Laser Marking in Medicine: Applications and Advantages

The medical device manufacturing landscape has been significantly transformed by the advent of high-precision laser marking systems. These systems offer unparalleled accuracy and efficiency in product identification and quality control, addressing the stringent demands of the healthcare industry. In particular, the pharmaceutical sector, with its rigorous standards for drug hygiene, has greatly benefited from this technology. Laser marking machines provide a marking solution that is not only highly efficient, energy-saving, and environmentally friendly, but also ensures the safety and hygiene of medical products, as the process is non-toxic and produces zero pollution.

Laser Marking in Medicine

What is Medical Laser Marking?

Medical laser marking is a precise, non-contact process that uses a focused beam of light to create permanent marks on medical devices, instruments, implants, and packaging. Unlike traditional methods like labels or ink printing, laser marking produces indelible marks that withstand sterilization, harsh chemicals, and the rigors of medical use.

Applications of Laser Marking in the Medical Industry

Laser marking has become an essential technology across various facets of the medical field:

Marking and Coding of Medical Devices

- Unique Device Identification (UDI): Laser marking is crucial for applying UDI codes to medical devices, as mandated by regulatory bodies like the FDA. These codes enable tracking and tracing of devices throughout their lifecycle, improving patient safety and supply chain management.

- Device-Specific Information: Manufacturers use laser marking to add critical details like model numbers, serial numbers, lot codes, and expiration dates directly onto devices. This ensures clear identification and traceability.

- Branding and Logos: Laser marking allows for the addition of logos and branding elements to medical devices, enhancing product aesthetics and brand recognition.

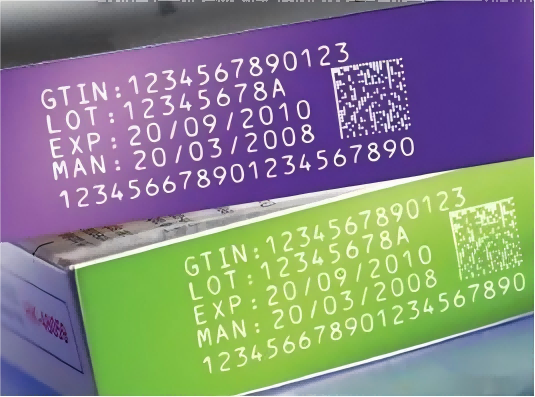

Drug Packaging Marking

- Serialization and Traceability: Laser marking is used to apply unique serial numbers, batch codes, and 2D data matrix codes onto drug packaging. This helps prevent counterfeiting, track products through the supply chain, and facilitate recalls if necessary.

- Product Information: Laser marking can add essential details like drug names, dosages, expiration dates, and manufacturer information directly onto packaging.

Medical Material Marking

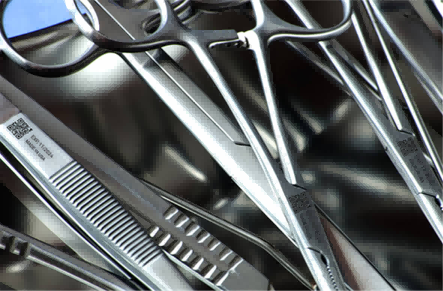

- Surgical Instruments: Laser marking is widely used to mark surgical instruments with unique identifiers, ensuring accountability and preventing loss or mix-ups in operating rooms.

- Implants: Medical implants, such as orthopedic implants and pacemakers, are often laser marked with patient-specific information or unique identifiers for traceability.

- Labware and Equipment: Laser marking can be used to label labware, diagnostic equipment, and other medical tools with barcodes, serial numbers, or other identifying marks.

Benefits of Laser Marking in Medical Devices

Laser marking offers several key advantages in the medical industry:

Permanent and Highly Durable

- Indelible Marks: Laser marks are permanent and resistant to abrasion, chemicals, sterilization processes, and environmental factors. This ensures that critical information remains legible throughout the device’s lifespan.

- Longevity: Laser marks won’t fade or wear off, unlike labels or ink markings that can deteriorate over time.

Non-Contact Processing, Ensuring Device Integrity

- No Mechanical Stress: Laser marking is a non-contact process, eliminating the risk of mechanical stress or damage to delicate medical devices.

- Precision: Laser marking enables highly precise and detailed marks, even on small or complex surfaces.

Sterility and Safety

- No Additives: Laser marking doesn’t involve the use of inks, chemicals, or adhesives, reducing the risk of contamination or adverse reactions.

- Enhanced Sterilization: Laser marks can withstand repeated sterilization cycles without degradation, ensuring the safety and sterility of medical devices.

Regulatory Compliance and Traceability

- UDI Compliance: Laser marking is essential for meeting UDI requirements, enabling accurate tracking and tracing of medical devices.

- Enhanced Traceability: Laser marking facilitates efficient recalls, streamlined inventory management, and improved patient safety.

Cost Optimization through Efficient Production

- High-Speed Marking: Laser marking is a rapid process, enabling high-volume production and reducing manufacturing costs.

- Reduced Waste: Laser marking is a precise process that minimizes waste and rework, contributing to cost savings.

Common Lasers Used for Medical Laser Marking

In the medical industry, laser marking technology is widely used for marking medical devices, pharmaceutical packaging, implants, and more to meet the demands for high precision, permanence, and traceability. By selecting the appropriate type of laser, efficient, safe, and regulation-compliant marking can be achieved.

Below are common types of medical laser markers and their characteristics:

1. Fiber Laser

It features high beam quality, making it ideal for fine marking, along with high efficiency and a long lifespan of over 100,000 hours, ensuring low maintenance costs. Additionally, it is suitable for marking metals and certain plastics.

Medical Applications:

- Serial numbers and brand logos on stainless steel surgical instruments (e.g., scissors, forceps).

- Information marking on titanium orthopedic implants (e.g., artificial joints, bone screws).

- Batch numbers and expiration dates on pharmaceutical packaging foils.

2. CO₂ Laser

The CO₂ laser excels in processing non-metallic materials due to its high absorption by organic materials. It is also capable of engraving or creating surface oxidation markings, making it highly versatile for various applications.

Medical Applications:

- Production date marking on glass vials and ampoules.

- Batch marking on plastic IV bags and syringe packaging.

- Marking on silicone or rubber products (e.g., respiratory masks).

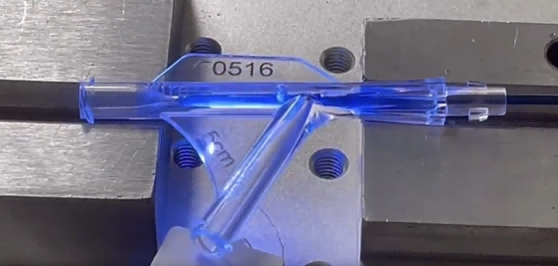

3. Ultraviolet (UV) Laser

The ultraviolet (UV) laser utilizes cold processing technology to minimize heat-affected zones, making it ideal for heat-sensitive materials. Its short wavelength enables ultra-fine marking with micron-level precision.

Medical Applications:

- Micro-marking on polymer catheters and cardiac stents.

- Non-damaging marking on biodegradable materials.

- High-precision QR codes and traceability codes on medical instruments (compliant with UDI standards).

4. Green Laser

Green laser has a high absorption rate for highly reflective materials, such as copper and gold coatings, making it highly effective for precision marking. It is also more suitable than infrared lasers for certain plastics and glass, ensuring superior marking quality on these materials.

Medical Applications:

- Precision marking on electronic medical device housings.

- Clear identification on coated instruments or mirror-like surfaces.

5. Picosecond/Femtosecond Ultrafast Laser

It utilizes ultrafast pulses at the picosecond/femtosecond level, minimizing thermal effects, and is well-suited for processing transparent materials or complex surfaces.

Medical Applications:

- Internal marking on transparent glass or polymer materials (e.g., contact lenses).

- Non-damaging marking on high-value implants (e.g., dental implants).

Finding the Right Medical Laser Marking Machine at Zixu

Zixu provides a comprehensive range of laser marking machines to meet the specific needs of the medical industry. Their machines accommodate various applications, materials, and marking requirements.

Marking Material Types:

- Metals (Titanium, Stainless Steel): Fiber or green laser.

- Plastics/Glass: CO₂ or UV laser.

- Heat-sensitive materials: UV or ultrafast laser.

Marking Requirements:

- Deep engraving: CO₂ or fiber laser.

- High-resolution graphics and text: UV or green laser.

Production Efficiency:

- For high-volume production, fiber or CO₂ lasers are preferred for high-speed marking.

For more product information, please contact our professional customer service for assistance.

Recommended Products