What is Dot Peen and Scribe Marking?

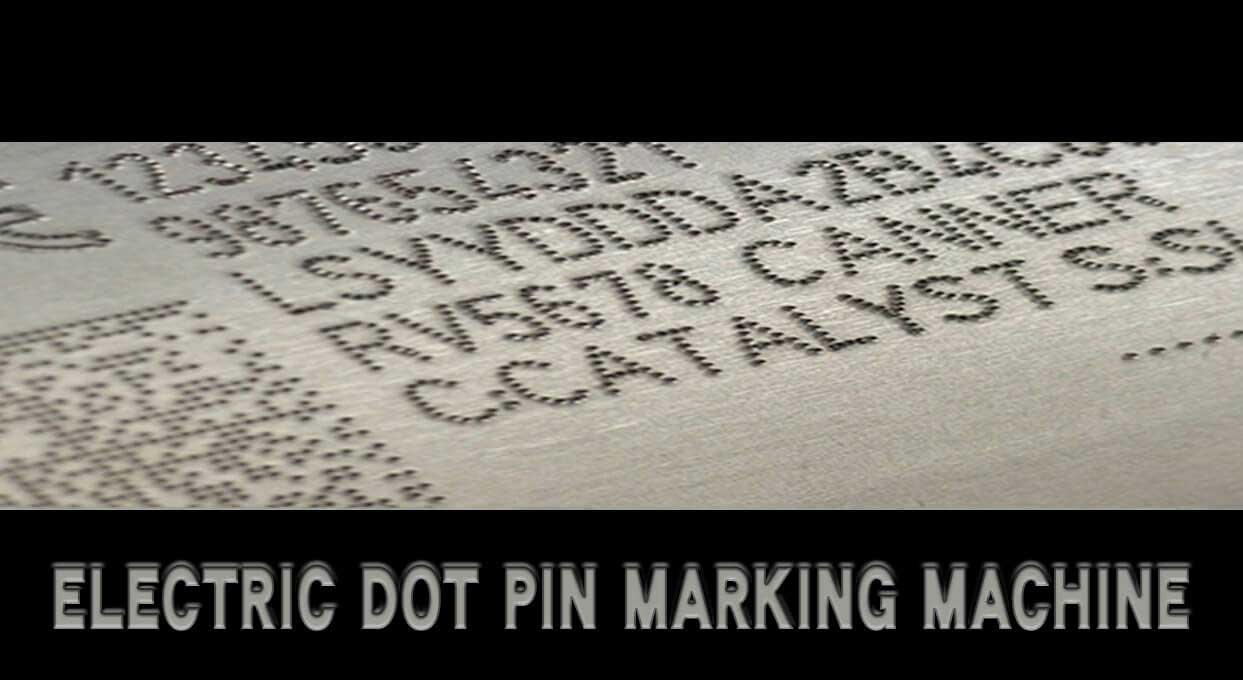

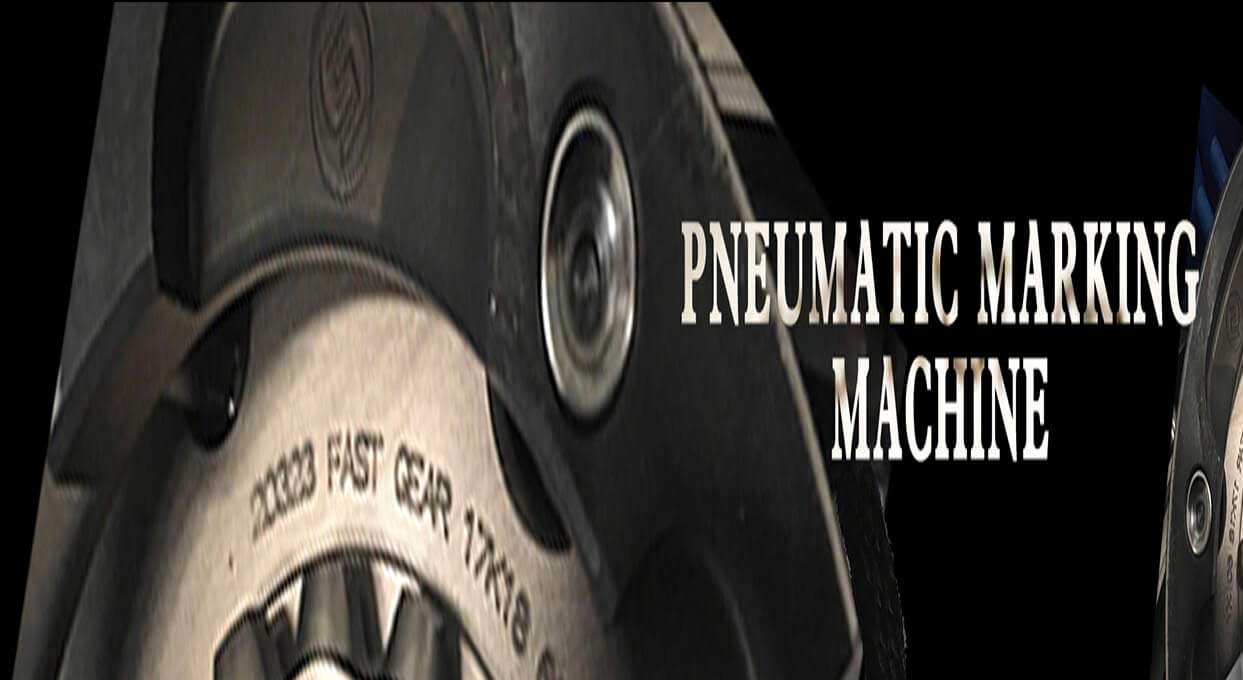

Dot peening and scribing are two relatively long-established mechanical metal marking methods that are widely used for vehicle identification numbers (VIN) and the identification and traceability marking of various types of key industrial components. Traditionally, graphics and numbers are commonly used, but in recent years, the use of data matrix or quick response codes (QR codes) has gradually increased to achieve more content recording and traceability. These two methods leave permanent marks on metal and hard plastic surfaces. The appearance and structure of the machines are very similar, but the principles behind the marking are different.

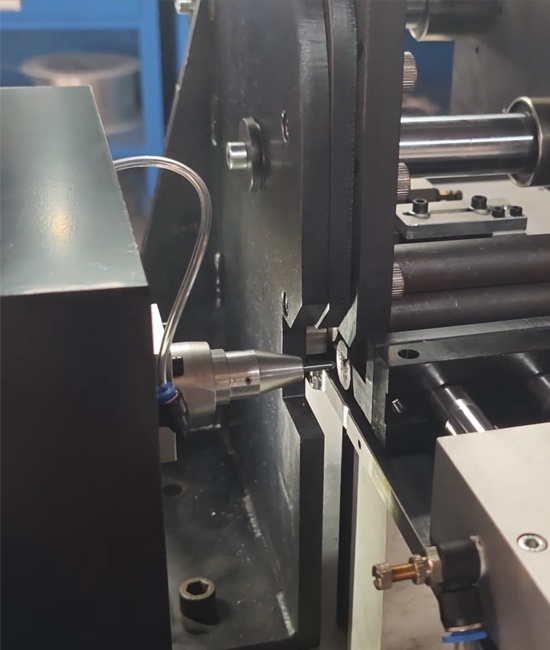

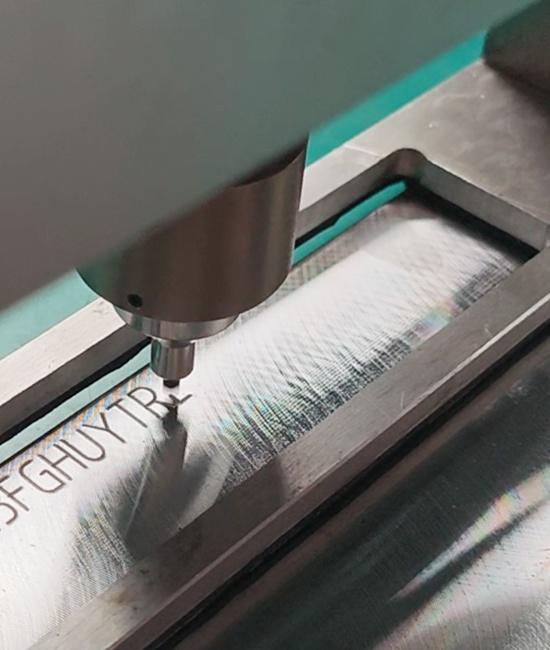

Dot peen marking usually uses compressed air and a throttle valve or solenoid valve to drive the marking needle core to rapidly impact the surface of the workpiece, leaving dots, and relies on a stepper or servo motor to drive the marking needle holder to move on the X-Y guide rails, repeatedly impacting to leave dots or lines, including graphics, letters, numbers, symbols, etc. Therefore, it is also known as Micropercussion, punching, stamping, pin marking, etc., in different countries and industries. Scribe marking uses a throttle valve to control compressed air to press the scribe needle into the surface of the workpiece. Then, the scribe needle holder is moved through the same X-Y guide rail and motor module as dot peen marking to achieve continuous and uniform lines. Dot fonts and graphics can also be marked by controlling the throttle valve.

Select Dot Peen Marking Machine by Principles

Specific Industry Dot Peen Marking Machines

Why You Still Need a Dot Peen Marking Machine in the Laser Era?

In recent years, with the rapid development and price reduction of laser marking machines, particularly fiber laser marking machines, they have been steadily encroaching upon and eroding the traditional market share of dot peen marking machines in the field of permanent identification and traceability marking on metal surfaces. Despite this, dot peen marking machines still possess advantages that laser marking machines cannot yet replace in many aspects, and the unique marking effects of scribe marking machines are currently difficult to directly replicate using laser marking machines. Below, I will analyze the specific performance aspects to explain why dot peen and scribe marking machines remain relevant and popular to this day.

Efficient Deep Marking

Dot peen markers excel at creating permanent, high-contrast engravings with depths of 0.3–0.5 mm on steel surfaces. A typical mark requires only 1–2 strikes, completing the process in under 30 seconds. In comparison, a 300W MOPA fiber laser system can achieve similar speeds but at 5x the cost. Lower-power fiber lasers (30W–50W) struggle with depth consistency—requiring air assist to clear molten debris—and often take 3–5x longer to match the same depth.

Reliability in Harsh Conditions

Fiber laser systems rely on delicate galvanometer scanners with small, precision mirrors vulnerable to misalignment or damage under heavy vibration. While dot peen marking may suffer slight quality degradation (e.g., distorted fonts) in extreme environments, it remains operational where laser systems would fail. The mechanical robustness of dot peen ensures uninterrupted marking in challenging industrial settings.

Lower customization costs

Expanding the working area of a dot peen marking system usually requires only simple modifications, such as extending the guide rails and housing, and involves low costs and delivery times. For laser systems, increasing the spot size by replacing the F-Theta lens reduces the energy density and energy consistency on the focal plane, which may require the use of a higher-power laser, expensive pre-scanning focusing 3D scanning mirrors, or a multi-axis motion control system. These factors make large-scale laser marking extremely complex and costly, with system costs typically increasing by 2 to 10 times.

Maintenance and Serviceability

While fiber lasers are generally reliable, failures in critical components (e.g., laser sources, galvanometers) usually require factory servicing, with costly parts and downtime and rarely will customers purchase and hold these high cost spare parts in stock. Dot peen markers, by contrast, use inexpensive and field-replaceable components. End users can often perform repairs using manuals or instructional videos, maximizing uptime with minimal support.

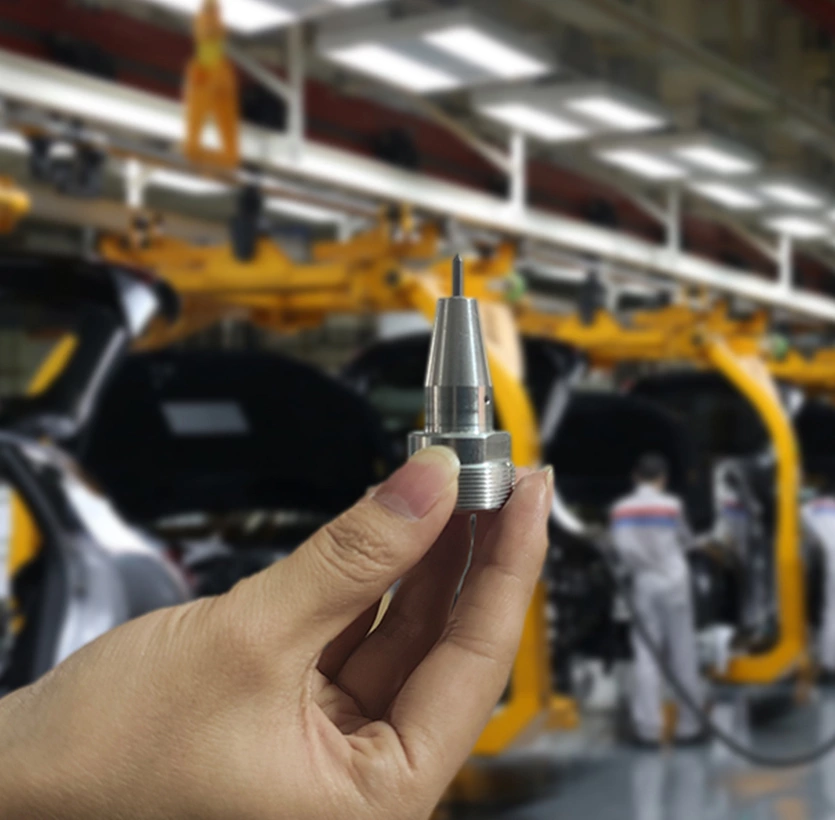

Our handheld pneumatic dot peen marking machine can finely complete the task of marking the VIN, chassis number and engine number of almost all automobiles and motorcycles, just enter what you need to mark in the controller for a quick start and finish, meanwhile, we support brand-specific fonts entry to perfectly fit your marking needs.

How to choose the best dot peen or scribe marking machine for your specific marking needs?

Select by Equipment Type

Handheld markers are the go-to solution for large or fixed components like vehicle VINs and structural steel beams, offering unbeatable flexibility at competitive prices. For precision marking of small hardware components with areas under 10cm, our benchtop systems with custom fixtures deliver perfect results. When dealing with massive industrial parts – like 2-ton flanges, 12 meters seamless steel pipes, or red-hot steel billets – our fully integrated automated marking systems provide seamless production line integration.

Select by Marking Principle

Pneumatic dot peen remains the industry workhorse, creating deep, permanent marks with the most economical consumables – ideal for 24/7 metal part marking operations. Our electric dot peen models offer instant operation (with optional lithium battery packs) for maximum mobility at construction sites and field service applications. For luxury-grade markings, the pneumatic scribe system produces museum-quality engravings – the same technology trusted by Swiss watchmakers for their anti-counterfeit markings.

Select by Marking Area

From compact 40×40mm scribe machines to massive 400×400mm industrial marking systems, we offer the industry’s most comprehensive size range. Custom solutions are surprisingly affordable – simple modifications like extended heavy-duty rails or reinforced enclosures can adapt any system to your specific workpiece dimensions without performance compromises.

Select by Software Features

Select by Software FeaturesChoose from our complete software lineup: Thorx 6 (T6) for basic marking needs, Thorx 7 (T7) and Thorx 9 (T9) for multilingual support, or Kingmark 3 (K3) and Kingmark 8 (K8) for advanced encoding including QR and Datamatrix capabilities. Each controller version is clearly detailed on our product pages, with expert consultation available to match the perfect system to your application requirements.