What You Need to Know about Name Plate Engraving

Nameplates are indispensable for identification purposes for equipment, machines, and other tools. For branding, compliance, or traceability purposes, a well-engraved nameplate is professionally made and enduring. Out of the many engraving techniques, laser marking stands out because it is precise, durable, and the most popular option.

This is a guide to laser engraving and its applications, its marking applications, pin marking, its dependent industries, and its engraving service providers.

Why Laser Marking is Essential for Nameplates

When it comes to marking nameplates, laser engraving is the best choice for precision and durability. Unlike other techniques, laser etching creates permanent marks that stand up to tough conditions, including chemicals, abrasion, and extreme heat. Because of this, important information like serial numbers, safety warnings, and compliance labels is always readable for the entire lifespan of the product.

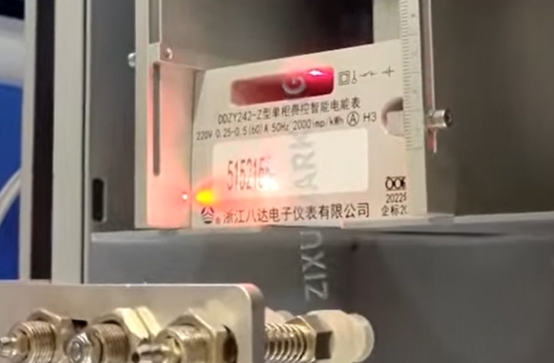

Traceability is increasingly important across different industries, and another benefit of laser systems is that they can engrave intricate designs, ultra-fine text, and even machine-readable codes like barcodes or QR codes. This process is effective because it allows for quick automation with low to no setup, making it ideal for small and large-scale production.

Laser engraving offers marking for numerous materials, plastics, metals like stainless steel, aluminum, and brass, as well as coated nameplates. Unlike other engraving methods, laser engraving does not use inks or dyes, which can be harmful to the environment. This makes it a clean, long-term cost effective, cost-effective marking solution.

Applications and Benefits for Laser Engraving Nameplates

Not only does laser engraving mark and personalize nameplates for industrial and personal uses, but it also opens the creative and functional avenues of engraving. Laser engraving is incredibly versatile, so from compliance markings to personal touches, it has endless applications.

- In healthcare, laser engraving nameplates assist in meeting needs such as marking surgical tools and equipment. By engraving serial numbers, barcodes, and manufacturing data, laser engraving aids compliance with UDI (Unique Device Identification) requirements for unique and bulk identification.

- In the automotive or electronics industries, nameplates for components are often laser engraved to mark identification, traceability, and safety assurance. Laser engraving also assists in the precise manufacturing of parts.

- Engraving not only assists companies and institutions, but individuals as well. Jewelry, trophies, and plaques are often engraved with names or dates, but pets, knives, and firearms can also bear engraved nameplates for identification or decorative purposes.

Another often explored perk of laser engraving is the assortment of materials it works with. Stainless steel, anodized aluminum, coated plastics, and acrylic are just a few examples. This is why both bulk manufacturers and custom project designers greatly benefit. Additionally, the mark is as permanent as it is precise and is resistant to wear, ensuring that essential and critical information is not only engraved, but remains readable and intact over time.

Major Differences Between Pin Marking and Laser Engraving Nameplate

When choosing a nameplate marking method, two common technologies are pin marking and laser engraving. Nameplate marking depends on the nameplate material and the marking method. Both methods serve the same purpose, but have differences in execution efficiency, details, and other considerations important to modern production.

- Pin marking, or dot peen marking, leaves a discrete font. In most cases, this marking method makes small dots or scratch lines. Basic identification, such as marking a name, is easily achievable; however, peripheral details, font sizes, and replication speed are problematic. Further, over the years, maintenance becomes a necessity due to the slow and vibrating noise, pin marking reproducibility, and pin dulling.

- In contrast to pin marking, laser engraving does not contact the material processed, thus making it possible to deeply cut or vaporize its surface without touching it. The result is deep and clean marks without contact. Barcodes, logos, and serial numbers can be marked in a sophisticated, quick, and noiseless manner. The absence of contact makes it possible to etch on fragile items. These machines are easier to clean and take care of, and do not demand much of a speed or sound system compared to mechanical laser systems.

In conclusion, when it comes to industries that need clean, long-lasting markings done quickly, laser engraving stands out for its effectiveness, precision, and engrave quality. In comparison to other engraving techniques, it provides much greater effectiveness. With manufacturers shifting to automated systems and smart manufacturing, laser nameplate engraving gives a convenient, aesthetically pleasing, and functionally effective option for modern-day needs.

Where to Find a High Quality Name Plate Engraver?

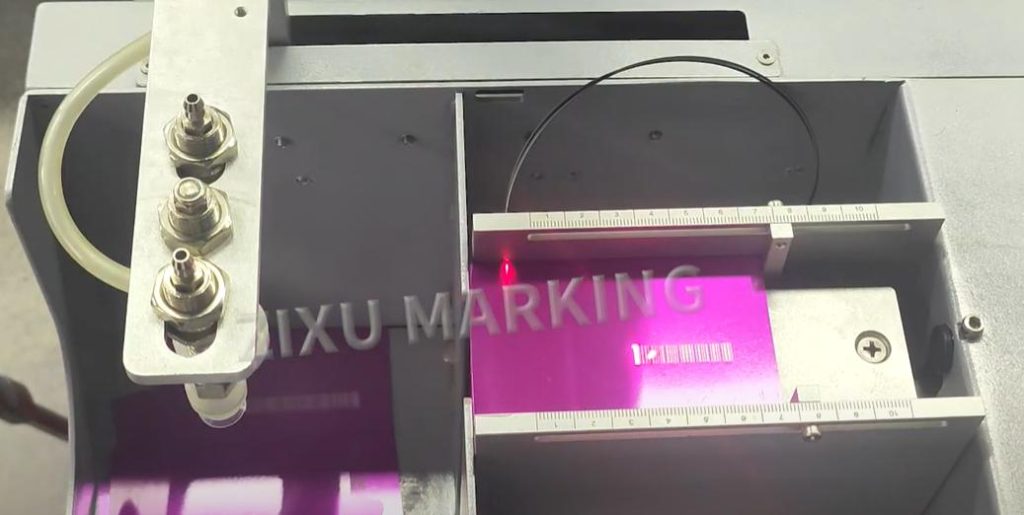

When looking to invest in a reliable metal nameplate engraving machine, ZIXU is at the forefront of the industry. Zixu focuses on optimally mastering nameplate engraving lasers mark machines to ensure the rigorous standards of engraving accuracy are met. We manufacture and sell compact desktop units and fully enclosed industrial systems, and we ensure all are made to be accurate, reliable, and user-friendly.

With Zixu’s Nameplate laser engraving machines, crisp and high-contrast marks can be made on aluminum, brass, and coated stainless steel. Intelligent software enables the importing of CAD drawings, barcodes, QR codes, and even vector art. Moreover, real-time monitoring tools provide control over the whole process.

Beyond the hardware, we provide customers with on-site installation, operator training, and even 24/7 technical assistance. With a certified partner network, customers can access local services for spare parts which ensures the nameplate marking operation is always running. From provided flexible solutions for custom runs to high volume engraving machines, Zixu is unmatched in industry reputation and engraving precision.

Summary: Make Your Nameplates Stand Out

For industries needing permanent name and compliance engraving, laser-engraved nameplates offer precision, engraving accuracy, compliance, and durability. Compared to and pin marking, laser engraving and pin marking is faster, more versatile, and cost-effective.

Traceability, business branding, and safety compliance needs all can leverage high-quality laser engraving. Investing in Professional engraving will make sure your nameplates stay legible and professional for years.

Looking for a nameplate tailored to your specifications and highly durable? Get in touch for your customized solution!

Recommended Products