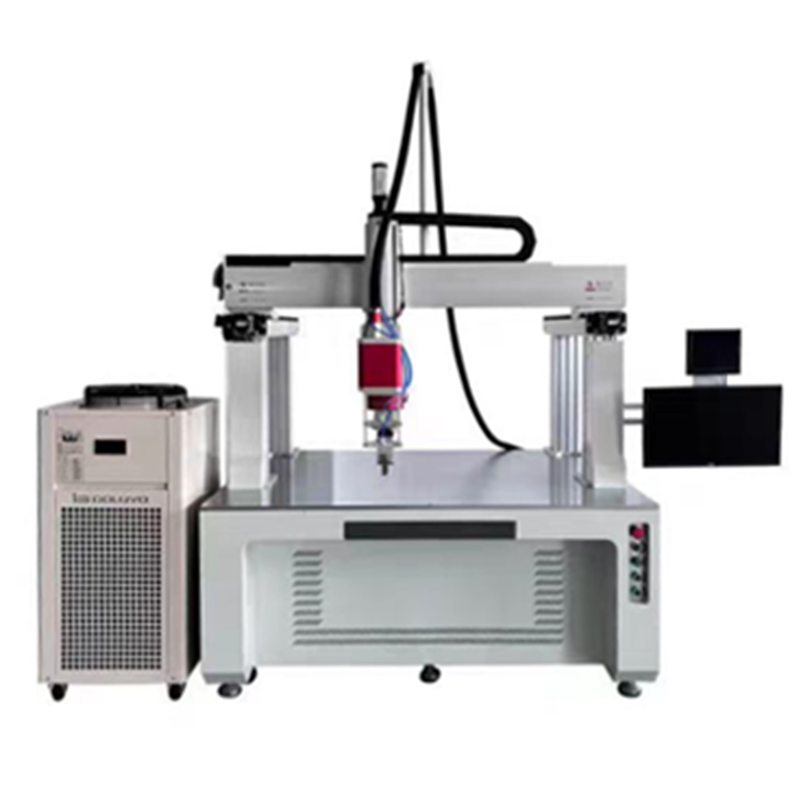

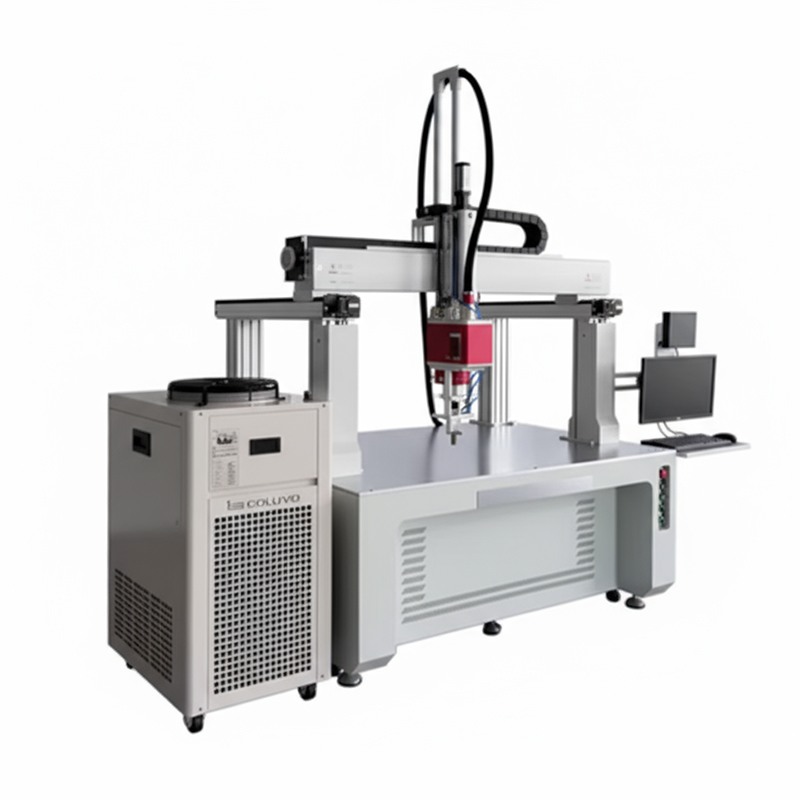

Gantry Automatic Laser Galvo Welding Machine

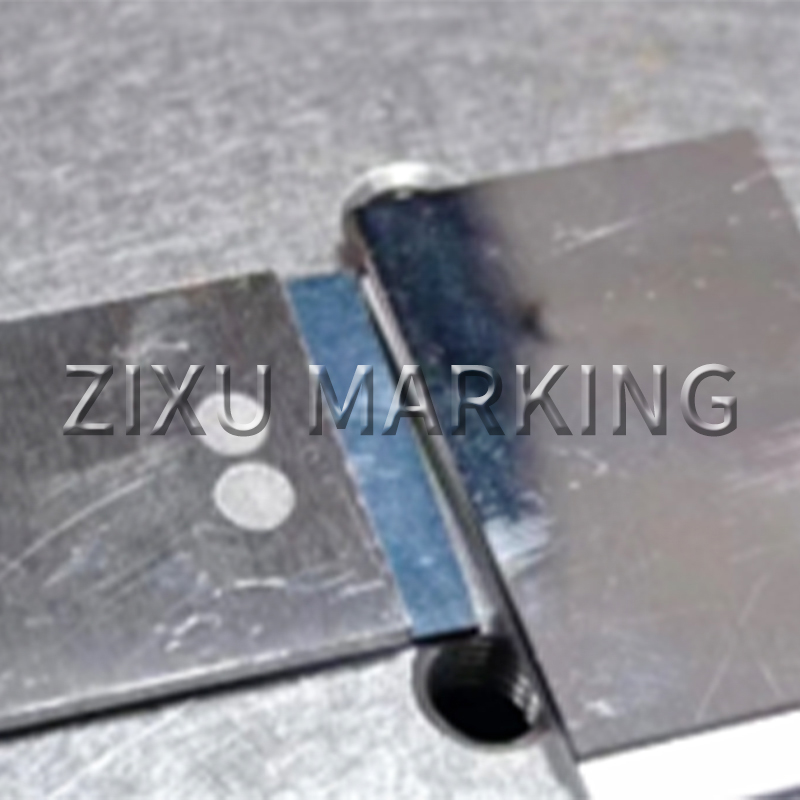

Compared to standard automatic laser welding machine platform, this model utilizes a gantry cabinet to support automated welding of larger workpieces. While the product image shows a commercially available gantry cabinet, customers can customize larger gantry cabinets to accommodate specific workpiece dimensions or integrate the system into existing production lines for automated welding operations. Configuration flexibility accommodates diverse operational requirements, offering choices ranging from cost-effective CW lasers to QCW lasers optimized for welding thin sheets of penetrable materials, and AOB hybrid spot lasers deliver uniform weld quality.

For product pricing, customization, or other inquiries:

Description

| Laser Type | CW Fiber | QCW Fiber | AOB Fiber | ||||||||||||||

| Laser Brand | MAX, Raycus, BWT or customize | MAX, JPT, Raycus or customize | |||||||||||||||

| Laser Power | 1500W | 2000W | 3000W | 6000W | 50W / 500W | 60W / 600W | 75W / 750W | 150W / 1500W | 300W / 3000W | 450W / 4500W | 600W / 6000W | 1500W / 15000W | 1000W / 1000W | 2000W / 2000W | 4000W / 2000W | 4000W / 4000W | 6000W / 6000W |

| Laser Wavelength | 1080 ± 5nm | ||||||||||||||||

| Max. Energy per Pulse | N/A | N/A | N/A | N/A | 5J | 6J | 7.5W | 15J | 30J | 45J | 60J | 150J | N/A | N/A | N/A | N/A | N/A |

| Pulse Duration | N/A | N/A | N/A | N/A | 0.01 ~ 50ms | N/A | N/A | N/A | N/A | N/A | |||||||

| Pulse Frequency | N/A | N/A | N/A | N/A | 1 ~ 10kHz | 1 ~ 5kHz | |||||||||||

| Axis Control | X, Y, Z, Rotary, Tilting | ||||||||||||||||

| Travel Length of Motion | Customize | ||||||||||||||||

| Moving Module Accuracy | ± 0.005mm or customize | ||||||||||||||||

| Wire Diameter | 0.8mm, 1mm, 1.2mm, 1.6mm, 2mm | ||||||||||||||||

| Optional Feeder | Single wire, dual wires, triple wires feeder with mixed feeding. | ||||||||||||||||

| Feeding Speed | 30 ~ 600mm/s | ||||||||||||||||

| Cooling Method | Integrated water cooling | Water cooling | |||||||||||||||

| Air Supply | 0,4MPa compressed air or protective Argon, Nitrogen, etc. | ||||||||||||||||

| Air Blowing Mode | Coaxial blowing, side blowing or mixed blowing. | ||||||||||||||||

| Power Input | 100 ~ 240VAC @ 50 / 60 Hz | 360 ~ 440VAC @ 50 / 60 Hz | 100 ~ 240VAC @ 50 / 60 Hz | 360 ~ 440VAC @ 50 / 60 Hz | 100 ~ 240VAC @ 50 / 60 Hz | 360 ~ 440VAC @ 50 / 60 Hz | |||||||||||

| Operation Temperature: | 10 ~ 40℃ or 50 ~ 104℉ | ||||||||||||||||

| Storage Temperature: | -10 ~ 60℃ or 14 ~ 140℉ | ||||||||||||||||

| Relative Humidity: | 10 ~ 80%, no condensation | ||||||||||||||||

Basic Information

- Unit of measurement: Set

- Retail Price: 1 set or more

- Payment Methods: T/T, D/A, D/P, Other

- Shipping Methods: Ocean, Land, Air, Express, Other

- Shipping Ports: Chongqing, Guangzhou, Shenzhen, Shanghai, Hong Kong

- Place of Origin: China

- Quality/Safety Certifications: CE, FDA

About Company

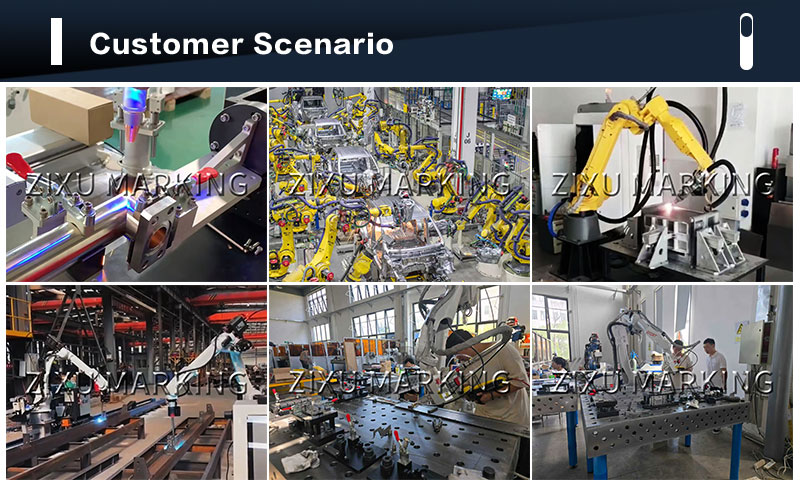

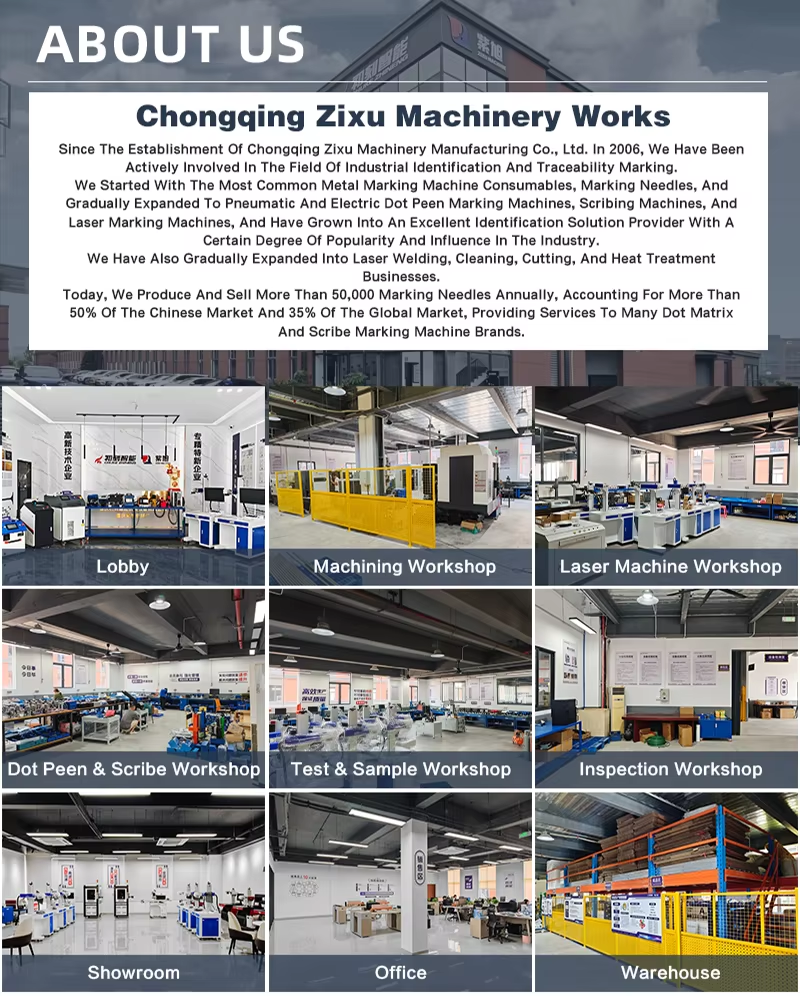

Our company, Chongqing Zixu Machine Works, was founded in 2006 and has been engaged in the marking business. Over the years, we have continued our R&D efforts in marking and provide customized solutions for different work areas and automation levels to maximize our customers’ marking productivity and reduce costs. Contact us for further real customer case and effect.

We have ISO9001, CE, RoHS and other kinds of certificates, and our products are exported to more than 170 countries, such as USA, Russia, UK, France, Germany, Italy, Spain, Switzerland, India, Mexico, Brazil, Colombia, Chile, Slovenia, etc. With more than 15 years of ODM experience in marking machine , we provide excellent marking products and services to our customers. As the source factory of marking solutions, we provide customers with lifetime free training and continuously improve our products to ensure stable profits for our agents. Meanwhile, we are continuously seeking for agents for pneumatic marking machines and laser marking machines.