Pulsed Laser Cleaning Machines: History, Applications, and Trends

For quite some time now, MOPA fiber laser markers have been employed for tasks like meticulous paint removal and surface polishing. Recently, however, the increased availability and market manufacture of MOPA fiber lasers has resulted in a decrease in their price per watt. As a result, the application of pulsed laser cleaning systems is more widespread than it used to be and has evolved into a novel laser-based technology. In this comprehensive report, I will present the principles underlying pulsed laser cleaning, its historical development and technical characteristics, as well as trends related to its implementation. This information is vital in making informed purchasing decisions such that valuable time and resources wouldn’t be wasted on ill-suited products.

History of Pulsed Laser Cleaning Machine

Arthur L. Schawlow, a Nobel Prize laureate, was the first to apply pulsed laser irradiation to ink-printed sheets of paper in 1965. The ink would rapidly vaporize whilst the underlying paper remained intact. Later in 1969, Bedair, S.M., and colleagues were the first to start using Q-switched lasers for oxygen and sulfur removal from the surface of nickel, coining the term “laser cleaning.” This concept was only proposed then. Thereafter, in 1973, Asmus John’s group became pioneers of cultural relic removal with lasers. They restored superb works, including Leonardo da Vinci’s frescoes and various statues.

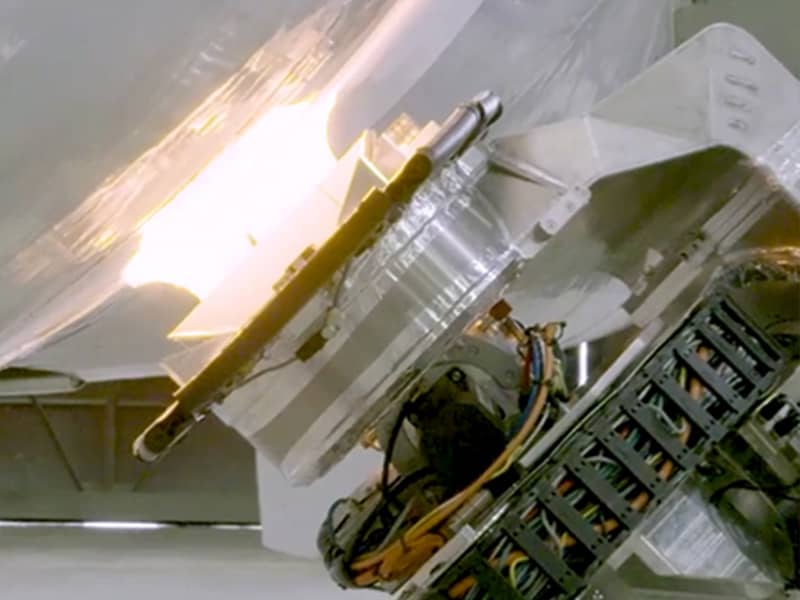

In earlier laboratories of this kind, configurations including pulsed CO₂ laser tubes were quite common; these applied Q-switched techniques to produce laser beams at 9.3, 10.2, and 10.6 μm wavelengths which are very long in comparison to other lasers’ ranges—metals and many other materials don’t absorb these energies easily so matrix metals could be cleaned ultrasonically without damage. Some industrial sectors still employ this technique today, most notably the automotive and aerospace industries: aircraft coating removals use integrating lasers with large-format robots as well as mobile devices capable of performing broad-area cleanings within two days, allowing rapid coating changes for airlines.

Like CO2 lasers, pulsed fiber laser cleaners share the same applications and principles. They stem from MOPA fiber laser marking systems, thus providing an economical solution to high-power cleaning. These devices seem to operate at a wavelength of 1060-1080 nm, which is better absorbed by ferrous material, allowing them to efficiently remove corrosion and oxides from metals. Moreover, 532-nm green and 355-nm ultraviolet laser cleaners incorporate solid-state fiber lasers for frequency multiplication. As these systems are infrequently encountered due to their high costs, they will not be addressed in this article.

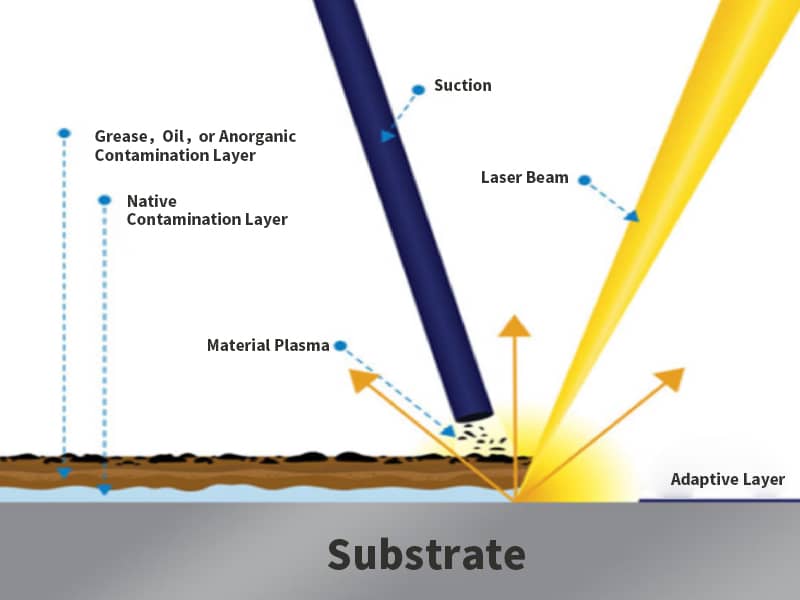

How a Pulsed Laser Cleaning Machine Works

Currently, MOPA fiber lasers are integrated into pulsed laser cleaning systems. These types of lasers have both adjustable pulse frequencies and widths. Operators are able to fine-tune these parameters to make sure that the energy delivered by the laser beam is adequate for surface oxidation, rust, coating, paint, oil residue ablation as well as vaporization without inflicting damage on the substrate.

A derivation of the MOPA fiber laser marking devices, pulsed fiber laser cleaners still maintain an X-Y 2D galvanometric scanning system with F-Theta lens focusing optics at a set working distance for beam focus adaptability, dual-functioning.

As previously stated, pulsed fiber laser cleaners are adaptations based on MOPA fiber laser markers—hence using diode-pumped solid-state lasers (DPSS), power amplification via doped fibers and modulation cavities, X-Y 2D scanning galvanometers for beam steering, and F-Theta lenses providing collimated focus elevation through optics.

Advantages of Pulsed Fiber Laser Cleaning Machines

The following is a list of some of the core factors that have led to the development and application of pulsed fiber laser cleaners in recent years:

- High Cleaning Efficiency: The descaling efficiency for thin rust layers of 25 μm or less is as follows:

- 1.1 m²/h with 100 W and 1.5 mJ of energy per pulse;

- 1.5 m²/h with 200 W and 1.5 mJ of energy per pulse;

- 4m²/h with 200 W and 5 mJ of energy per pulse;

- 7 m²/h with 300 W and 12 mJ of energy per pulse;

Even the most basic efficiency of 100 W is several times higher than that of conventional phosphoric or hydrochloric acid descaling.

- Low Consumption and Maintenance: Fiber laser systems are optically simple, offering excellent longevity and low maintenance. They typically last up to 100,000 hours. Pulsed laser cleaning rarely malfunctions when operated with air blowing correctly. Several systems sold as early as 2017 have not experienced any disruptive failures.

- Contactless Cleaning: This automated approach to cleaning is best suited for narrow, inaccessible spaces. Scanning microscopes can be mounted such that they enable either semi-automatic or fully automatic cleaning processes. Some of our early customers have achieved fully automatic cleaning by mechanically securing the scanner and harnessing the motion of the assembly lines.

- Best Value Systems: A pulsed laser cleaner outputs performed a broad spectrum range considered fabricsworks due to the unidirectional beam provided, which offered better removal results than continuous wave (CW) fiber lasers. It has a lower thermal effect than CO2 lasers while being more efficient at the removal of rust and oxides. Overall, this system is much less expensive than CO2, green, or UV laser cleaning systems.

- Environmentally Friendly and Sustainable Practices: The cleaning processes utilizing pulsed fiber laser technology are eco-friendly since no media or consumables are required, culminating in minimal airborne particle generation, elimination of emissions, and vacuum arm systems that ensure complete isolation from employee work zones in cleanrooms where only properly masked personnel can enter. Furthermore, customers from the pharmaceutical, medical device, and chemical sectors mandate specially designed enclosed workspaces with silicon-sealed device ports for particle extraction to safeguard against contamination into the facility.

What Materials Can Be Cleaned by a Pulsed Fiber Laser Cleaner

- Metals: Substrate metals are the most commonly used for pulsed fiber laser cleaning. Many metal materials, such as steels, aluminums, coppers, brasses, titanium alloys, nickel-based alloys, galvanized metals, and even some advanced metallic materials, have their oxidation and rust layers removed without damage using pulsed fiber laser cleaning.

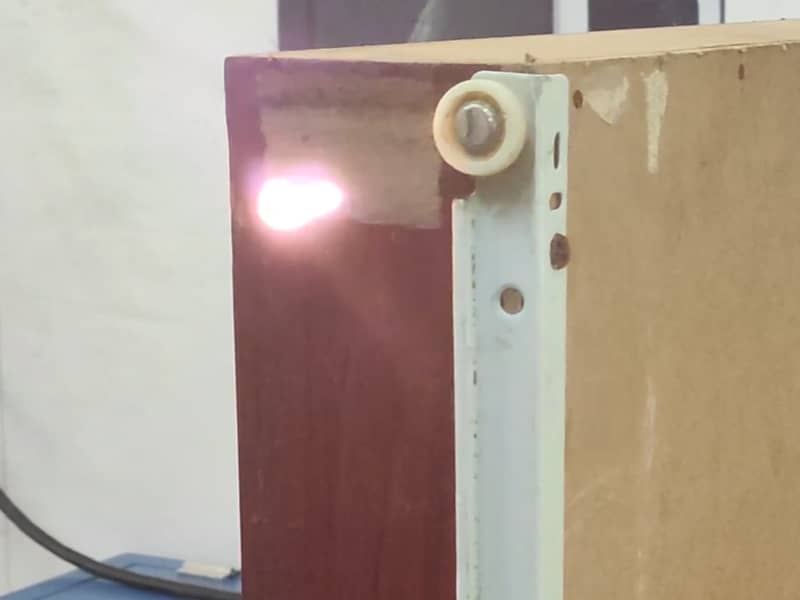

- Oil and Water-Based Paints: Although other contaminants can also be cleared with this technique, it is best suited for the removal of paint and oil coatings. If care is taken to over overheating the substrate (which is normally a steel or iron), removal of oil and lacquers becomes a fast, effortless non non-destructive exercise.

- Plastics and Rubbers: Substrates that can endure high temperatures, like plastics composites, can also be cleaned effectively by pulsed fiber lasers. In order to avoid roughening or melting, which can alter the physical properties like tensile strength, the laser’s pulse width, power frequency have to be finely calibrated. Also flowing coverings from spraying and remnants of plastic or rubber formed through injection or blow molding can be swiftly eliminated by pulsed fiber lasers.

- Silicon Wafers: Silicon wafers are used as the core material for IC manufacturing, and the cleanliness of their surface directly affects the performance and yield of the chip. The pulsed fiber laser cleaning technology can effectively remove tiny particles on the surface of silicon wafers, such as alumina, silicon dioxide, gold, molybdenum, and silicon.

- Glass and ceramics: When appropriate laser cleaning parameters are used, pulsed laser cleaning can effectively remove contaminants from glass and ceramic surfaces without harming the substrate. Although it has become an irreplaceable cleaning method in some industries, it has not yet become widespread, as discussed in the industry section below.

- Stone and Concrete: pulsed fiber laser cleaning removes graffiti, paint, dirt, and other contaminants from stone, concrete, and masonry. Although not as efficient as using high-pressure water jets or traditional chemical cleaners for large areas, this method has become popular because it does not require the use of large quantities of clean water and has no pollutant emissions.

How Industries Deploy Pulsed Laser Cleaning

- Automotive: pulsed fiber laser cleaners are used to clean weld seams, remove oxidation from aluminum frames and engine surfaces on new vehicles, and older vehicles to remove engine carbon deposits, exhaust oil, and old paint for repainting and refurbishing.

- Aerospace: This industry uses pulsed laser cleaning to remove oxides and weld marks from parts, thereby ensuring their overall mechanical strength.

- Electronics and Appliance: Pulsed fiber lasers are now commonly used to clean gallium nitride (GaN) and silicon carbide (SiC) wafers. These wafers are used in electrical parts, optical glass (used in lens sets and displays), and precision ceramic parts, especially in small sizes.

- Railway: Descaling and maintaining railway tracks is essential to railroad transportation. Some railroad operators have installed multiple pulsed fiber laser cleaners on a trolley to efficiently descale tracks while ensuring no area is left untouched.

- Artifact Cleaning: Pulsed fiber lasers have a long history of use for non-destructive cleaning and restoration of wooden and porcelain artifacts. Additionally, the copper statues, doors, windows, knobs, and railings of old buildings can be cleaned and restored.

- Municipal Cleaning: Using pulsed fiber lasers to clean graffiti from building surfaces, metal guardrails in public areas, statues, bridges, and steel cables has become a popular trend that significantly reduces long-term maintenance costs.

Key Points to Consider When Choosing a Pulsed Fiber Laser Cleaner

- Power & Energy Per Pulse: For each sample you submit, we will conduct real-world testing using different combinations of power and energy per pulse to determine the configuration that achieves the optimal balance between cleaning effectiveness, quality control, and cost efficiency.

- Single-or Multi-Mode Laser: In comparison to multi-mode lasers, single-mode lasers appear to possess a lower power and higher beam quality (closer to 1) associated with spatial coherence or focusability of the beam emitted. Single-mode lasers are more likely to cause surface damage, but can be very effective at cleaning surfaces due to their concentrated energy output. Counterintuitively, multimode lasers are preferred because they have increased versatility as they can be operated at higher powers and possess more uniform beam quality, enabling precision cleaning with minimal damage, although these models tend to be more expensive than single-mode alternatives.

- Air-or Water-Cooling: Currently available air-cooled pulsed fiber laser cleaners do meet the needs of most users; however, maintaining an environment under temperature and humidity control is essential for any room housing 500W or less systems. For autonomous unmanned open factory applications operating continuously for 24 hours a day, water-cooled systems outperform other models in terms of stability when excessive automated cleaning is performed due to heavy-duty operational demands mounted on them, e.g., those equipped with water-cooled scanning mirrors.

Should you need assistance identifying an optimal solution or strategic provider-partner for long-term collaborations on laser-cleaning applications, do not hesitate to reach out to us directly.

Recommended Products