How to Choose the Best Nameplate Laser Marking Machine

Nameplate laser marking machines have become an essential tool for industries that require precise, durable, and high-quality markings on metal, plastic, or other materials. Whether you’re marking serial numbers, logos, or compliance information, choosing the right laser marking machine is critical to achieving optimal results.

What is Nameplate Laser Marking

Nameplate laser marking is a modern method used for creating permanent and accurate markings on nameplates which serve to identify the product, aids in branding, or assist with compliance regulations. The method employs a laser that heats up to vaporize the surface of certain materials such as plastic, metal, or glass thus achieving sharp and inconspicuous markings that are nearly impossible to remove.

Laser marking comes with more benefits than traditional methods such as engraving, ink printing, or stamping.

In contrast to other techniques, laser marking enables one to create detailed logos, fine text as well as intricate designs without losing accuracy. One will also appreciate how legible these markings are over time since they are resistant against wear and corrosion form environmental elements . This technique has quite a few differences with others as it can be applied to stainless steel or aluminiums alloys along with plastics and ceramics. Also worth mentioning is that laser marking does not produce chemical wastage further proving why it non-contact methods makes it eco-friendly.

Industries like automotive, aerospace, electronics and manufacturing with high focus on traceability, documentation and regulatory compliance. Laser marking ensures nameplates for serials, barcodes and logos or even safety information are marked with an unwavering commitment to precision.

Types of Nameplate Laser Marking Machines

When choosing a laser marking machine for nameplates, it’s important to understand the different types of lasers available, as each type has unique advantages depending on the materials you plan to mark and the precision required. Below are the most common types of laser marking machines used for nameplate marking:

CO2 laser marking machines

The CO2 laser marking machines are versatile and popular for engraving non-metal materials like plastics, rubber, glass, and ceramics. Their operation is based on a mixture of gases producing an infrared light beam which is emitted and absorbed by different materials for precise engraving. Though they may not do as well on metals as fiber lasers do, CO2 lasers out-perform in deep detailed engravings on nameplates made of plastics and other non-metals.

Best Suited For: Non-metals including wood plastic glass and rubber.

Key Advantages: Marking almost all non metal materials with great effectiveness during engraving plastics.

UV Laser Marking Machines

Machines that mark with lasers use ultraviolet light to create very precise markings. Because of the shorter wavelength of the UV laser, markings are finer and more detailed while needing less thermal damage. This means the laser is ideal for delicate materials that could be damaged by heat. These machines are used in marking engraving in glass, ceramics and plastics as well as electronics and medical devices fabrication industries where clean and precise work is a must.

Best for: Delicate materials betwen marked with engraved text like glass, plastics, ceramics etc.

Benefits: Better resolution compared to other methods of marking, less exposure to heat damage, adaptable to complex designs including miniaturized texts.

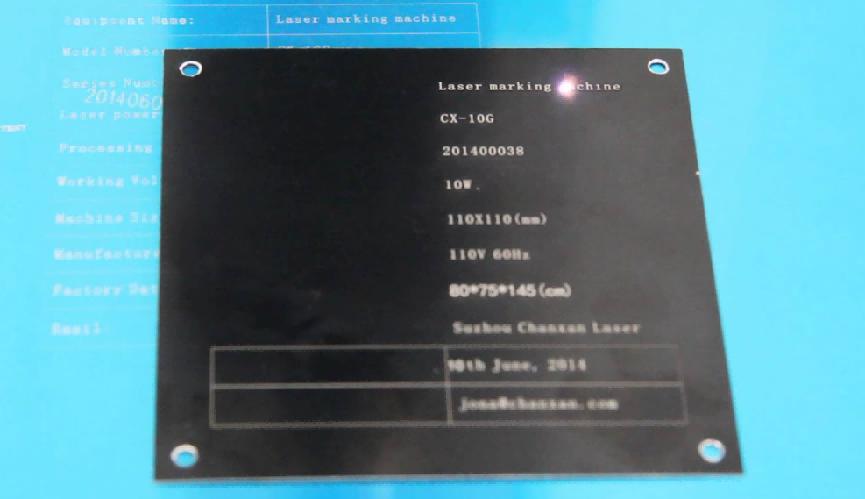

Fiber Laser Marking Machines

For marking metal nameplates, marking fiber laser machines is the most popular option. Such machines employ a solid-state laser delivered via a fiber-optic cable to mark materials like stainless steel, aluminum, titanium, and brass. Fiber lasers have a reputation for being very efficient with engraving, cutting speed, and precision. In addition, they are able to make high contrast permanent marks which is essential in the automotive and aerospace industries where plastic or brittle metals are used.

Best suited: Most metals especially stainless steel targeted aluminum and titanium

Key advantages: Efficiency in speed coupled with low maintenance needs , accuracy precision of work completed during hte process and reduced damage around teh area of heat exposure.

YAG Laser Marking Machines

YAG lasers use solid state technology with a crystal to produce the laser beam. Although not as prevalent in today’s industry compared to fiber or CO2 lasers, YAG lasers still serve their purpose as engravers on plastics and metals. These lasers are best for deep engravings and applications that need a compromise between engraving speed and depth. Regardless, many industries have shifted to using fiber lasers due to their better productivity and lower maintenance requirements.

Perfect for: Engraving Plastics and metals marked deeply.

Best features:

Multifunctional,

Pays attention to detail,

Deep marks may be produced,

Devoted berary more into improving efficiency than other laser systems.

What to Consider When Choosing a Nameplate Laser Marking Machine

When selecting a nameplate laser marking machine, there are several key factors that should guide your decision. Below is a helpful breakdown of these factors:

| Factor | Considerations |

| Material Compatibility | – Choose a machine compatible with the materials you plan to mark (metal, plastic, etc.). |

| – Fiber lasers: Best for metals (steel, aluminum, brass). | |

| – CO2 lasers: Ideal for plastics and some coated metals. | |

| – UV lasers: Great for delicate materials (plastics, ceramics). | |

| Marking Speed & Efficiency | – Faster speeds lead to higher throughput. |

| – Consider the balance between speed and marking quality (too fast can affect detail). | |

| Laser Power | – Higher power (50W-100W) for thick metals and deep engravings. |

| – Lower power (20W-30W) for fine detail and light markings on thinner materials. | |

| Precision & Resolution | – Choose machines with high precision (low micron level) for detailed designs. |

| – Important for small or intricate nameplates (e.g., logos, serial numbers). | |

| Ease of Use & Software Integration | – Look for user-friendly interfaces and software integration with your design tools. |

| – Features like auto-scaling and variable text fonts enhance versatility. | |

| Maintenance & Durability | – Opt for machines that require minimal maintenance and offer reliable performance. |

| – Ensure availability of replacement parts and service support. | |

| Budget | – Determine your budget, considering both initial costs and long-term maintenance/consumable costs. |

| – Balance performance with cost efficiency. |

This structure allows the key factors to be quickly referenced, making it easier to compare and prioritize based on specific needs.

Tips for Testing and Evaluating Machines

As with any piece of equipment, a nameplate laser marking machine must undergo testing and evaluation to ensure that it fulfills requirements and expectations. Here are some suggestions that could assist you at this stage:

- Inspect Marking Quality: Evaluate the mark’s quality on the sample by checking for clarity, contrast, and overall sculptured precision. Gaze into minute details like sharp edges if your nameplates are intricate.

- Evaluate The Machine Software And User Interface: Assess whether the software user interface (UI) is easy to use (intuitive). Ensure essential features such as design modification tools, barcode creation capabilities, as well as compatibility with common file types DXF, BMP or even AI are present. Streamlined software interfaces significantly improve workflow productivity.

- Assess Speed And Efficiency: Measure how long the machine takes marking specific tasks in order to gauge speed at which each operation is done. For customers with high volumes of work through-put speed becomes imperative for consideration.4. Assess Construction and Rigidity: Examine the machinery s parts to evaluate construction as well as its build quality. A machine that is solid and well built stands a better chance of providing consistent performance as well as having longevity.

- Review After Sales Services: While choosing nameplate laser marking machine, it is also very important to look at the supplier’s after sales support e.g. customer care, technical services, warranty and other similar matters. An effective system on after-sales services can be helpful when problems arise later.

These considerations will guide you in making the appropriate selection of the equipment with optimal performance, accuracy, best reliability features, and high precision which meets the requirements of your business operation. To ensure that your investment serves you well both in the near term and in the long-term, make sure you rigorously test all these options before deciding.

Your selection of laser marking apparatus for nameplates should take into account the materials you are working with, as well as the specificity of the marking. For metal nameplates, fiber lasers tend to be the most efficient and accurate. On the other hand, CO2 lasers are consummate in marking non-metal materials such as plastics. If precision is paramount for soft materials, then UV lasers would suit best; whilst YAG lasers are preferred best for deep intricate marks both on metals and plastics.YAG does well too on both with moderate precision cuts. With adequate knowledge of these technologies , it becomes easier to choose the right machine for any task at hand.

Let us know if you need assistance in nameplate marking or have any other inquiries our teams would gladly assist you with!

Recommended Products