Continuous vs. Pulse Laser Cleaning: Choose Which One?

Laser cleaning has quietly grown into a workhorse for removing rust, oil, paint-any contaminant that stubbornly clings to metal, glass, or stone. The method essentially hurls concentrated light at a surface, turning dirt into vapor just as quickly as it turns the laser energy into kinetic force. Researchers usually sort the practice into two camps: pulsed-laser applications that deliver bursts of energy and continuous-wave setups that drown a surface in a steady beam. Both strategies share the same physical principle, yet they drum up very different results and practical advantages.

What are Continuous and Pulse Laser Cleaning Machines?

Pulse Laser Cleaning Machines: These machines utilize short, high-energy laser pulses to ablate contaminants from the surface. The pulses are typically generated by solid-state lasers, such as Nd: YAG or fiber lasers. The short duration of these pulses minimizes heat transfer to the underlying substrate, making them ideal for delicate materials.

Continuous Laser Cleaning Machines: These machines employ a continuous laser beam to heat and remove contaminants through thermal processes. The continuous nature of the beam allows for efficient cleaning of larger areas and can be achieved using various laser sources, including CO2 lasers and some fiber lasers.

Differences Between Continuous and Pulsed Laser Cleaning

There are some differences between continuous laser cleaning machines and pulsed laser cleaning machines. The most significant difference is that continuous cleaning machines are more suitable for long-term, continuous cleaning tasks, while pulsed cleaning machines are designed for short-term cleaning tasks that require high-efficiency removal of contaminants.

Operational Principle Differences:

- Pulse: Operates by delivering short, intense bursts of energy that cause rapid material removal through ablation. This process involves the rapid vaporization and ejection of contaminants.

- Continuous: Operates by heating the surface and causing the contaminants to expand, crack, and eventually detach. This can also involve melting or vaporization of the contaminants.

Application Scenario Differences:

Pulse cleaning machines:

Pulse cleaning machines employ intense pulsed laser beams to rapidly remove surface contaminants and deposits. The working principle involves the instantaneous release of laser power to rapidly heat and even vaporize surface attachments, achieving the cleaning effect. Pulse cleaning machines offer faster cleaning speeds and are suitable for tasks requiring quick and efficient cleaning.

- Delicate materials like glass, ceramics, and plastics

- Cleaning intricate geometries and delicate surfaces

- Applications requiring high precision and minimal heat-affected zones, removing thin or layered contaminants

- Archaeological artifact cleaning and restoration

Continuous Laser Cleaning Machines:

Continuous laser cleaning machines are ideal for applications demanding sustained cleaning. These machines utilize a laser beam to effectively remove residual dirt and particles from surfaces, ensuring consistent results over extended periods.

- Removing heavy contaminants like paint, rust, and scale from large surfaces

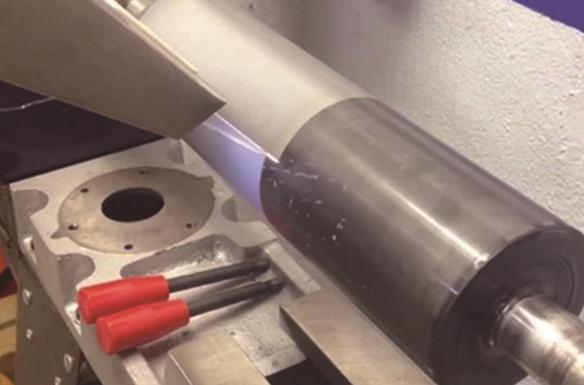

- Industrial applications such as cleaning molds, dies, and machinery

- Cleaning large areas quickly and efficiently

- Applications where higher throughput is required

Suitable Material Differences:

- Pulse: More suitable for materials sensitive to heat, such as plastics, polymers, and some metals.

- Continuous: Can be used on a wider range of materials, including metals, ceramics, and some plastics. However, it may cause more heat-affected zones on heat-sensitive materials.

Pros & Cons of Pulse and Continuous Laser Cleaning Machines

Advantages and Disadvantages of Pulse Laser Cleaning

Advantages: Laser cleaning produces exceptionally precise results while generating only a small heat-affected zone. It is therefore well suited to fragile materials and complex shapes that would distort under harsher treatments. The method can tackle a broad array of jobs, especially those demanding fine control and minimal risk of damage. Furthermore, lasers integrate easily into automated workplaces, often pairing with marking heads so that parts are cleaned and branded in a single pass.

Disadvantages: By contrast, the technology usually demands a higher up-front investment than simpler, continuous-cleaning rigs. Because each pulse addresses only a small area, overall throughput drops when the operation scales to large quantities. For the same reason, system configuration and day-to-day operation can grow noticeably more intricate, requiring skilled personnel to manage the equipment.

Advantages and Disadvantages of Continuous Laser Cleaning:

Advantages: Laser cleaning delivers high throughput, making it economical for extensive cleaning jobs; it handles heavy soiling with speed and removes tough industrial deposits reliably. The system also requires only a straightforward setup, allowing quick deployment on the shop floor.

Disadvantages: Because the process generates heat over a wide area, sensitive materials can suffer warping or surface damage. The technique is therefore ill suited to fragile components or complex shapes, and it offers less fine control than pulsed-laser cleaning.

Pulse vs. Continuous Laser Cleaning Machines: Which is Right for Your Needs?

Selecting the appropriate laser cleaning method depends on several factors:

Cleaning Requirements

- Material properties: Surfaces react differently under laser light, so metals, plastics, and ceramics must all be assessed for hardness, reflectivity, and thermal conductivity before work begins. In other words, a stainless-steel plate, an aluminum housing, and a glass lens can each behave in unexpected ways the moment the beam sweeps across them.

- Cleaning goals: Before activating any system, clarify whether the task is to strip away grime, oil, or paint or to fight stubborn rust, remove thick oxides, or renew a bond-ready finish. Accurate goals help match the technology and settings to the result that equipment operators and engineers expect.

- Surface geometry and complexity: Every user should ask how many corners, holes, welds, or curves a part presents, since rough or tight shapes raise the need for motion control, scanning speed, and focal depth that can follow the contours without overheating any edge.

Laser Equipment Performance

- Power and energy density: Continuous-wave units deliver steady high power over large areas and can sweep across whole molds or bulk components quickly. Pulsed systems, meanwhile, concentrate energy into brief bursts that melt or fracture contaminants without always warming the substrate, so they suit fine work on small parts, delicate molds, or highly polished surfaces.

- Beam quality: A tighter, highly stable focus lifts removal rates and lowers the risk of damage, so users must compare M-squared values, divergence angles, and other metrics against manufacturers claims. The better the beam, the less time, money, and rework are needed.

Material Characteristics and Cleaning Effects

- Thermal sensitivity: A CW beam can fill a thin part with heat and warp it, while short pulses put almost no energy into the bulk metal. Operators must therefore match the cooling capacity of the substrate to the dwell time of the pulse.

- Cleaning efficiency and quality: Finally, lab tests and field data should track cleaning speed, contamination weld-through, and gloss or Ra values so that teams can rank one process against another and defend their equipment choices.

Cost and Maintenance

- Acquisition and operating expenses: Continuous-wave laser cleaners usually command a steeper initial price yet deliver superior throughput on extensive cleaning projects. In contrast, pulsed systems cost less to buy but often demand more regular tuning and on-site attention.

- Routine upkeep and service: The two technologies present distinct servicing needs. Therefore, assess each model’s reliability and how steadily it holds output quality over time.

Try the Latest Eco-friendly Cleaning Method

Choosing between pulse and continuous laser cleaning requires careful consideration of the specific application, material properties, and desired outcomes. By carefully evaluating the factors discussed in this article, you can select the most suitable laser cleaning solution for your needs, whether it’s for delicate microelectronics components, large industrial equipment, or anything in between.

Zixu offers a range of high-quality laser cleaners, including continuous-wave (CW) models for industrial applications and more versatile pulsed laser cleaners for finer cleaning. Both utilize high-energy laser beams to effectively remove rust, paint, coatings, oils, inks, and other contaminants from various metallic and non-metallic surfaces. These laser cleaning methods eliminate the need for mechanical abrasion, detergents, or harmful emissions.

Recommended Products