Troubleshoot the Faulty Dot Peen Marking Machines

In general, it is best to diagnose and repair dot peen marking machines on-site when they malfunction. Otherwise, you will have to wait for a replacement to be shipped, which will affect your production, even if you purchase a new machine. Replacement markers, especially customized ones for automation, may have underlying issues with data interfaces and system compatibility. Therefore, choose a brand that offers adequate after-sales and technical support.

Next, I will explain how dot peen marking machines work and provide examples of common issues. Hopefully, you will have a better understanding of how these machines work and be able to quickly determine the cause of a problem before contacting us or other brands from which you have purchased products. This will reduce the time it takes to communicate with us.

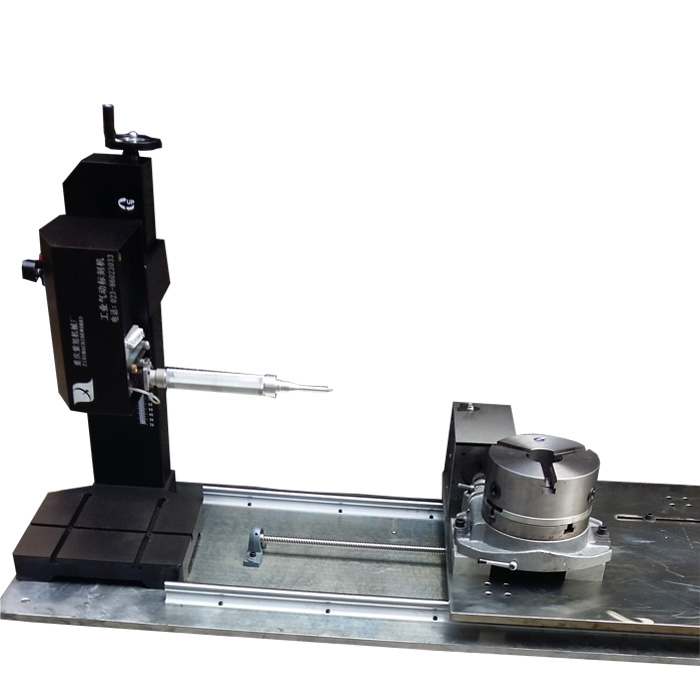

How Does a Dot Peen Marker Work?

In short, you enter content into the controller, which converts it into electrical signals containing X and Y coordinates. These signals are transmitted to the drive motor, which moves the carriage of the marking needle to the correct coordinates. Finally, a pneumatic regulator or motor propels the needle to strike the workpiece surface at a specific frequency and torque, creating a permanent mark of a certain depth. Even with customized automation systems, additional actions are carried out before or after marking using a controller or PLC.

How To Troubleshoot?

Controller Black Screen

A black screen on the controller may indicate a connection issue or hardware failure. First, check for loose wires or damaged cables between the display and the control panel. Inspect the electrical wiring and connector pins for signs of wear, corrosion, or improper seating. If the screen remains unresponsive after reseating connections, the issue may lie with a faulty display panel or control board. In such cases, replacing the defective component is necessary. Additionally, verify the power supply to ensure stable voltage, as fluctuations can also cause display failures.

Marking Needle Shaking or Not Marking

If the marking needle shakes excessively or fails to mark, the root cause could be:

- Faulty communication between the control board and the marking head (check data cables and connectors).

- A malfunctioning regulator affecting needle movement.

- A damaged needle holder is causing instability.

To diagnose, inspect each component individually. Test the control signals, ensure proper power delivery to the regulator, and examine the needle holder for cracks or misalignment. Replacing worn-out parts or reseating connections often resolves the issue.

Marking Content Distortion

Distorted markings can result from multiple factors:

- Loose marking needle: Tighten it using an appropriate wrench.

- Dust accumulation: Excessive dust creates friction between the needle core and sleeve, leading to erratic movement. Disassemble and clean the sleeve if necessary.

- Control board or communication errors: Check for damaged cables, loose plug-ins, or electromagnetic interference (EMI) from nearby equipment.

- Damaged needle tip: A bent or worn needle can cause irregular markings.

Isolate each potential cause by testing different components and replacing faulty elements.

Needle Tip Stuck

A stuck needle tip is commonly caused by:

- Excessive air pressure: Some operators use pressure near or beyond the design limit to achieve deeper markings, which can break the needle spring and cause jamming. Always operate within recommended pressure ranges.

- Dust buildup: Heavy dust can clog the narrow gap between the needle and sleeve, restricting movement. Disassemble the marking needle, clean the internal components, and lubricate if necessary.

Regular cleaning and pressure checks can minimize these issues. If the needle remains stuck after cleaning, inspect for mechanical damage and replace any broken parts.

By systematically diagnosing these problems, you can maintain optimal marking machine performance and reduce downtime.

Marking Needle Breakage

The most common problem is that the marking needle is not perpendicular to the work plane. This often subjects the needle to lateral stresses, which can result in chipping or breakage. Customers using conventional dot peen marking machines to mark thin, round tubes are particularly susceptible to this problem. For these types of tubes, as well as gas cylinders, flanges, and other similar components, we use specially designed extension needles with a longer amplitude to address the issue. You can minimize this issue by selecting one of our marking machines or needles.

Recommended Products

.jpg)