Why Automatic Laser Welding Machines Are Ideal for Battery Pack Welding?

With the rapid expansion of electric vehicles, portable electronics, and energy storage systems, battery packs have become a crucial component in modern manufacturing. However, assembling these battery packs is not a simple task—particularly when it comes to welding. Traditional welding methods often fall short in terms of precision, speed, and consistency.

Enter the automatic laser welding machine, a cutting-edge solution designed to meet the high demands of battery pack production. As manufacturers search for reliable and efficient ways to boost productivity, many are turning to China automatic laser welding machines for their cost-effectiveness and advanced capabilities. In this article, we explore why these machines are ideal for battery pack welding and how to choose the right one for your production line.

The Critical Challenges of Battery Pack Welding

Battery pack welding poses several unique challenges that can affect performance, safety, and production efficiency:

- Miniaturization: Battery components are often small and tightly packed, requiring highly accurate welding methods.

- Heat Sensitivity: Excessive heat during welding can damage cells or protective circuitry, compromising safety.

- Diverse Materials: Battery tabs and terminals may be made from copper, nickel, or aluminum, each requiring specific welding parameters.

- High Throughput Demand: To meet market demand, battery packs must be produced at scale with minimal downtime.

- Safety Requirements: Poor welds can lead to internal short circuits, thermal runaway, or catastrophic battery failure.

Overcoming these challenges requires a welding method that is both precise and consistent—this is where automatic laser welding machines shine.

Key Advantages of Automatic Laser Welding Machines

High Precision and Consistency

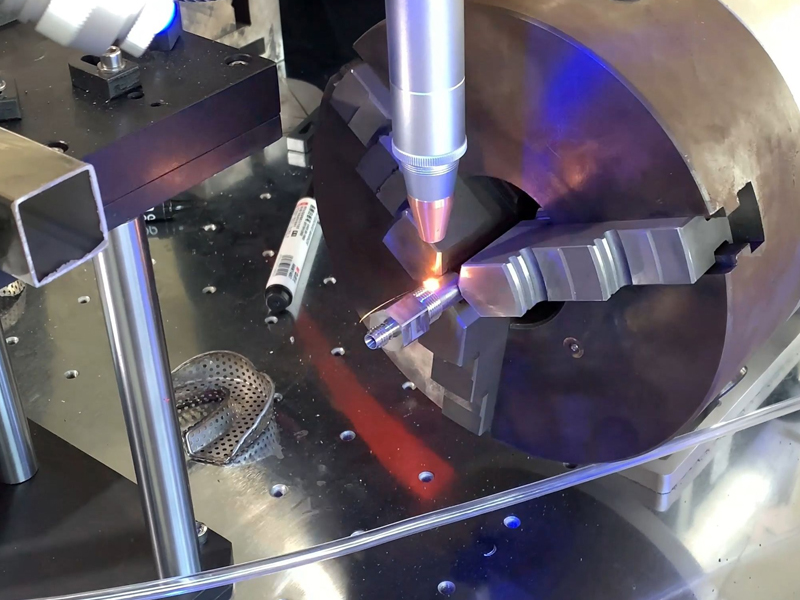

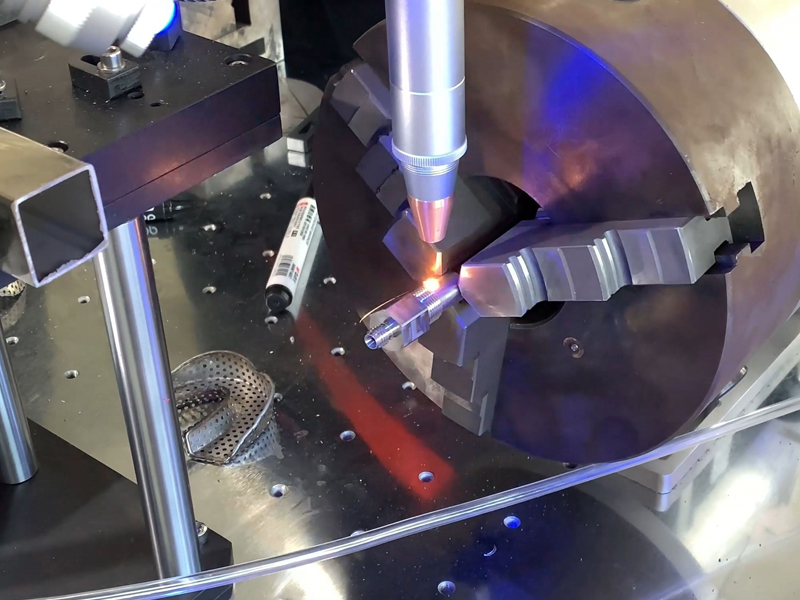

One of the greatest strengths of an automatic laser welding machine is its ability to deliver repeatable, micron-level accuracy. Using focused laser beams and advanced control systems, these machines can perform:

- Micro-welding of small components

- Seam or spot welding with high repeatability

- Consistent weld depth and width without deformation

This is particularly beneficial in battery pack assembly, where precise tab-to-terminal joints are critical for performance and longevity.

Minimal Heat Affected Zone (HAZ)

Battery cells are heat-sensitive, and excessive thermal exposure can lead to:

- Reduced capacity or internal damage

- Weakened structure due to melted insulation

- Safety hazards including fire or explosion

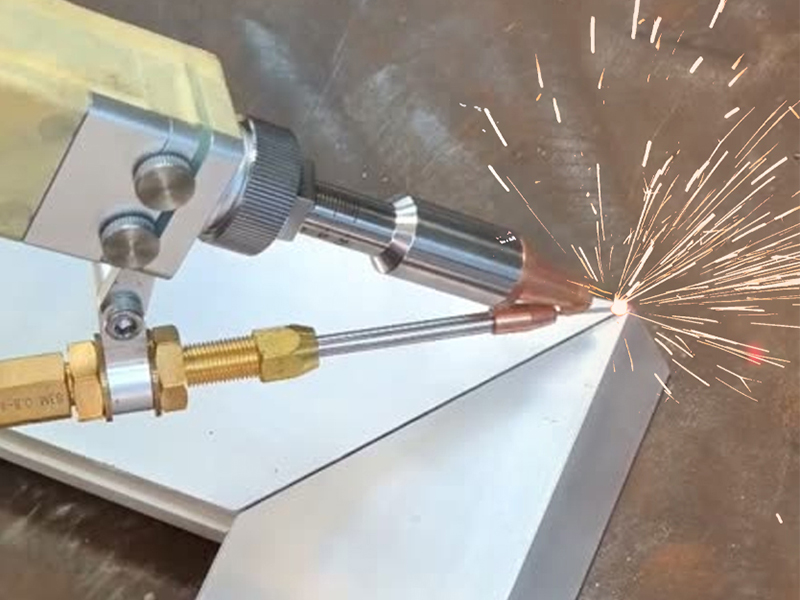

Automatic laser welding machines minimize the heat-affected zone by using concentrated laser energy that fuses metals quickly without heating the surrounding area. This ensures strong, clean welds without compromising battery integrity.

Fast and Efficient for Mass Production

Automatic laser welding is inherently a high-speed process. The laser can move and create welds much faster than traditional welding heads. More importantly, when integrated into an automatic system, the entire welding process can be streamlined for maximum throughput. Modern automatic laser welders come equipped with:

- High-speed galvanometers for rapid beam movement

- Automated feeders and robotic arms for seamless part handling

- Programmable logic controllers (PLCs) for efficient production scheduling

Together, these features drastically reduce welding time, increase throughput, and ensure consistency in large-scale battery pack manufacturing. This is especially important in industries like EVs and power tools where time-to-market is critical.

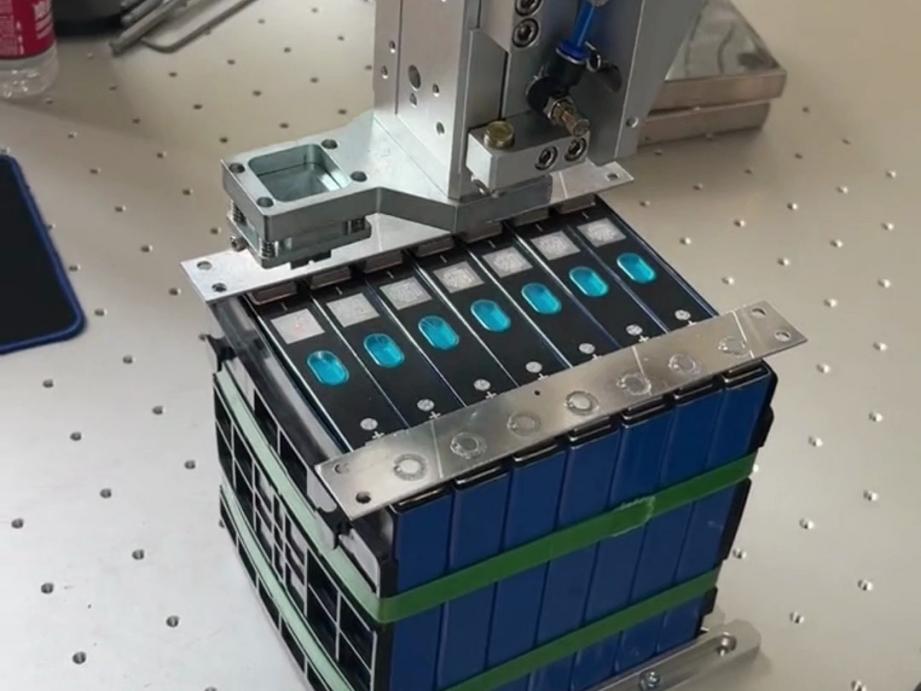

Adaptable to Different Battery Types

Battery packs come in various formats (cylindrical, pouch, prismatic) and utilize different internal and external connection materials. Automatic laser welding machines offer remarkable versatility in handling this diversity. By adjusting parameters such as laser power, pulse duration, pulse shape, focal spot size, and welding speed, the same machine can be configured to weld different materials (like welding copper tabs to aluminum busbars, welding nickel tabs, or joining steel casings) and different thicknesses.

Furthermore, the flexibility of automated systems – whether using multi-axis gantries or robots – allows for easy adaptation to different battery cell geometries and pack designs. Tooling and fixturing can be rapidly changed or adjusted via software, enabling manufacturers to switch between different battery pack models on the same production line with minimal downtime. This adaptability is key for manufacturers producing a range of battery packs for diverse applications.

Reduced Labor Cost and Human Error

The “automatic” in automatic laser welding machine signifies a significant reduction in manual labor required for the welding operation itself. While operators are still needed for setup, monitoring, and maintenance, the actual welding process is performed by the machine. This automation dramatically lowers direct labor costs per welded joint and, more importantly, virtually eliminates human error from the welding process.

Consistency in weld quality is no longer dependent on an operator’s skill or fatigue level. Automated systems follow programmed paths and parameters precisely, leading to highly repeatable and reliable welds. This reduction in human error contributes to lower reject rates, improved overall production quality, and increased yield. Additionally, removing operators from the direct welding process enhances workplace safety, as laser welding is a contained process. The long-term operational savings and quality improvements achieved through automation make automatic laser welding a highly cost-effective solution over the lifecycle of the equipment.

Applications in Battery Pack Welding

Automatic laser welding machines are widely used in:

- Electric vehicle (EV) battery modules

- E-bike and scooter batteries

- Consumer electronics (laptops, smartphones)

- Energy storage systems (home and industrial)

- Power tools and gardening equipment

Each application requires precise control over weld depth, joint strength, and thermal management. Automatic laser welders meet these demands by offering customized solutions for every battery configuration.

How to Choose the Right Machine for Battery Pack Welding

Selecting the appropriate automatic laser welding machine is a critical decision that impacts production efficiency, quality, and cost. Manufacturers should consider several factors:

| Selection Factor | Details & Recommendations |

| Laser Source Type | – Fiber Laser: Best for precision and efficiency; handles copper and aluminum well. |

| – Nd:YAG: Older technology, less efficient, mostly phased out. | |

| Power & Beam Quality | – Recommended power: 200W–1000W for battery applications. |

| – Focus on beam stability and quality over raw power. | |

| Integration Capabilities | – Support for vision systems and robotic arms. |

| – Compatibility with MES/ERP systems for smart manufacturing. | |

| Material Compatibility | – Must handle various metals: nickel, copper, aluminum. |

| – Should support different tab thicknesses and battery structures. | |

| Manufacturer Support | – Look for: After-sales service, training, spare parts, and warranty. |

| – Zixu automatic laser welding machine providers now offer global support. |

Conclusion

The rise of high-performance, safe, and cost-effective battery packs depends on advanced manufacturing. As battery designs grow more complex, automatic laser welding machines stand out by offering the precision, speed, and minimal thermal impact that traditional methods lack.

From cell connections to final pack sealing, laser welding ensures strong, consistent joints with lower labor costs and high adaptability. Investing in the right system is key to scaling battery production safely and efficiently. As demand grows, automatic laser welding will remain a core enabler of next-generation clean energy solutions.

Recommended Products