Easy Cost-Effective Packaging with CO2 Laser Marking Machine

A Chinese company that makes high-precision instruments and machinery had a costly packing problem. Their top priority is getting their products to the European Union market. In some EU countries, it was against the law to put standard A4 shipping labels on boxes. Instead, they ordered custom-printed wooden boxes.

The price for each set of boxes is tens of thousands of yuan. A coworker in the instrumentation field told them to check out Chongqing Zixu Machine. They were told about a flying CO2 laser marking machine that could be used instead of their old method. This is an example of how a customer saved time and money by using a CO2 laser system to label regular containers with all the information they needed.

Challenges Before Implementation

High Cost of Custom Packaging

Before this, the customer had to order special export containers. Each custom crate had the company’s logo and shipping information on it. It took a lot of time and work to make these containers. Building these kinds of containers can be “expensive and time-consuming,” especially when trying to follow strict export rules. The cost of things like wood and plywood has also gone up. The cost of packaging for each shipment was very high, taking up a large part of the company’s budget.

Inefficient and Error-Prone Labeling

The customer couldn’t use regular paper labels for shipments to the European Union. Staff members had to use a portable inkjet printer. They printed the shipping information in many parts and then put it on the boxes. It was a slow and awkward process. When you enter and print data by hand, mistakes happen a lot. It took more time and effort to set up and place each label. This made the process more likely to go wrong. For instance, if any information was missing or wrong, it could cause delays in shipping.

The labeling process was mostly ineffective and could have caused errors.

Slow Shipping Preparation

Making custom crates and labeling multiple parts caused delays in shipping. Making each set of big wooden crates can take a day or more. The next step was for the staff to print and prepare the labels by hand. Getting a cargo ready was hard work because of all these steps. Trying to speed up packaging caused delays in delivery and made employees do boring tasks that slowed them down. To meet the client’s deadline, we had to speed things up by getting rid of extra steps and automating as many as we could.

Solution Selection

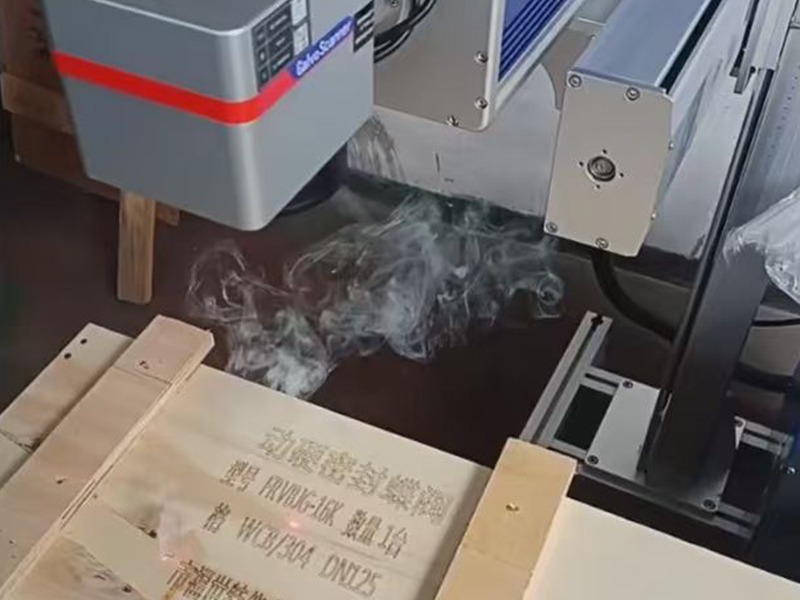

The aerial CO2 laser marking machine from Chongqing Zixu Machine was the answer. This dynamic laser system can engrave all the information you need onto simple wood boxes in one go. We chose it for our first design tests because it could work in “static marking test” mode. The CO2 laser makes clean, exact cuts in paper and wood. It uses a focused beam of light to permanently etch the data, so there is no need for ink or other materials. We added a big touchscreen controller that lets users enter shipment information or pick from a library of pre-made label designs.

Key Benefits & Results

- Versatile laser engraving: The CO2 laser can mark wood crates, leather, polymers, and a lot of other things. This makes it a very useful tool for engraving.

- High-speed marking: The flying laser can mark at speeds of up to 130 m/min, which makes it great for high-speed marking.

- No consumables: Because CO2 marking doesn’t use ink or chemicals, it doesn’t need any maintenance or waste.

- Integrated control: You can type in data or click on pre-made labels with a touchscreen, which cuts down on the amount of work that people have to do by a lot.

- Eco-friendly: We make our packaging more eco-friendly by not using plastic labels and ink and instead engraving directly on the packaging.

Implemented Solution

Equipment Setup

We set up the aerial CO2 Laser Marking Machine equipment at the same time as the packaging process. A 10.2-inch touchscreen controller makes it easy for users to operate the CO2 laser marking machine. While working in static mode, engineers made small changes to the marking scheme on sample boxes. You only need the laser unit, the power source, and the sensors. You don’t need any other hardware, like stamps or printers. We put the CO2 laser head and lens on top of the crate route, and we set up a photocell sensor to find out where each crate was. It’s easy to set up.

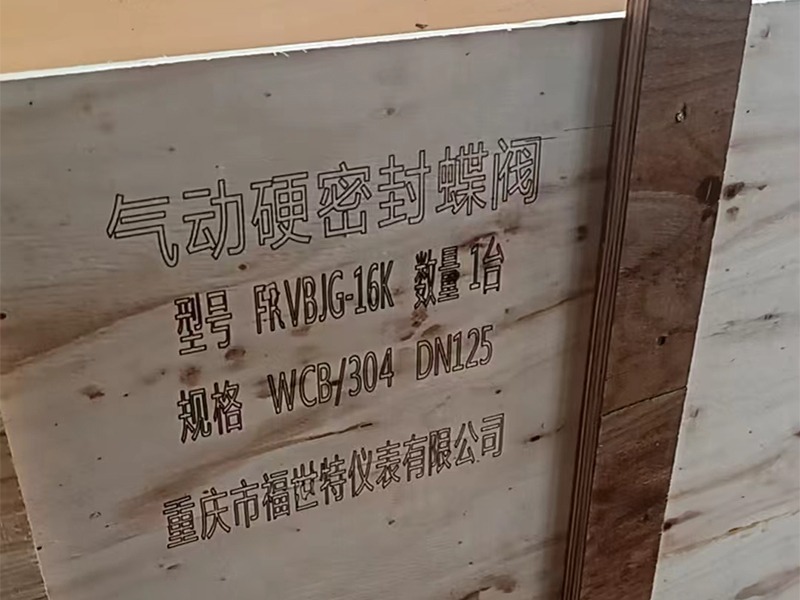

Application

The system is now working, so operators can easily label each cargo box. They put the mailing address, logo, and contents on the screen. You can also add a serial number or bar code to a template. The CO2 laser marking machine can engrave the whole crate in one pass with the laser. This is better than the old way of printing out a lot of paper labels by hand. Keyence says that “laser marking wood is a one-and-done method” that leaves “clean, permanent” markings.

New Packaging Strategy

The customer has chosen to buy plain, eco-friendly wood boxes instead of ones with prints on them. These empty shipping containers are easier to get to and cost less. We use our CO2 Laser Marking Machine to brand and label things. It’s a big time saver that you don’t have to print each box ahead of time. The new method saves a lot of money because the customer can now use information templates again and again without having to pay extra for special printing.

This method is very good for the environment, which is very important. You can reuse or recycle wooden boxes, and CO2 labeling doesn’t need any inks or solvents. Laser marking is a faster, cheaper, and better for the environment way to mark wood than stamping or inkjet labeling.

Optimized Workflow After Implementation

When the CO2 Laser Marking Machine technology was put into use, the packing process became much easier. The team can now start the marking cycle by putting the plain container under the laser and entering or scanning the shipping information on the touchscreen. The CO2 laser marking machine automatically stamps each label on all four sides in just a few seconds. This one computerized process replaces a lot of manual ones.

- Before, operators had to enter shipping information by hand or use a template that was already filled out.

- The CO2 laser marking machine goes over the moving cargo once and marks all the text and barcodes it needs to.

- You don’t need handheld printers or printed labels.

- The system’s database and templates take care of data entry, which cuts down on mistakes.

- The new process’s streamlined operation has led to a huge increase in throughput.

Results and Business Impact

Significant Cost Reduction

Switching to laser marking cuts costs by a large amount. The company has cut back on how much it spends on custom crate printing and labels for consumables. Chongqing Zixu’s low price CO2 laser marking machine made the investment quite reasonable. According to industry data, the cost of ink or labels will be much higher than the cost of a laser at first. The client thinks they will save tens of thousands of yuan a year by not having to pay for custom printing.

They have saved money on materials by only using simple wooden boxes. These yearly savings more than make up for the cost of buying a CO2 laser marking system.

Improved Efficiency

The laser made work much more productive. Now we can label each box in seconds instead of spending a lot of time getting everything ready. Laser marking speeds up crate throughput because it is quick and easy to do. It used to be a problem in the packaging process that you had to wait for labels to print or dry. Because laser marking on wood only took a few seconds, experiments could run at high speeds.

Operators can now spend more time on other tasks, like making the packaging better. But manual labeling is no longer a problem. Overall, this has made the workflow better by speeding up package delivery and taking the boring job of labeling off of workers’ hands.

Advanced Flexibility

The new approach is all about being flexible. The customer can now change the packing details at any time. You can add any text or logo to plain crates whenever you want, unlike fixed-printed ones. You can easily switch between different label templates with our system to meet the needs of different EU countries. This dynamic CO2 laser marking tool marks every surface of the container equally well. For example, batch numbers or handling instructions could be added if needed. Laser marking works on a lot of different materials, so you can use the same tools to mark cardboard boxes and plastic pallets.

Enhanced Compliance and Quality

Laser labeling made both the look of the product and its compliance much better. Laser-engraved markings will always be clear, no matter what happens. They won’t wear off like stickers or ink because they are resistant to water and stains. These marks will last a long time and meet EU import rules. For all intents and purposes, the laser markings are like permanent labels that are built into the box. Also, the laser beam is smaller than a human hair, which makes the marks clearer and more accurate.

Scanning barcodes or laser marks is more reliable than reading addresses from printed paper. Client said that laser markings are easy to read even when parts are in harsh conditions. The new crate labels will make it easier to track things and make fewer mistakes at customs.

Key Benefits & Results

- Cost Savings: Eliminated the expense of custom crate printing and label consumables.

- Speed: Each crate is marked in a single, quick laser pass, significantly reducing preparation time.

- Flexibility: Plain crates and digital templates allow instant label changes.

- Quality: High-resolution, permanent marks meet international standards.

- Eco-Friendly: No inks or chemicals are used, reducing waste.

- Reliability: Automated marking removes manual error and oversight.

These benefits resulted in tens of thousands of yuan saved per year and significantly faster shipping.

Client Value Summary

By adopting Chongqing Zixu Machine’s CO2 laser solution, the client transformed its export packaging. The CO2 laser marking machines replaced manual steps with an automated, one-step marking process. The savings from using plain crates and eliminating labels have paid back the investment many times over. The company also avoids the hidden costs of labeling errors and shipping delays. The client gained a highly cost-effective and adaptable packaging strategy. They now have one of the best CO2 laser marking machine setups for their industry.

This case demonstrates how a flying CO2 laser marking machine can address complex packaging challenges. The carbon dioxide CO2 laser marking machine from Chongqing Zixu Machine delivered a flexible, low-maintenance solution that pays for itself. In the end, the client achieved easy, cost-effective EU packaging