Pulse Fiber Laser Cleaning Machine

Since 2019, we have been developing and producing our own model of pulsed laser cleaners, and we have seen their gradual popularization from being used only to remove rust and oil from precision injection molds to more applications, such as removing paint from wood for recycling, cleaning oil and graffiti from building facades, removing rust from steel girders and steel cable guardrails on bridges, and so on.

Pulsed laser cleaning offers much higher cleaning quality and efficiency than continuous laser cleaning with minimal damage to the substrate, and can be applied to a wider range of applications than continuous laser cleaning. We offer a wide range of standardized pulsed laser cleaning machines for you to choose from, and for further customized automated cleaning needs, you can contact us for the best configuration and quote.

For product pricing, customization, or other inquiries:

Description

In recent years, due to the price factor, the most common laser cleaners on the market are the 50W, 100W or 200W pulsed laser cleaning machine with 1.5mJ energy per pulse, which are mainly used for precision cleaning of high-value workpieces such as artifacts, molds and engines, and only a few customers who still need the cleaning efficiency will purchase the 200W or 300W models with 5mJ or 15mJ energy per pulse. Today, with the development of lasers and scanning galvo, 300W and 500W air-cooled pulsed laser cleaning machines with 5mJ, 15mJ or 50mJ energy per pulse will gradually replace the previous 50W, 100W and 200W with 1.5mJ, 5mJ or 15mJ models to become the mainstream configuration in the future, while water-cooled pulsed laser cleaners mainstream model will be 500W, 1000W and even 1500W.

By increasing the energy per pulse, the efficiency of oxidation of rust, oil, or paint layers on metals can be increased many times over without changing the cleaning quality. Currently, the 300W air-cooled laser cleaner with 5mJ energy per pulse is our most recommended and cost-effective model, but we also offer air-cooled pulsed laser cleaning machines in 300W and 500W with 15mJ or 50mJ energy per pulse, and up to 1000W average power water-cooled pulsed laser cleaners with up to 100mJ energy per pulse! . With the increased average power and energy per pulse, you also have a wider range of frequency and pulse width adjustments to better balance cleaning efficiency and substrate damage, and even to achieve targeted surface flatness and texture appearance after cleaning.

Technical Data of Zixu Pulse Fiber Laser Cleaning Machines

Choose from our standard machines below and slide to the right for more information, or contact us for a solution

| Typical Appearance | Machine Type | Laser Source Brand | Laser Wavelength | Laser Power | Energy per Pulse | Cooling Method | Cleaning Scope | Cleaning Speed | Air-blowing Galvo | Duration | Operation Environment |

| Standard | JPT, Raycus, MAX or customize | 1064±5nm | 200W/300W/500W | Customize from 1.5mJ, 5mJ or 15mJ | Air cooled | Up to 200mm width, or up to 200*200mm | ≥200m²/s for steel rust, based on type of impurities to being cleaned. | Optional | ≥100000 work hours | 15~35℃ or 59~95℉ Relative humidity ≤80% without condensation |

| Standard | 300W/500W/1000W | Water cooled | ||||||||

| Mini | 200W/300W | Air cooled | ||||||||

| Suitcase | 200W/300W/500W | Air cooled | ||||||||

| Swing Arm | 200W/300W/500W | Air cooled | ||||||||

| Dual Axis Platform | 200W/300W/500W/1000W | Customize | ||||||||

| Enclosed | 200W/300W/500W/1000W | Customize | ||||||||

| Robotic Arm | 200W/300W/500W/1000W | Customize | ||||||||

| Backpack | 100W/200W/300W | Air cooled |

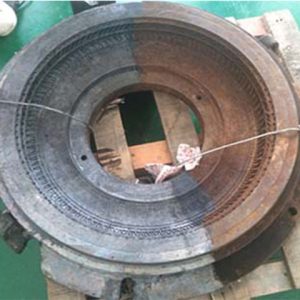

Cleaning Samples

Clients who chose our pulse fiber laser cleaning machines.

FAQs about our pulse fiber laser cleaning machines.

Want an un art handing video demonstration on specialized material? Looking for a solution to your specialized environment or automatic process demand?