Glass Laser Engraving Machine: A Precision and Creative Tool

Glass has long been an exquisite medium for creative and functional designs, yet traditional engraving methods often lack precision and detail. That is where laser engraving machines come into their own; these powerful tools enable intricate yet permanent designs without risk of cracking or chipping which comes with hand engraving methods.

No matter if you are an artist creating beautiful glass art or an industrial manufacturer marking industrial glass components, glass laser engraving machines can streamline your workflow and save you time and effort. Let’s examine their functioning, capabilities and how best to select one suited to your requirements.

What is a Glass Laser Engraving Machine?

Glass laser engraving machines are high-tech tools that use laser beams to permanently and intricately decorate glass surfaces with beautiful designs. These machines can create everything from delicate floral patterns to corporate logos with perfect accuracy every time.

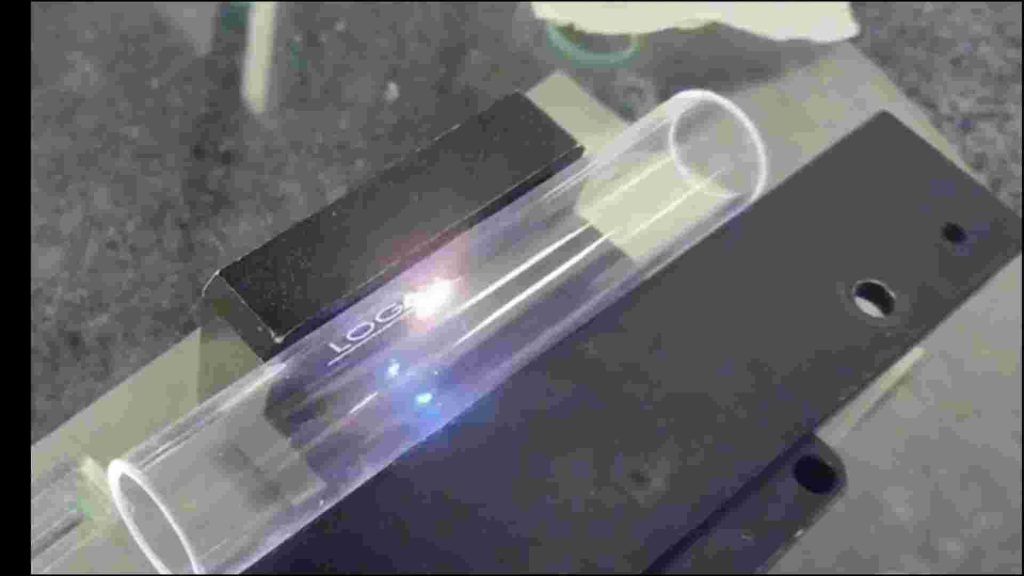

Laser machines stand out from other engraving methods thanks to their non-contact approach. Instead of relying on physical bits or sandblasting for engraving purposes, the laser creates microscopic fractures in glass surfaces using controlled heat, meaning no cracked edges or uneven pressure! You get consistent and clean results every time.

Laser engravers come in various sizes, from desktop models ideal for gift shops to industrial-grade units used for mass production. Laser engravers transform ordinary glassware into something truly extraordinary, from personalizing wedding glasses, creating architectural signage, or marking lab equipment – and once you master its surprisingly user-friendly software, you can replicate designs identically each time!

How Does a Glass Laser Engraving Machine Work?

Laser engraving may look like magic, but the science behind it is relatively straightforward. Here’s how these remarkable machines transform plain glass into personalized works of art:

Starting the process begins with your digital design – be it an intricate pattern, company logo, or message created using CorelDRAW or Adobe Illustrator graphic software. From here, the machine’s computer translates this design into specific movement instructions for the laser head to create it.

When the engraving starts, the machine focuses an intense beam of light onto the glass surface. Instead of physically scratching away material through traditional engraving tools, laser engraving works by creating controlled microfractures in glass through rapid heating and cooling processes, leading to that distinctive “frosted look” without actual material removal.

Success lies within three adjustable settings:

- Power determines how deeply the laser penetrates

- Speed controls how quickly the laser moves

- Frequency affects the texture of the engraving

Clear glass typically requires lower power settings (10-30% of maximum) at higher speeds to achieve an appealing, white frosted effect; thicker or tinted glasses may necessitate adjustment to these parameters.

An additional yet useful method for engraving is placing a damp paper towel over the engraving area, as this helps dissipate heat to reduce thermal stress cracks while often improving clarity in finished designs. After engraving is complete, simply wipe down to eliminate any remnants and reveal crisp permanent designs!

Laser engraving stands apart due to its exceptional precision, capable of reproducing even complex designs with perfect consistency – something virtually impossible by hand.

Common Application of Glass Laser Engraving Machines

Glass laser engraving isn’t just fancy tech; it solves real-life issues for businesses and creatives. Here is where these machines truly demonstrate their worth:

Give Gifts that Feel Special

Generic gifts from big stores often look mass-produced. A laser engraver changes that, creating personalized keepsakes with meaningful customization that feel truly personal for each guest at a wedding or retirement with deep-etched portraits that won’t fade like ink prints do. Boutique shops use these machines to transform 5 glassware pieces into 50 keepsakes by simply adding meaningful customization, from delicate cursive fonts to detailed silhouettes – this precision of laser technology manages it all effortlessly!

Awards and Trophies

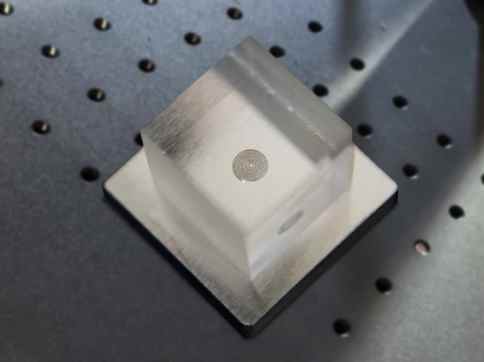

Plastic plaques adorned with metal plates signal participation awards, while laser-etched crystal awards make lasting statements in offices for decades to come. When the laser creates 3D effects within thick glass (company logos appear to float while text has shadowy depth that surface etching cannot replicate), clients (particularly corporate ones) often pay a premium price for unique gifts that do not look manufactured. Trophy shops charge premium prices because clients will often prefer something unique over something manufactured at a trophy factory.

High-End Decor That Sells Itself

Home stagers understand this trick well: A plain mirror becomes an expensive “designer piece” by adding delicate laser-etched vines in its corners and restaurant install them for custom light diffusion purposes. Furthermore, unlike vinyl decals that peel or paint that wears off over time, laser markings remain permanent – an advantage interior designers appreciate because these pieces can withstand commercial spaces while remaining elegant enough for luxury homes.

Branding That Stays “We’re Professional”

Step inside any upscale hotel or law firm–their glass doors feature nearly invisible logos that only become apparent when illuminated from below by light at just the right angle, thanks to laser frosting. Bars often laser etch their logos onto pint glasses, withstanding many dishwasher cycles; and tech companies use ultrafine laser markings on device components as traceability measures – these details differentiate premium brands from average ones.

Laser engraving does what human hands cannot: perfect consistency each time, from one-off gifts to production runs; its unmistakable high-end finish customers are willing to pay extra for. From Etsy shops to corporate clients, glass laser engraving offers real profit potential.

Choosing the Right Glass Laser Engraving Machine

Selecting an ideal glass laser engraving machine depends upon several essential criteria, ensuring it can meet both creative and technical demands.

Laser Type and Power

CO2 lasers typically range between 30W to 100W; their ability to create fine marks without cracking glass makes them the go-to laser choice for glass engraving. For 3D glass engraving applications however, higher wattages (60W or above) often prove preferable as this allows deeper layering effects and deeper layering effects than their CO2 counterparts can achieve. Fiber lasers may also be utilized, though generally these work better at surface marking rather than creating deep or 3D effects.

There is a wide variety of glass products, so we don’t recommend standard UV, CO2, or MOPA fiber laser machines for everything. It is best to use a customized solution for your specific needs: glass composition, the work environment, the production speed, and the target quality and budget.

Work Area and Precision

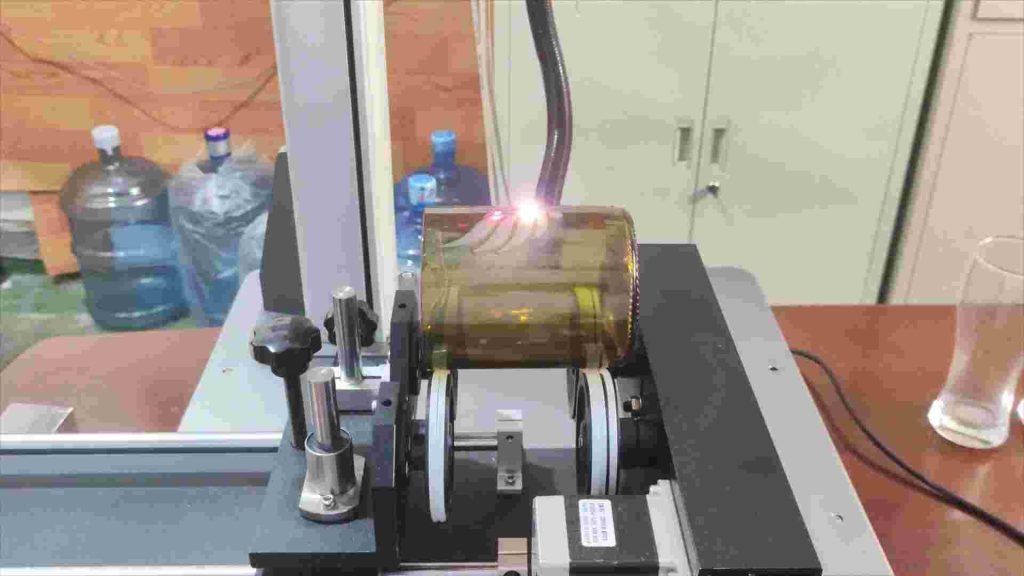

The machine bed size must suit its intended projects: larger surfaces may be necessary when engraving architectural glass or large awards; in contrast, compact machines are appropriate for engraving small decorative items or 3D engraving of small parts such as buttons. A high-precision Z-axis can accurately control depth variations during 3D engraving while machines with rotating attachments such as bottles or vases offer added advantages when engraving cylindrical glass objects like bottles and vases.

Software Compatibility

A user-friendly interface and advanced design capabilities are crucial when working in 3D. When selecting machines for 3D work, ensure they support industry standard formats (AI, DXF and STL) as well as depth mapping features and offer depth-mapping features. Some systems even come equipped with proprietary software designed specifically to convert 2D designs to volumetric engravings quickly and effortlessly.

Tips for Optimal 3D Glass Laser Engraving

Producing stunning 3D engravings requires more than the right equipment; it also involves careful planning, materials selection, and technical tricks to produce eye-catching 3D glass laser engraving projects with spectacular results. Here are a few essential guidelines to help your 3D glass laser engraving efforts produce striking designs:

Selecting an Appropriate Glass Type

Not all glasses can provide optimal clarity, detail, and durability when laser engraving 3D designs. For optimal clarity, detail, and longevity in 3D engraving projects, consider:

- Lead Crystal: Due to its superior clarity and density, lead crystal is ideal for crafting intricate 3D designs with fine details at high resolutions. Reacting favorably with laser energy and providing great depth perception.

- Optic Glass: Optically clear Glass is highly esteemed for its purity and lack of internal defects, making it perfect for precision 3D engraving and fine art pieces as well as awards.

Avoid standard soda-lime glass for 3D engraving as this material could contain impurities that lead to unexpected outcomes.

Customise Software Settings to Achieve a 3D Effect

Your engraving software plays a pivotal role in how laser light interacts with glass surfaces and how 3D effects appear on glass panels. For optimal 3D results:

- Adjust Layering: Utilize vector files or grayscale 3D models with layers to tell the laser where to engrave deeper or lighter, increasing or decreasing laser pulses depending on where engraving takes place, creating deeper effects with increased pulses or maintaining shallow surfaces with reduced pulses.

- Control Laser Power and Speed: Lower speeds and higher power settings generally increase depth; however, striking an appropriate balance is critical; excessive laser light could crack glass surfaces if left on too long.

- Use 3D Design Software: Software like 3ds Max or Blender as well as specific laser engraving programs like LaserWorks or RDWorks, enable precise control over multilayered engravings.

Try running test runs on scrap pieces to refine these settings before beginning engraving your final design.

Post-Processing for an Outstanding Finish

After engraving has taken place, some post-processing steps may help your design stand out even more:

- Cleaning: Use a soft cloth and alcohol-based cleaner to wipe away any leftover debris or glass particles, while being wary of materials that might scratch or mar the surface.

- Polishing: To add shine, polish glass using either a microfiber cloth or glass polishing compound in order to increase transparency and eliminate haze.

- Optional Coatings: In some instances, applying a clear protective coating may help preserve engraving while giving it a glossy sheen.

Proper post-processing enhances not only visual appeal but also extends the longevity and clarity of any engraved design.

With quality materials, accurate software settings, and thoughtful post-processing steps in place, 3D glass laser engravings can achieve professional-grade details and depth that truly stand out.

Final Thought

A glass laser engraving machine is a powerful tool for businesses and hobbyists looking to create high-quality, customized glass products. With precision, speed, and versatility, it opens up endless creative and commercial opportunities. By choosing the right machine and following best practices, you can achieve professional-grade engravings that stand out. Whether for branding, personalization, or artistic expression, investing in a glass laser engraving machine can elevate your craftsmanship to the next level.

Want to know more about glass laser engraving machine? Contact Zixu now!

Recommended Products