FIVE Common Dot Peen Marking Mistakes and How to Avoid Them

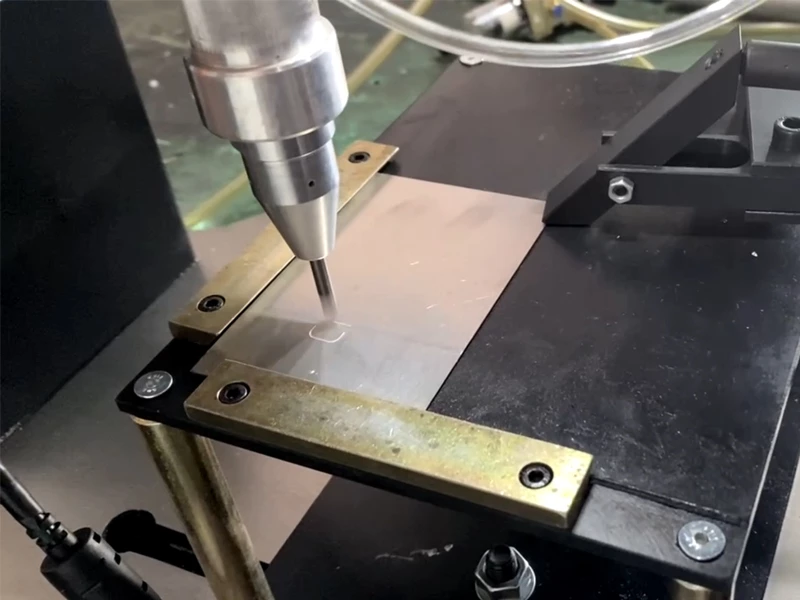

Dot peen marking is one of the most common methods for identifying and tracking all types of industrial metal materials and products. However, even with a reliable machine, mistakes can still occur—leading to illegible marks, wasted materials, or costly rework. To achieve optimal results and efficiency, you need the right machine, proper setup, and ongoing maintenance. Our reliable dot peen marking machines are designed to engrave permanent markings on hard metals and plastics. We source all our core components from world-leading brands to ensure accurate, smooth, and efficient marking. Many Fortune 500 manufacturers favor our machines. By upgrading your marking equipment and learning how to avoid common dot peen marking mistakes, your company can dramatically boost productivity and consistency.

Importance of Avoiding Dot Peen Errors

Dot peen marking requires selecting the appropriate model, marking needle, and control software settings according to the hardness of the metal being marked. Since dot peen marking leaves a permanent mark of a certain depth, if the marking is incorrect, the entire workpiece must be reworked, resurfaced, or scrapped.

Automated dot peen marking is even more critical because a mistake may result in an entire batch of products being scrapped or reworked, which increases labor, time, and costs, thereby reducing the profits of the manufacturing enterprise.

5 Commonly Dot Peen Mistakes and How to Avoid Them

1. Buying and Using the Wrong Machine

There are many dot peen marking machine manufacturers in Europe, the United States, and China. Each manufacturer and its products have unique characteristics. If your machine does not meet your needs, you may need to upgrade the controller to support the necessary features, or replace the entire system.

- What is your priority: cost, value, or high-tech features? Consider your needs regarding quality, efficiency, and overall investment before making a decision. Then, contact us or another brand for a quote.

- Many customers choose dot peen marking because they need to mark at a specific depth. In this case, an integrated system is not recommended because prolonged use of higher forces may cause vibrations that exceed design expectations, which could damage the control motherboard. Additionally, the split system controller can be more easily upgraded or replaced to accommodate future needs.

- Customers in different countries have different expectations regarding system prices and efficiency. There are well-established companies in the market that provide a complete line of solutions to customers, while others manufacture and sell standardized models to reduce costs and increase capital turnover efficiency. The level of service, training, and technical support that you will receive from different marking machine manufacturers for the same amount of money varies from country to country, so please take the time to investigate.

- Many brands no longer develop and produce their own dot peen marking machines, especially since laser systems have become more popular. Today, we customize and manufacture dot peen marking machines and needles for dozens of brands worldwide. We account for approximately one-third of the global production capacity of marking needles.

- Price competition in the dot peen marking machine market has increased due to the 2020 epidemic and the deterioration of U.S.-China relations. To remain competitive, some manufacturers have lowered the cost and quality of unobtrusive components, such as guide rails and handles. In 2024, dozens of our customers purchased low-quality marking machines that broke shortly after purchase. Then, they switched to our dot peen marking machines.

2. Choose a Dot Peen Marking Machine When a Scribing Marker is Needed

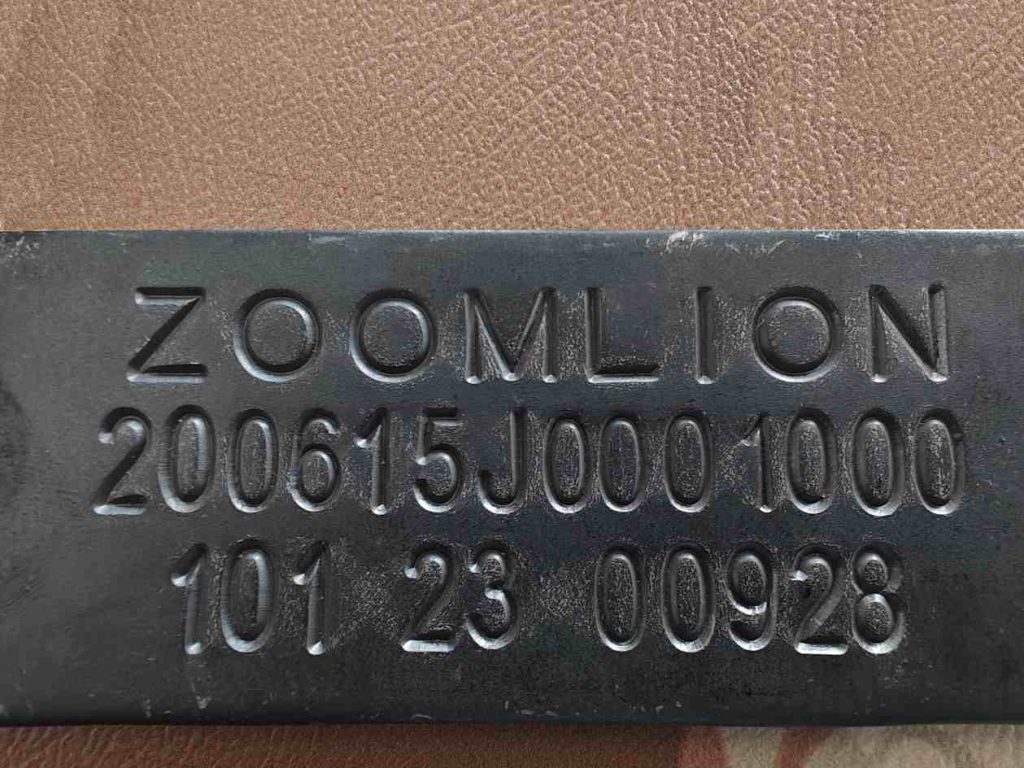

Both dot peen and scribe use compressed air to drive a needle tip into a metal or other hard surface, leaving a permanent mark. The difference is that dot peen uses high-frequency impact to create dots, while scribe is similar to writing. Dot peen marking is typically used for industrial identification and traceability, while engraving is used for branding and personalization on the exterior of products.

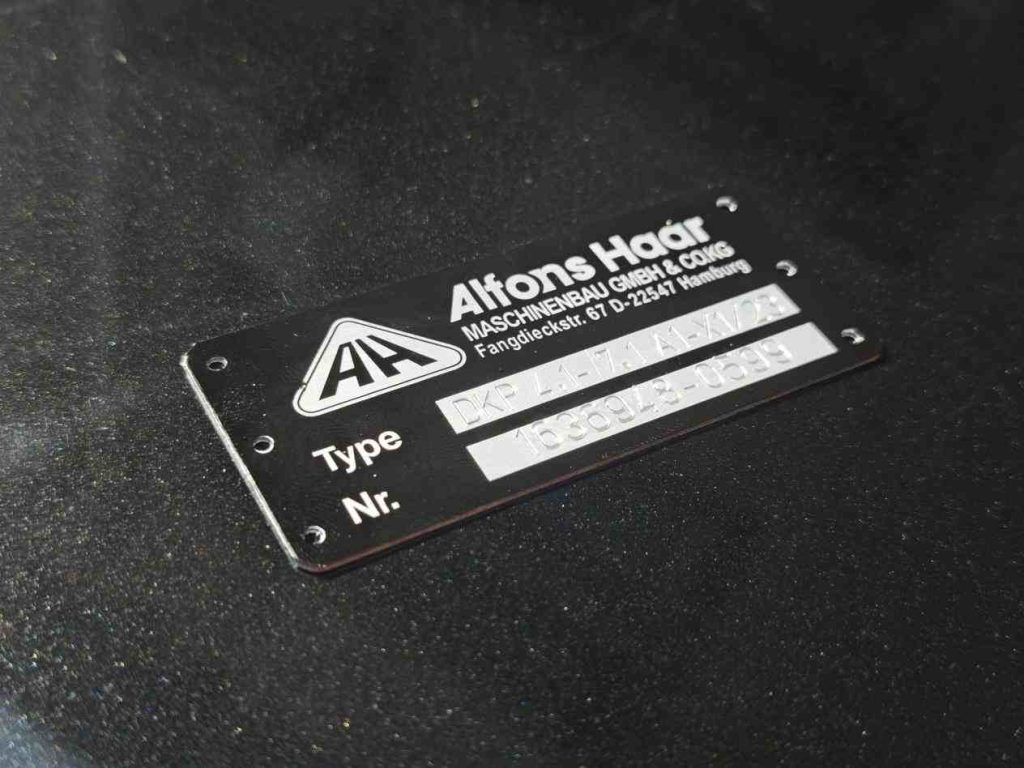

However, there are different segments for each type of product: cheap and high-end. The cost of an engraving system is higher, and the marking effect is unique. Therefore, it is also used for some high-end brand identification and traceability marking. One example is the use of an engraving machine for vehicle identification number (VIN) marking on cars such as Mercedes Benz, Jaguar Land Rover, Porsche, and Ferrari.

We design and produce scribe marking machine that can mark surfaces as smooth as a mirror. According to our measurements, the flatness is equivalent to a 5,000–8,000 mesh polish. This ensures that high-end brands meet their most subtle requirements.

3. Lack of Proper Maintenance

Neglecting regular maintenance can lead to reduced marking accuracy, equipment damage, and costly downtime.

- Regularly replace marking needle: this applies to standard and special process quenching hardened or diamond-tipped needles. Otherwise, the tip may chip or break during use, and interior damage is not visible to the naked eye.

- Regularly Lubrication and Calibration: dot peen marking machines use X-Y axis rails with motorized movement. To ensure accurate and consistent marking, it is essential to regularly lubricate and calibrate the motors and guides.

- Controller Calibration: although you can easily adjust the size and position of the marking content on the touchscreen, if the displayed content does not correspond to the signals received by the marking machine, the marking will be distorted or shifted. Periodically calibrating the controller’s display in the software is also necessary.

4. Selecting the Right Marking Needle

Selecting the right marking needle is critical to achieving clear, consistent, and durable results with dot peen marking machines. Different materials and applications require different needle types—such as standard steel, hardened, or diamond-tipped needles. Using the wrong needle can lead to poor mark quality, excessive wear, tip breakage, or even internal damage to the marking head. Inconsistent depth, distorted patterns, or incomplete characters are common signs of an unsuitable needle. Ultimately, improper needle selection increases maintenance needs and reduces overall marking efficiency and product quality.

Our standard tungsten carbide marking needles (95 HRA) are suitable for engraving steel up to 60 HRC. For harder materials like 65 HRC high-carbon steel, hardened or drilled needles are recommended to extend tool life and ensure reliable marking. For high-temperature surfaces (300–900°C) such as steel coils or forged wheels, we offer specially designed heat-resistant needles.

5. Choosing the Right Control System

Different control systems have different functions and performance capabilities. For example, although the Thorx-6 software theoretically supports font installation, errors occur when importing fonts provided by automobile manufacturers. Therefore, we typically recommend the compact, all-in-one Kingmark-3 machine for VIN dot peen marking. For a split system configuration, we recommend the Thorx-7.

You can check the software features in our product page: https://www.cnmarking.com/handhold-pneumatic-dot-peen-marking-machine or ask for an advice.

Find the Best for You from Zixu Marking

As one of the world’s largest producers and sellers of pneumatic marking machines and accessories, Zixu has robust research and development capabilities and the ability to fulfill custom orders. We understand the challenges that manufacturers face and offer solutions tailored to different materials, environments, and production needs. Our machines are trusted by many Fortune 500 companies for their durability, efficiency, and ease of use.

Avoiding dot peen marking mistakes starts with the right equipment and support. Contact Zixu Marking today to upgrade your marking process and enhance your operational efficiency.

Recommended Products