Automatic Laser Welder

Whether you are transitioning from conventional MAG or handheld laser welding to automated laser welding to increase productivity, our extensive experience in developing automated welding solutions allows us to provide you with the automated laser welding solution that best meets your needs for precision and automation on a wide range of products, from metal parts to electronic circuits.

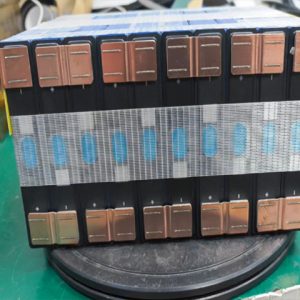

In general, we tend to advise our customers to use automation solutions with a more minimalist appearance and continue to use manual labor in some of the processes to avoid the high product life cycle costs associated with using modules such as robots or CCD visual inspection. On the other hand, for high precision soldering needs such as metal plates, electronic circuits or lithium batteries, automated loading and unloading and fixturing can be customized as needed, as well as features such as CCD visual positioning and visual inspection.

For product pricing, customization, or other inquiries:

Description

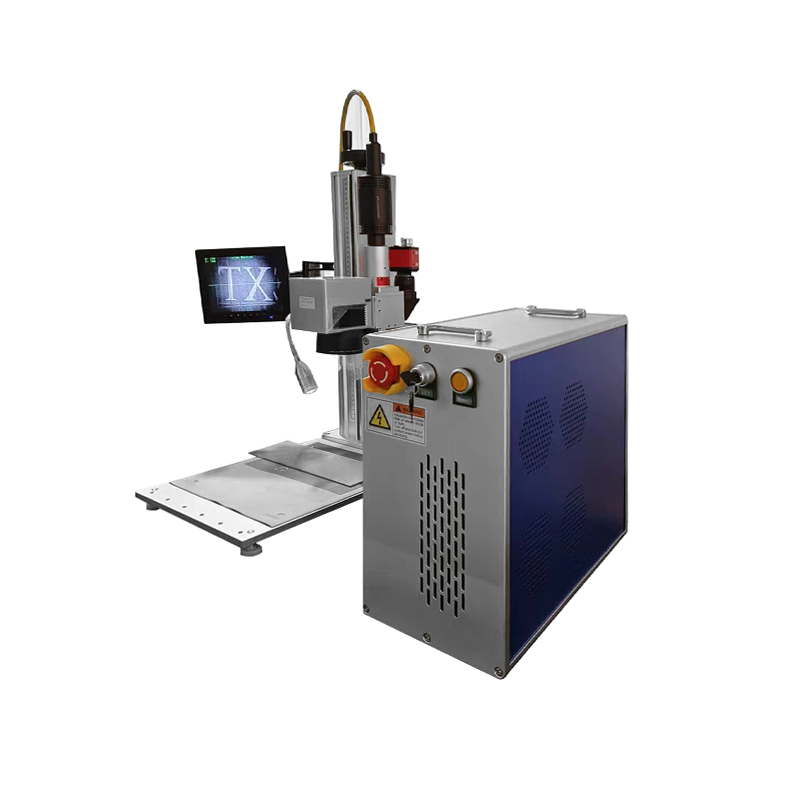

Technical data of our standardized automatic laser welding machines

Choose from our standard machines below and slide to the right for more information, or contact us for a solution.

| Typical Appearance | Machine Type | Welding Type | Laser Brand | Laser Type & Power | Laser Beam Quality | Power Stability | Power per Pulse | Frequency Scope | Pulse Width | Power Supply | Operating Environment | Storage Environment |

| Stand-alone | Laser platform welder | Raycus, MAX, JPT, or ask for customization | CW: 1000W~6000W QCW: 150W/1000W~1000W/6000W MOPA: 100W~1000W | m²<1.6 | ≤5% | CW: N/A QCW: N/A MOPA: 1.5~50mJ | CW: N/A QCW: 1~10KHz MOPA: 1~4000KHz | CW: N/A QCW: 0.01~10ms MOPA: 2~500ns | 100~240VAC, 50~60Hz, or 380VAC | 10~40℃ or 50~104℉, RH10~85% no condensation | -10~60℃ or 14~140℉, RH10~85% no condensation |

| Desktop | Laser galvo welder | ||||||||||

| Stand-alone | Laser galvo welder | ||||||||||

| Robot | Robotic Laser Welder |

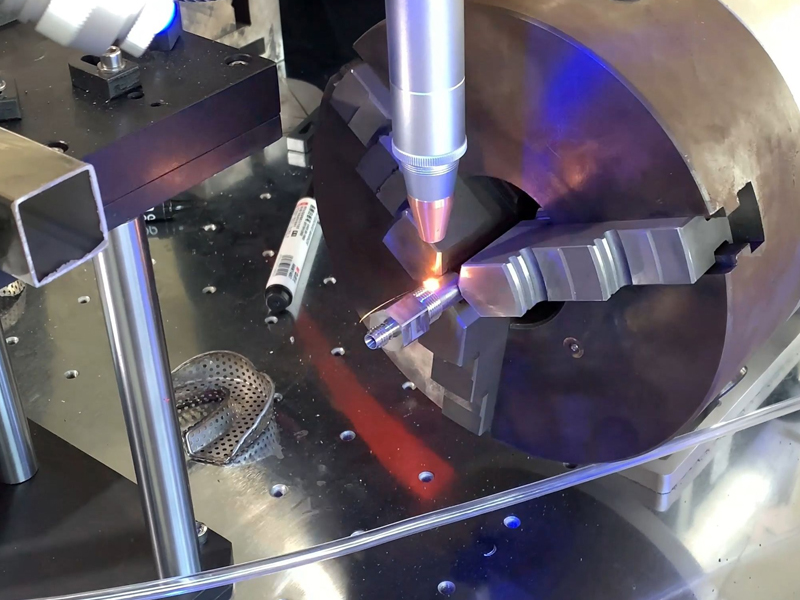

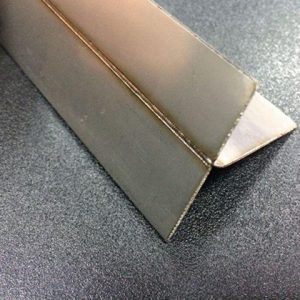

Welding Samples

Clients who chose our Laser Welding Machine.

FAQs about our Laser Welding Machine

Want an un art handing video demonstration on specialized material? Looking for a solution to your specialized environment or automatic process demand?