High-Precision Pneumatic Engraving Solution for VIN Codes

The non-stop march of industrial technology keeps raising the bar on how firms label goods and track their journeys through the production chain. Inside an automotive plant, the Vehicle Identification Number-VIN for short-gives every car its solo passport number, a detail that never leaves the papers for registration, maintenance, insurance, or recall campaigns. Given the need for a quick, permanent ID, many factories now run pneumatic marking rigs that stamp the VIN in metal, making the code readable long after the assembly line has moved on.

This article will delve into the significance of VIN codes, explore the principles of pneumatic engraving for VIN marking, and discuss the advantages and considerations for selecting and using pneumatic VIN code marking machines.

What is a Vehicle Identification Number (VIN)?

A Vehicle Identification Number (VIN) is a unique 17-character alphanumeric code assigned to every vehicle. Often referred to as a vehicle’s “identity card”, the VIN provides a permanent and unique identifier for each vehicle. Composed of a World Manufacturer Identifier (WMI), Vehicle Description Section (VDS), and Vehicle Identification Section (VIS), the VIN encodes a wealth of information about the vehicle, including its country of origin, manufacturer, year of production, production sequence, and assembly plant. This unique combination of characters ensures that no two vehicles share the same VIN, even over a 30-year production span.

Applications of VINs

The VIN is used for a variety of purposes, including:

- Vehicle identification: It uniquely identifies each vehicle, preventing duplication and errors.

- Vehicle tracking: VINs are used to track a vehicle’s production, distribution, and ownership history.

- Safety recalls: Manufacturers can use VINs to identify vehicles that require safety recalls.

- Insurance and theft recovery: Law enforcement agencies rely on VINs to recover stolen vehicles, and insurance companies use them for underwriting and claims processing.

Common Locations of VINs

VINs are typically located in several places on a vehicle to ensure redundancy and prevent damage. Common locations include:

- Dashboard: On the driver’s side, often visible through the windshield.

- Door jamb: On the driver’s side door, near the latch.

- Engine compartment: On a metal plate or component within the engine bay.

- Vehicle certification label: A sticker affixed to the vehicle, usually on the driver’s side door jamb.

Quality Criteria for Vehicle VIN Marking

Vehicle identification numbers must be inscribed with sufficient quality to guarantee ongoing visibility and survival over the vehicle’s working life. Major benchmarks are as follows.

Legibility: Every character needs to stand out as crisp and unambiguous under direct light and casual inspection.

Permanence: The marking must shrug off solvents, salt, wide thermal swings, and everyday abrasion without fading or peeling.

Accuracy: The original vehicle-identification sequence has to be copied exactly; even a single misfigured digit can defeat the purpose of the code.

Compliance: All stamping and etching processes must comply with the relevant federal, state, and industry rules currently in force.

How Pneumatic Engraving Works for VIN Codes?

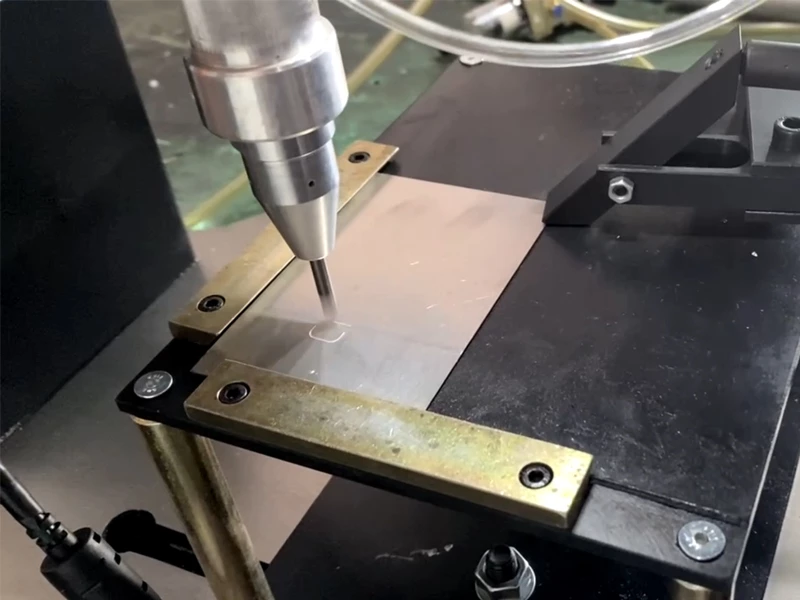

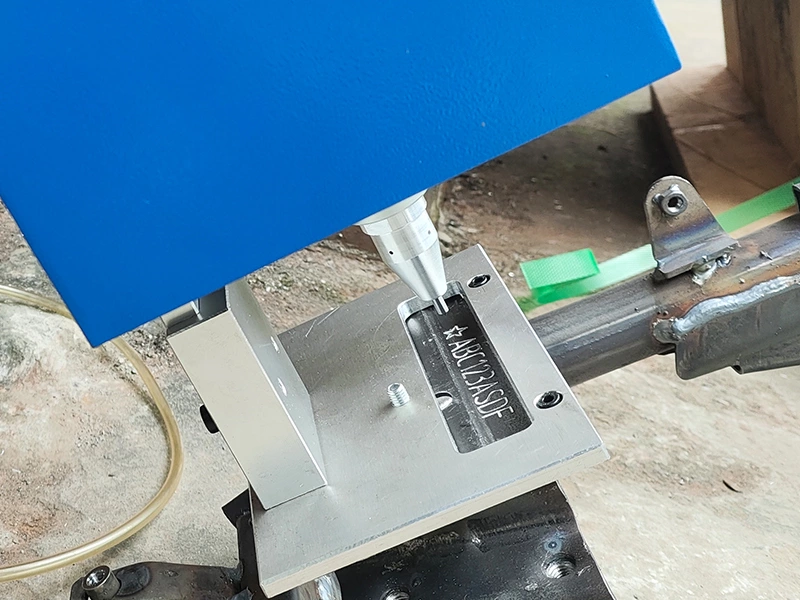

Pneumatic engraving works by utilizing a pneumatic engraver that, driven by compressed air, uses a hard alloy or diamond stylus to inscribe characters, logos, and other markings onto a material’s surface. Specifically, the pneumatic engraver employs a computer-controlled printing needle that undergoes high-frequency impact motions powered by compressed air, thereby imprinting markings of a certain depth onto the workpiece.

By watching the following video, we can more intuitively understand the operation process of pneumatic dot-peen marking vehicle VIN code.

In automotive manufacturing, pneumatic engraving is commonly used for marking vehicle identification numbers (VINs), engine numbers, and other identifiers. The pneumatic engraver creates clear VINs on metal surfaces through high-frequency impact, ensuring that each character meets depth and clarity standards. This technology not only enhances the durability of markings but also guarantees the accuracy and traceability of vehicle information.

Advantages of Pneumatic Engraving for Automotive VIN Code Marking

Pneumatic engraving equipment achieves remarkable precision, carving delicate designs in a matter of minutes. Because the technology repeats the motion with near-perfect fidelity, each incision appears at the same place and precise depth, which is a basic expectation on high-volume factory floors.

Unlike older dot-pin markers, the pneumatic units hum rather than bang, a welcome difference for workshops where noise must be kept in check for operators’ comfort or compliance reasons.

Craftspeople also appreciate that the cut depth can be dialed up or down to suit a particular job; one push of a knob changes the imprint from feather-light to trench-like without swapping out collars or changing bits.

These machines shrug off material menus that would stall weaker tools. Steel, acrylic, seasoned maple, and even polished granite pass under the nozzle without fuss, which is why manufacturers in aerospace, signage, and jewelry turn to them.

Finally, the face they leave behind is alluring in its own right. Lines are taut, letters refuse to fill with debris, and the mark survives post-process steps like sandblasting or chemical e-coat, ensuring legibility and brand integrity long after the workpiece leaves the bench.

- Easy Operation: Users can achieve precise engraving of complex patterns through simple settings, eliminating the need for highly skilled operators and reducing labor and training costs.

- Low Maintenance Cost: Pneumatic engraving machines use pneumatic drive, avoiding complex mechanical transmission components, thereby reducing daily maintenance and long-term maintenance costs.

- Environmentally Friendly and Energy-Efficient: Using compressed air as a power source, pneumatic engraving machines do not produce pollution during operation, meeting the green and environmentally friendly requirements of modern industrial production.

Selection and Usage of Pneumatic VIN Marking Machines

When selecting a pneumatic chassis number marking machine, users should comprehensively consider their production needs, workpiece materials, marking requirements, and other factors. At the same time, users should also compare and select equipment based on factors such as brand, performance, and price.

When using a pneumatic chassis number marking machine, users should strictly adhere to the operating procedures and safety regulations to ensure the normal operation of the equipment and the safety of operators. In addition, users should regularly maintain, inspect, and troubleshoot the equipment to ensure its long-term stable operation.

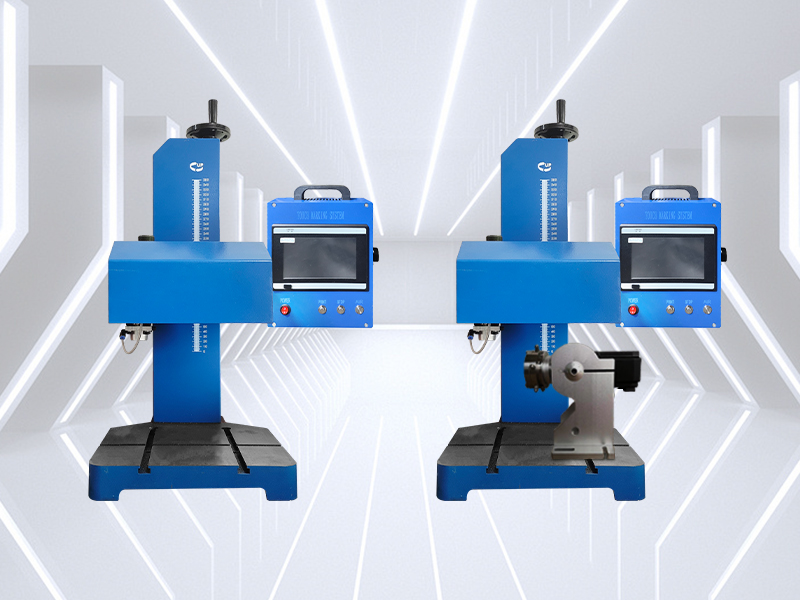

As a leading provider of pneumatic dot peen marking machines, Zixu has developed a full range of models specifically designed for metal engraving, from standard handheld units to fully customized heavy-duty automated production models.

Our best-selling marking machines are widely used in the automotive industry for manually marking VINs, chassis numbers, and engine numbers that are too large or heavy to move. They offer smooth marking results, support OEM fonts, and are easy to operate, allowing a single operator to complete the process from input to marking within minutes.

To learn more about our equipment in the automotive industry, please click here.

Recommended Products