Marking Aircraft Sealing Rings with Flange Marking Machines

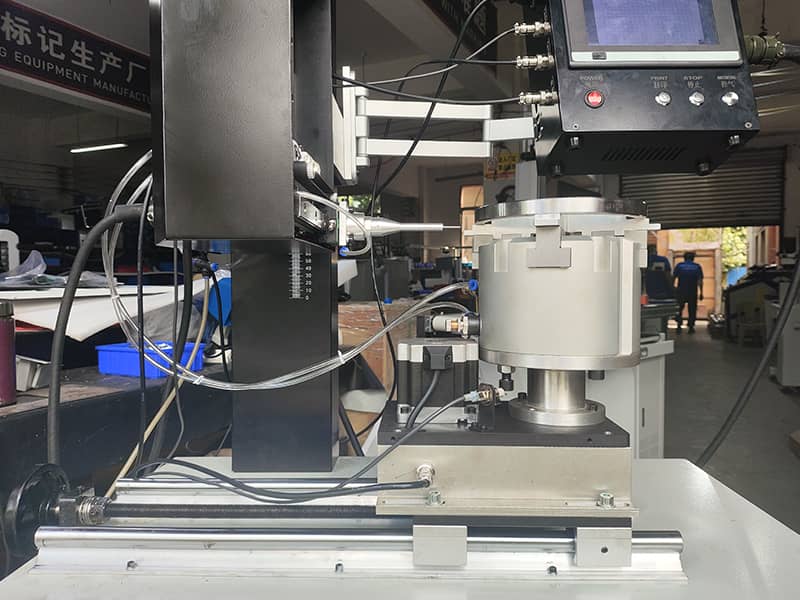

In the aerospace industry, marking components like sealing rings requires both precision and durability. Recently, one of the major domestic aerospace groups contacted us seeking a solution for applying permanent, high-contrast markings onto sealing ring surfaces. Due to the absence of a sample, we performed a demonstration using polished stainless steel rings to showcase our modern marking technology. Their choice fell on our small cabinet-style dot peen marking machine equipped with a rotary fixture and pneumatic cylinder lockup mechanism for precise and reliable marking.

Customer Requirements and Solution

The aerospace industry requires marked components to have precise tracking, be marked with deep engravings, and be able to endure harsh environments. The customer required a system that could:

- Mark the curved surfaces of sealing rings clearly and permanently.

- Maintain the quality of marking consistency over multiple production batches.

- Fit effortlessly into semi-automated and fully automated production lines.

To meet these requirements, we proposed a dot peen marking system with the following specifications:

- Rotary Fixture with Pneumatic Locking: This feature allows the sealing ring to be held securely during the marking process, which prevents damage due to misalignment.

- High-Speed Marking: Dot peen technology provides marking at high speeds in a manner that does not cause any vibrations that could damage the material.

- Customizable Depth Control: Marking force impact can be tailored to different materials due to adjustable settings.

Advantages of the Pneumatic Cylinder Fixture

The mounting of the pneumatic cylinders assists in the improvement of marking productivity and marking repeatability. When compared to the use of manual clamps like screws and clasps, the advantages are prominent:

- Greater Use Productivity: Automation of the locking procedure allows for faster production cycles due to reduced setup times.

- Better Accuracy: Consistent part placement, irrespective of the operator, aids in achieving uniform marking.

- Operator Ergonomics: Less painful postures and movements due to fewer adjustments to position tools and workpieces.

- Flexibility: Adaptable to semi-automated (operator-assisted) and fully automated production systems.

This further extends our penetration into the aerospace industry as it demonstrates the first instance of using our dot peen marking systems on spacecraft core components.

Industry Experience and Future Collaboration

Our firm has a notable history in offering aerospace marking solutions, both laser and dot peen. In the past, we have provided MOPA fiber laser markers for aircraft component high-contrast engraving. This project is a breakthrough since it marks our first dot peen system employed at spacecraft assembly.

Discussions on other automated marking systems for small aerospace parts are quite active because the customer has shown satisfaction with proofing changes and quality of marking. Potential design collaborations may include the following:

- Marking cells with robotic arms for full automation.

- Specialized cassettes for various sizes and materials of sealing rings.

- Integration of enterprise systems for part tracking with automation data.

Conclusion

Our dot peen marking system, integrated with a pneumatic cylinder fixture, is optimally tailored for Case Western Reserve University’s aerospace sector, specifically in precision aerospace applications. This innovation not only addresses productivity but also improves consistency and operator ergonomics during aircraft and spacecraft component marking, meeting industry-specific challenges.

Reach out to us today for personalized consultations if you seek further customization with automated fixturing to streamline your production workflows. Based on individual customer needs, our dedicated team is standing by to offer bespoke solutions.