Chassis Number Marking Machine: Manual vs. Automated Types

In manufacturing industries such as automotive manufacturing this number is used in manufacturing industries like automotive manufacture. It plays an important part in identifying, track as well, and authenticating the vehicles. To ensure that each vehicle is identifiable to the owner and identifiable, a vehicle’s chassis number is marked. It can be utilized to imprint the number on the body of the vehicle’s frame. There are two main kinds of marking machines for chassis numbers, both automated and manual. Each model has distinct features and advantages, which make them ideal for various production needs. Let’s look at the two options.

Common Application of Chassis Number Marking

Chassis number marking(VIN marking)plays a critical role in the automotive industry, serving several important functions. Here are the main applications:

- Vehicle Identification Chassis numbers act as a unique identifier of each vehicle, allowing officials, manufacturers, and owners to trace and differentiate the vehicle from others. It makes sure that each vehicle or truck is recognized as unique.

- Compliance with Regulatory Regulations: Regulatory agencies and governments require that vehicles have an identification number on the chassis to adhere to the legal standards. This is a way to ensure that vehicles are in compliance with the safety, emissions, and environmental standards. It is making registration easier.

- Protection and Security measures: Chassis numbers are integral in stopping vehicle theft and fraud. If the vehicle is stolen, the chassis number acts as a permanent identifier and will be traced back to the legitimate owner, which makes it more than difficult to get stolen cars used for resale.

- Tracking maintenance and warranty: The chassis number can also be utilized to record warranties and service records. It makes sure that the vehicle’s history is properly documented and helps manufacturers as well as service providers to track repairs and replacement of parts.

These functions are vital to ensure transparency, traceability, as well as security throughout the life of a vehicle.

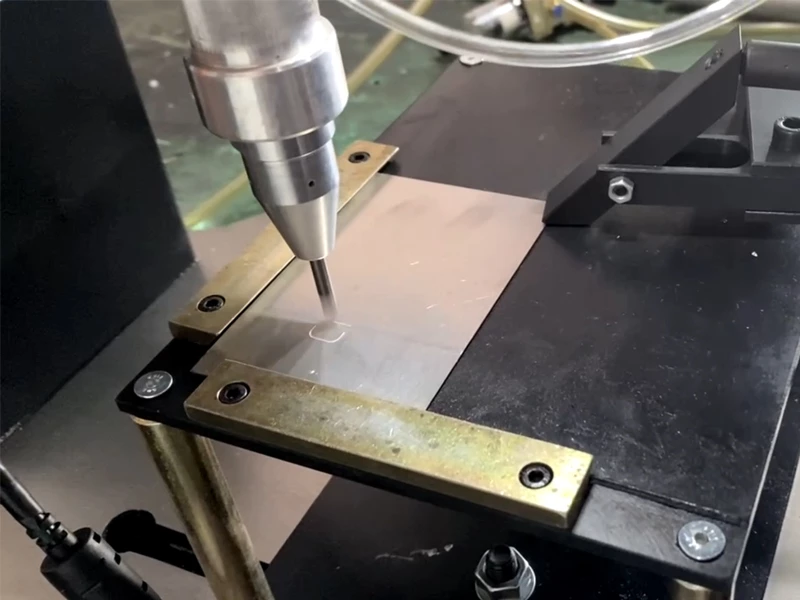

Manual Chassis Number Marking Machines Introduction

The manual chassis number marking machines can be operated manually and are often employed in smaller manufacturing facilities or production lines that are low volume. The machines let operators manually steer the marking tool to write the chassis number on the frame of the vehicle.

- The primary benefit of manual equipment is its cost-effectiveness and requires a smaller initial investment when compared to automated machines, and is a great alternative for small-scale manufacturers or start-ups.

- They also provide flexibility that allows for customization in chassis number formats as well as positioning based on the particular requirements of the vehicle.

- However, manual marking can be labor-intensive that requiring greater time, effort, and energy from the operators, which could slow down the rate of production.

- Furthermore, it is important to note that the accuracy marks are dependent on the skill of the operator and skill, which makes it susceptible to human error and ambiguities.

Therefore, manual marking might not be suitable for large-scale production in which speed and precision are crucial.

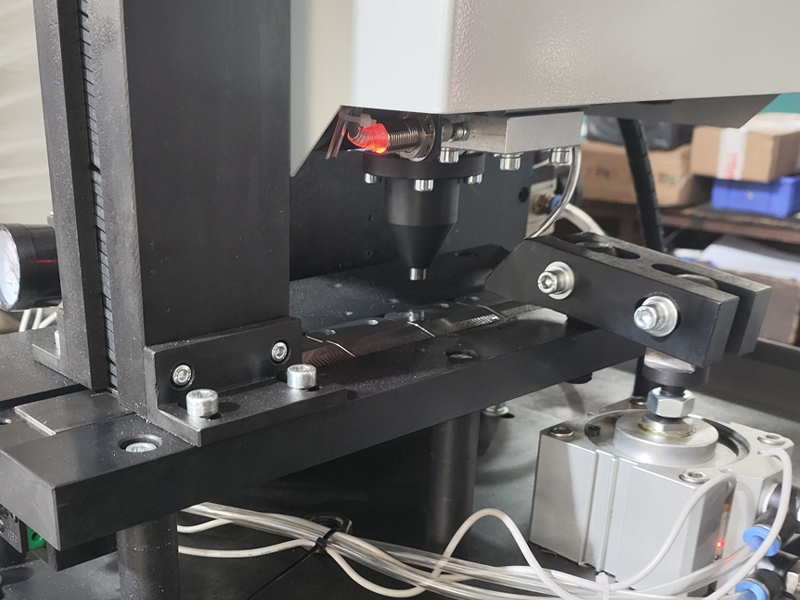

Automated Chassis Number Marking Machines Basics

Automated chassis number marking machines use advanced technology, such as laser engraving or robotic arms, to mark the chassis number with precision and speed. These systems are ideal for high-volume production lines, where consistency and efficiency are crucial. Once set up, automated machines require minimal human intervention, allowing for continuous, hands-free operation.

- The most significant advantages of automated machines are rapid, precise markings that are consistent across large quantities of vehicles. This creates precise lasting markings, which can be hard to alter or modify.

- Automated systems can also lower the chance of human errors, increasing the security of the identification of vehicles. However, they have a greater initial cost and could require special maintenance and repairs.

While automated machines are less flexible than manual systems in terms of customization, they are optimal for manufacturers with large-scale production needs looking to boost output while ensuring accuracy and reducing labor costs.

Manual vs. Automated Chassis Number Marking Machines

When choosing between manual and automated chassis number marking machines, several factors must be considered, including production volume, cost, precision, and flexibility. Below is a comparison to help you decide which option is best for your needs.

| Factor | Manual Chassis Number Marking Machines | Automated Chassis Number Marking Machines |

| Production Volume | Ideal for low-volume or small-scale operations. | Best for high-volume or mass production environments. |

| Cost | Lower upfront cost, more budget-friendly for small businesses. | Higher initial investment, but reduces labor costs in the long run. |

| Accuracy | Dependent on the operator’s skill, can result in inconsistencies. | High precision and consistency with minimal error, ideal for standardized markings. |

| Speed and Efficiency | Slower process due to manual operation, less efficient for large batches. | Fast, continuous operation with high throughput and minimal downtime. |

| Labor Involvement | Requires constant human intervention and manual labor. | Minimal human intervention, reducing labor requirements. |

| Flexibility | Flexible for custom marking styles and small batches. | Less flexible, optimized for high-volume, standardized production. |

| Maintenance | Simple and less costly to maintain. | Requires regular maintenance, can be costly to repair if complex systems break down. |

| Risk of Errors | Higher risk of human error, inconsistent results. | Very low risk of errors, uniform and reliable markings. |

We can draw an assumption:

- Manual Marking Equipment: Ideal for smaller operations that require flexibility and personalization. Manual marking machines have lower costs at first. But, they tend to be slow and are more vulnerable to mistakes, so they are ideal for companies that have lower production levels.

- Automatic Marking MachinesDesigned for production on a large scale, automated machines offer speedier speeds, improved precision, and efficiency. Even though they have an initial cost but they can help cut costs for labor and increase the consistency of production, which makes them ideal for businesses that require high volumes of production.

Choose Which One is Better?

When deciding between manual and automated chassis number marking machines, manufacturers must consider several factors.

- For Low-Volume or Custom Manufacturers: If you have a low production volume or need flexibility to mark different types of vehicles or customizations, a manual marking machine could be a better option. With a lower initial investment, it’s well-suited for smaller businesses or manufacturers on a budget. Manual machines offer greater control over the marking process and can accommodate slight variations in speed or precision, making them ideal for businesses that don’t require high throughput.

- For High-Volume or Mass Production Manufacturers: Automated marking machines are the best fit for large-scale manufacturers or those producing vehicles in high volumes. The speed, consistency, and precision of automated machines significantly improve productivity, making them ideal for environments where quick turnaround times and high accuracy are crucial. Despite the higher initial investment, automated systems reduce long-term labor costs and the risk of human error, making them the optimal solution for manufacturers looking to scale their operations efficiently.

The final decision on automatic and manual machines for marking chassis numbers is based on factors like the production needs, budget, and the precision level you desire. Consider your particular needs and make an informed decision that will enhance the efficiency of your manufacturing processes.

In the end, the manual and automated chassis number marking machines play vital roles in the manufacture of vehicles. It is important to consider your particular requirements, including budget, volume, and flexibility, in order to pick the most suitable option for your needs.

For any need about chassis number marking machines, you can contact our service team.

Recommended Products