Best Practices for Using a Portable VIN Number Marking Machine

VINs (Vehicle Identification Numbers) are vital tools for tracking vehicles, meeting legal compliance requirements and avoiding fraud. A portable VIN number marking machine provides a useful method of engraving or stamping VINs onto vehicles, parts or machinery with precision and efficiency.

Users seeking to maximize the benefits of VIN marking devices must follow best practices to ensure durability, compliance and readability. This article highlights the significance of proper VIN marking as well as recommended practices when using portable VIN marking machines; common mistakes to avoid and tips for selecting an ideal machine are all discussed here.

What is Portable VIN Number Marking Machine

A portable VIN number marking machine is a small, handheld, or transportable equipment used to engrave, stamp, or etch car Identification Numbers (VINs) on metal surfaces such as car frames, engine blocks, and parts. These devices offer a permanent, tamper-resistant marking technology that meets legal and industry standards.

Portable VIN markers are widely used by:

- Automakers & Dealerships – For marking new vehicles or replacement parts.

- Law Enforcement & Government Agencies – To combat theft and verify vehicle authenticity.

- Insurance & Inspection Services – For accurate vehicle identification and record-keeping.

- Scrap Yards & Recyclers – To track and authenticate salvaged parts.

Common types include:

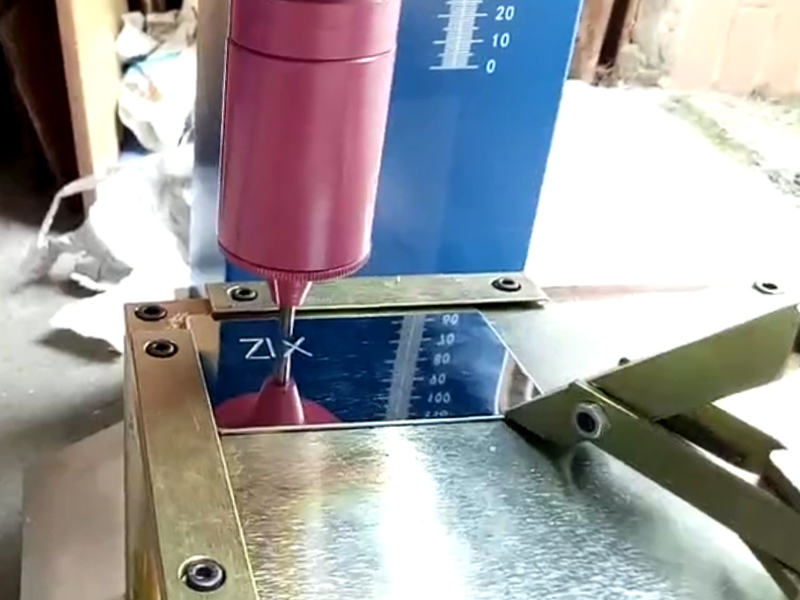

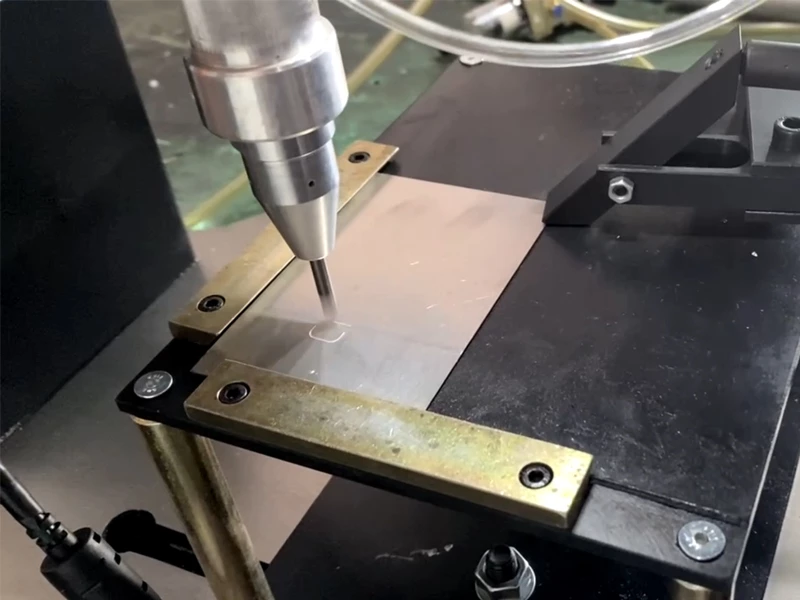

- Dot Peen Markers – Use a pneumatic or electric pin to make long-lasting dot-matrix engravings.

- Laser Markers – Provide high-precision, non-contact etching for sensitive components.

- Stamping Machines – Use physical force to emboss VINs, creating a permanent, deep impression.

These machines keep VINs legible, fraud-resistant, and compatible with rules, making them critical for vehicle security and traceability.

Why Following Best Practices Matters

The proper use of a portable VIN number stamping machine is crucial for legal compliance, security, and operational efficiency.

- Government rules frequently require accurate VIN placement and reading; noncompliance might result in fines, refused registrations, or legal difficulties.

- Proper branding also prevents fraud and theft. A neatly engraved, tamper-resistant VIN makes it more difficult for criminals to modify or counterfeit car identities. This is especially crucial for law enforcement, insurance companies, and used automobile dealers that rely on proper identification.

- Furthermore, sturdy and clear markers enable long-term traceability. A well-marked VIN makes monitoring and resolving disputes easier, whether for recalls, warranty claims, or ownership transfers. Poorly marked codes can fade, corrode, or become unreadable, requiring costly rework.

- Finally, following best practices extends the machine’s lifespan and maintains marking consistency. Proper maintenance, calibration, and technique prevent errors, reduce wear on equipment, and ensure reliable performance.

By adhering to industry standards, businesses can avoid penalties, enhance security, and streamline operations—making best practices essential for anyone using a portable VIN marking machine.

Best Practices for Using a Portable VIN Number Marking Machine

To achieve precise, durable, and professional VIN markings, adopt these critical best practices:

1. Properly prepare the surface

Prior to marking, always carefully clean the metal surface. Remove any dirt, rust, oil, or paint that could disrupt the marking process. A clean surface allows the marking head to penetrate more deeply and reduces irregularities. Surface preparation not only enhances marking quality but also increases machine life by lowering resistance during the engraving process.

2. Select the Correct Machine Settings

Every material and thickness requires specific settings for optimal marking. Adjust parameters such as marking depth, speed, and force based on the type of metal and desired finish. Using too much force can damage thin surfaces, while insufficient settings can result in shallow, hard-to-read VINs. Always test settings on a scrap piece of the same material before marking the final surface.

3. Ensure Proper Machine Positioning and Stability

Hold the marking machine steady and perpendicular to the surface during operation. If the machine moves or tilts during marking, it can cause uneven, slanted, or broken characters. For consistent results, use fixtures or supports when possible, especially on curved or awkward surfaces. Some machines come with optional magnetic bases or stands to improve stability.

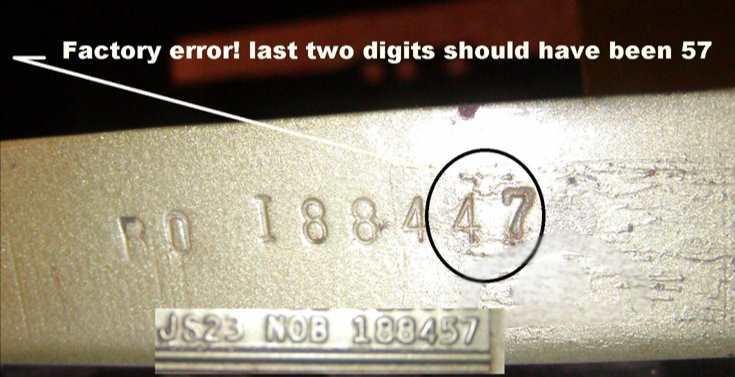

4. Double-Check VIN Information Before Marking

Verifying the VIN before you start is crucial. A mistake in the VIN sequence can lead to serious legal and administrative problems. Double-check all characters for accuracy and layout. If your machine has a preview function, use it to confirm placement and spacing before finalizing the mark.

5. Perform Regular Maintenance on the Marking Machine

To keep your portable VIN marking machine working at peak performance, routine maintenance is essential. Clean the marking head after each use, check for wear on key components, and follow the manufacturer’s recommendations for lubrication or part replacement. Regular maintenance minimizes downtime, extends machine life, and ensures consistently high-quality results.

By following these five best practices, you can maximize the effectiveness of your VIN marking process while protecting both your equipment and your reputation.

Common Mistakes to Avoid When Marking VINs

Even experienced operators can make errors when marking VINs if they aren’t careful. Avoiding these common mistakes will help ensure your markings are clear, compliant, and long-lasting:

- Neglecting Surface Preparation: Failing to properly clean and prepare the surface before marking can lead to poor adhesion and inconsistent results. Dirt, oil, and rust can interfere with the marking process, making the VIN harder to read and less durable over time. Always ensure the marking area is clean, dry, and free of contaminants.

- Using Incorrect Machine Settings: Applying the wrong settings — such as excessive force, incorrect depth, or inappropriate speed — can cause serious problems. Too much force may damage the material or deform thin plates, while too little force can result in shallow, illegible marks. Always adjust settings based on material type and thickness and perform a test marking beforehand.

- Poor Machine Handling and Stability: Holding the marking machine at an inconsistent angle or moving it during operation can create uneven, distorted characters. Stability is key to achieving a professional, readable VIN mark. Use supports, fixtures, or magnetic bases if needed to keep the machine steady throughout the process.

- Failing to Verify VIN Information: Marking the wrong VIN is a costly and time-consuming mistake. Whether it’s a simple typo or a misplaced character, errors can lead to compliance violations and the need for rework. Always double-check the VIN sequence against official records before starting any marking job.

- Skipping Regular Machine Maintenance: Overlooking routine maintenance can lead to machine malfunctions, inconsistent marking quality, and costly repairs. Components such as the marking pin or laser head can wear down over time. Regular cleaning, inspection, and timely replacement of parts are essential to keep the equipment running smoothly.

By being aware of these common mistakes and taking steps to avoid them, you can ensure that every VIN you mark meets the highest standards for quality, accuracy, and durability.

Tips for Choosing the Right Portable VIN Marking Machine

When selecting a portable VIN marking machine, consider these key factors to ensure it meets your needs:

- Technology: Choose between dot peen or laser marking technologies. Dot peen is ideal for marking metals, providing durable, high-quality results. Laser marking is precise and works well for detailed designs but may be more expensive.

- Portability: If you plan to use the machine in various locations, look for a lightweight, compact model that’s easy to transport. Some machines offer rechargeable batteries for more flexibility.

- Ease of Use: Opt for a machine with a user-friendly interface and ergonomic design to reduce operator fatigue. Look for intuitive controls that minimize the learning curve.

- Durability: Ensure the machine is built to last, especially if used frequently or in tough environments. A robust, well-constructed machine can withstand wear and tear.

- Support and Service: Choose a machine from a reputable brand with good customer support, including training resources, warranty, and repair services.

A portable VIN number stamping machine is critical for legal compliance, security, and traceability in the automotive and manufacturing sectors. Users may ensure clear, durable, and compliance markings by implementing best practices such as adequate surface preparation, accurate VIN entry, and machine maintenance.

Avoid typical blunders, such as wrong depth or poor positioning, and select a machine that meets your operational requirements. With the appropriate strategy, portable VIN marking machines can provide a long-term, fraud-resistant solution for vehicle and part identification.

Need more information about VIN number marking machines? Feel free to contact us.

Recommended Products