How Cnmarking Help a Client with Pneumatic Marking Machine

Last July, a big glass company came to Cnmarking with a custom and complete proposal. They asked us for a pneumatic marking machine. They wanted the machine to provide the exact and smooth line on their bottles. The requirement of the customer was to always offer durability with the smart features with their machine. They paid us the deposit and asked us to offer the best quality machine. We started working after the conversations. We smartly plan the whole process and work together to provide the best outcome to the client. We ensure the customer that we will offer the exact quality according to your needs.

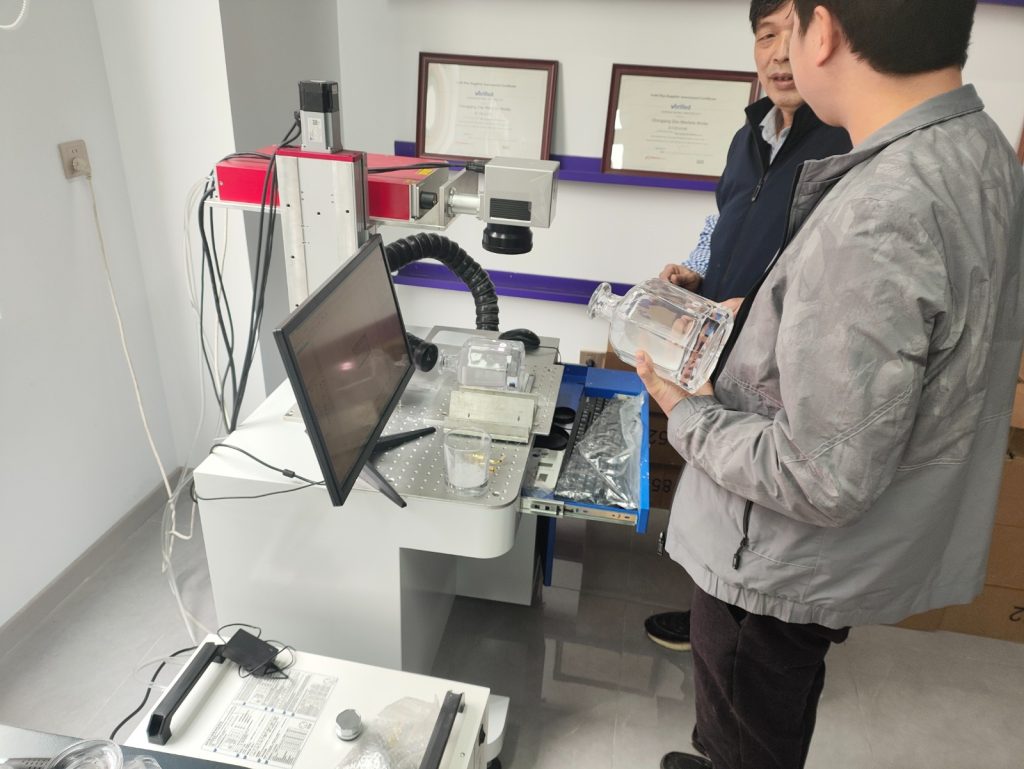

Visiting and Testing Together

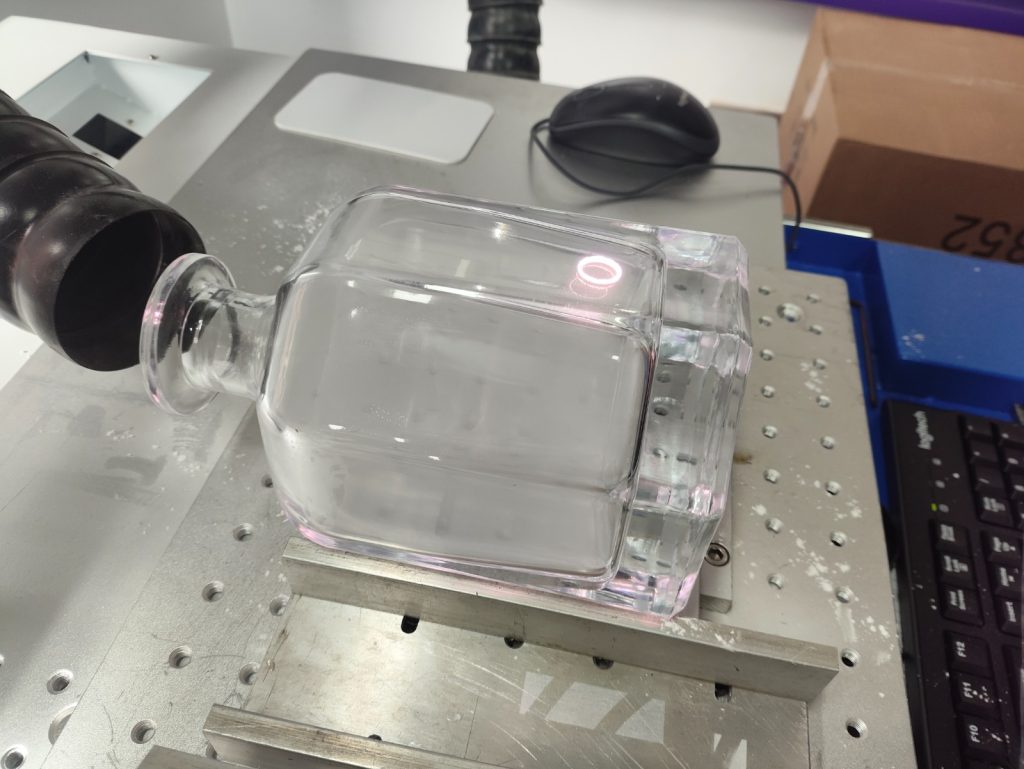

The customer brought a few glass sample bottles to our place. They were especially excited to see our portable Pneumatic Marking Machine tools up close. Our engineers put up a test right away. The air made a soft hum, and the little marking pin made a soft tap. Everyone saw the first lines come through the smooth glass clearly and deeply.

The customer had a lot of questions about pressure, air speed, and avoiding cracks. As a group, we looked at a lot of different choices. We changed the air pressure, speed, and marking depth until we were happy with the final product. The team’s smiles got bigger with each test. The day of the factory test was more than just that; it was the start of a relationship built on respect and care for each other.

Building a Custom Machine

We came up with a brand-new pneumatic dot pin marking machine that meets their needs after our meetings. The innovative tri-proof casing is the most important part of the design. Debris, grease, and moisture couldn’t get to the inside systems. Because of this, the machine lasted a long time, even in hot, dirty, or crowded places. A lot of thought went into every part, even the smallest screws and marking pins.

We made the marking head so that it can label both square and round bottles. A steel frame that is stronger and less likely to break was made. The customer was very happy when the new equipment was ready. They said they had met their goals. They were so happy with their special tool that it worked like magic that they quickly paid for it.

About the Client and Their Work

This client owns one of the biggest glass factories in China. They make hundreds of millions of dollars every year. They make beautiful perfume bottles for well-known companies around the world. You could see the bottles on the shelves of stores or in display cases. That’s why it’s so important that every mark is clear, bright, and eye-catching. The pneumatic marking machine made sure that all of the logos and words were clear.

They quickly mark each bottle because their lines move quickly. Our machine saved them both time and effort. Because of this, the bottles looked better and were stronger. With the help of the machine, it became second nature to correctly identify hundreds of bottles every day.

From Building to Delivery

The desktop pneumatic marking machine was made with a lot of skill. We looked at how to control the flow of air, pressure, and power in each part. We double-checked that everything was in order before packing and shipping. Logos and codes for the client’s brands started to show up on thick glass bottles made of the material. Every mark was made with care and attention to detail.

They noticed that their rate of production was going up quickly. The computer numerical control pneumatic marking machine never stopped working. It made sharp, straight lines on glass bottles over and over again. The customer called it the “silent helper.” Even after washing, the marks stayed bright, showing off great skill and cutting-edge technology.

Problems and Smart Fixes

There will always be issues in every attempt. A few bottles broke when they were put under pressure. Getting a steady flow of air was hard. But we kept going and came up with creative ways to solve each problem.

| Challenge | Smart Fix | Result |

| Glass breaking easily | Added finer pressure control to pneumatic marking machine | Smooth marks, no cracks |

| Dust and oil around parts | Used sealed tri-proof controller | Long and safe use |

| Uneven dot patterns | Installed CNC motion system | Clean and even dots |

| Slow marking speed | Added new fast-mark mode to handheld machine | Faster work, 25% gain |

| Vibration at high speed | Reinforced steel frame | Strong and stable body |

Each issue taught us something new. Each fix made the machine even better. We learned, improved, and built a stronger product.

Why They Chose Cnmarking

The client chose Cnmarking for simple reasons:

- We answered quickly and built fast.

- Our glass marking tests looked clean and smooth.

- Our tri-proof controller was tough and long-lasting.

They also liked how we stayed in touch. We shared progress photos, videos, and updates. Every minor detail made them trust us more.

Client Feedback On Pneumatic Marking Machine

A few days later, the client sent kind words. They said the handheld marking machine made their work easier, faster, and cleaner. The marks looked clear and did not fade. Their workers felt proud, and their customers took notice of the difference. The perfume bottles looked more elegant and professional.

Soon, the client ordered more machines for other product lines. This step helped them take on bigger projects and make even more sales. The machine became a symbol of trust, teamwork, and success.

Quick Technical Facts

| Part | Setup | Benefit |

| Controller | Tri-proof housing | Protects from dust, water, oil |

| Marking Type | Pneumatic dot pin | Clear and deep marks |

| Tested Material | Glass | Safe and smooth surface |

| Use | Perfume bottle branding | Bright and neat look |

| Power | Air + Electric | Steady marking motion |

| Frame | Steel body | Strong, stable, and long-lasting |

Key Takeaways

- Cnmarking designs strong pneumatic marking machines for all industries.

- Each custom machine is tailored to meet the specific needs of a particular factory.

- Testing helps reach perfect marks every time.

- Every update and fix adds more value for clients.

We keep learning from each project, constantly growing and improving.

This story demonstrates how care and teamwork yield significant results. Cnmarking took one idea and turned it into a strong, intelligent machine that works fast and efficiently. From the initial chat to the final test, every step was marked by passion and effort. Now, that glass factory makes perfume bottles that shine across the world.

FAQs

- Can it mark glass safely?

Yes! The pneumatic marking machine can mark glass, metal, and more with complete control.

- Is it easy to use?

Yes! The portable marking machine is lightweight, easy to move, and quick to start.

- How can I buy one?

You can see our marking machines for sale on the Cnmarking website.

- Can it be customized?

Yes! We design CNC pneumatic marking machines to meet your specific needs and ideas.