marking content, and budget.

Manual Engraving

Manual engraving involves using a hand-held tool, often a rotary tool with an engraving bit or simply a sharp scribe, to manually carve characters onto the flange surface.

- Pros: Requires minimal initial investment in tools. Offers flexibility in terms of what can be marked (though limited by skill).

- Cons: Extremely slow and labor-intensive, making it impractical for production environments. Mark depth and appearance are highly inconsistent and dependent on the operator’s skill. Characters are often uneven, poorly spaced, and difficult to read. Durability varies based on depth but is often shallow. Cannot easily automate or ensure traceability beyond what is manually written. Not suitable for marking high volumes or complex text/variable data.

Stamping with Molds

This method uses pre-made steel molds or stamps, each with a specific character or symbol. The stamp is placed on the flange surface and struck with a hammer, or the flange and stamp are put into a press.

- Pros: Can create relatively deep and permanent indentations. Simple concept. Low cost per mark if using standard character sets repeatedly.

- Cons: Limited to the available character molds; marking variable data (like serial numbers or heat codes that change frequently) is cumbersome and requires manually selecting and aligning individual stamps. Manual striking results in inconsistent depth and alignment. Using a press improves consistency but lacks flexibility. Requires physical contact and force, which can potentially deform thinner flanges or introduce stress. Cannot easily mark complex logos or 2D codes. The process is relatively slow for applying extensive text.

Dot Peen Marking

Dot peen marking uses a stylus or pin that is rapidly struck against the surface, creating a series of dots that form characters, numbers, and basic graphics. The pin’s movement is controlled by software.

- Pros: Creates durable, permanent marks with adjustable depth, suitable for harsh industrial environments. Can mark on uneven surfaces. Excellent for marking variable data (serial numbers, batch codes, dates) as the content is software-driven. Relatively fast for marking lines of text compared to manual methods.

- Cons: Marks are composed of dots, which might not be as aesthetically pleasing as continuous lines for logos or fine text. Can generate some noise during operation.

Laser Marking

Laser marking uses a focused laser beam to interact with the material surface, creating marks by annealing (color change), etching (surface removal), or ablation (material vaporization). The laser beam’s path is controlled by a scanner head or plotter.

- Pros: Very high speed and precision. Can create fine, detailed characters, complex logos, and high-density 2D codes. Non-contact process, minimizing stress on the material. Highly versatile for marking various materials. Excellent for marking variable data smoothly and quickly. Marks are highly durable depending on the laser-material interaction (etching/ablation creates permanent physical marks).

- Cons: Initial investment is typically higher than dot peen or manual methods. Mark depth can be less than deep dot peen marks unless using a high-power laser for deep engraving applications. Requires safety enclosures due to the laser beam.

Comparing these methods reveals a clear trend: while manual methods are cheap initially, they fail on precision, speed, and consistency for text/character marking. Stamping is better for depth but lacks flexibility for variable data. Dot peen and Laser marking emerge as the modern, high-performance solutions, offering the necessary precision, speed, and flexibility required for comprehensive flange marking.

Types of Zixu Flange Marking Machines

Zixu offers a comprehensive range of flange marking machines designed to address the unique challenges of flange identification across multiple industries. Here are some of the most popular types:

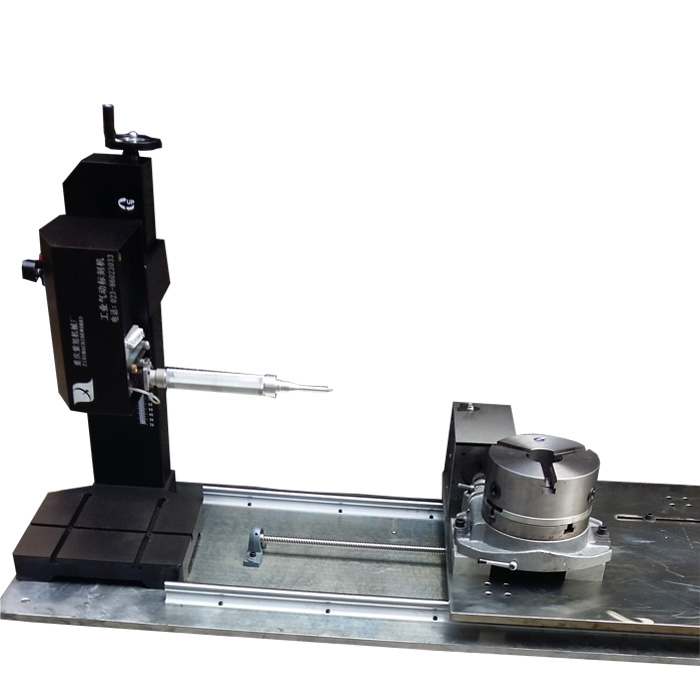

a. Horizontal Flange Marking Machine

Our desktop flange marking machine is specially engineered for enhanced precision and flexibility. We’ve designed a guided track for the marking head, allowing it to move smoothly back and forth, making it easier to adjust the marking distance based on different flange sizes. The rotary fixture offers exceptional stability and secure clamping, ensuring the workpiece remains firmly in place during marking—even under high-impact conditions.

To accommodate complex marking requirements, the marking head features a 360-degree rotating disc, enabling full-angle operation. The marking pin has a long amplitude, making it ideal for marking on curved surfaces, especially flanges. Additionally, the machine includes an extension rod, which allows users to fine-tune the marking position—particularly useful when working with smaller flanges.

b. Handhold pneumatic flange machine

Designed to be compact and lightweight, this portable marking tool is perfect for on-site repair and maintenance tasks. Its ergonomic design ensures comfortable operation and reduces operator fatigue, even during extended use. Built with advanced pneumatic technology and crafted through high-precision machining, it delivers consistent, high-quality marks on various metal surfaces.

Whether working with stainless steel, carbon steel, or other alloy flanges and valves, this machine ensures excellent performance across materials. To ensure workplace safety, it is also equipped with multiple safety features and protective mechanisms, giving operators peace of mind in demanding environments.

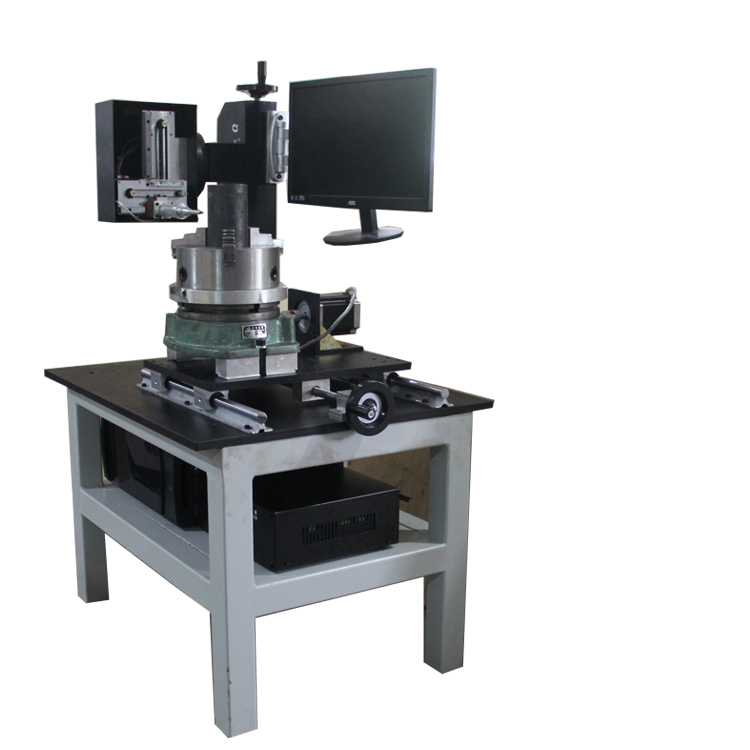

c. Laser Flange Marking Machine

Zixu’s laser marking solutions for flanges typically employ fiber lasers. These systems consist of a laser source, a scanning head with mirrors to direct the beam, and control software. For flange marking, Zixu provides configurations like integrated workstations with safety enclosures or open systems with appropriate safety precautions. Adjustable Z-axis (height) and often rotary attachments are available to accommodate different flange dimensions and mark on the face or potentially the outer diameter. The software allows for highly detailed text, characters, numbers, serials, logos, and 2D codes to be designed and positioned with extreme precision. The laser beam is then rapidly scanned across the flange surface, creating permanent marks through annealing, etching, or ablation.

The non-contact nature is a key advantage, and the speed is exceptionally high for complex character layouts and variable data. Zixu’s software simplifies the process of importing data from databases for automated serializing and marking of variable text elements like heat numbers.

Ready to Upgrade Your Marking Process?

Whether you are producing hundreds of flanges a day or need a reliable solution for on-site marking, Zixu offers tailor-made flange marking machines to meet your needs. Our systems are used by clients in oil & gas, pipeline fabrication, heavy equipment manufacturing, and many more sectors.

Don’t let outdated marking methods slow down your production or compromise your traceability. A flange marking machine from Zixu ensures that every flange leaves your facility clearly marked, fully compliant, and ready for the most demanding applications.

Recommended Products