All About Glass Laser Etching, Marking, Engraving & More

In glass laser etching, sandblasting, perforating, or cutting, the process essentially involves using a high-energy laser beam to interact with the glass, causing ablation, which results in melting, vaporization, or reaching a critical point, thereby achieving material removal. Therefore, the glass cannot use the laser in the strict sense of “marking,” but rather through laser etching, which ablates a part of the surface material, creating a similar effect to the traditional sandblasting process and is therefore also known as laser sandblasting.

Principles and Mechanisms of Glass Laser Ablation

The principles and mechanisms of laser ablation of glass depend on the laser’s wavelength and power density. I will briefly explain these principles and mechanisms below to help you understand the detailed process and machine selection in the following content.

Main Glass Laser Ablation Mechanisms:

- Thermal ablation: This method involves localized heating that melts or vaporizes the glass material. Then, vapor expansion carries away some of the material;

- Optical ablation: Material is removed by breaking the chemical bonds between atoms directly using extremely high peak power;

- Plasma-assisted ablation (LIPAA): A laser induces plasma on the glass surface. The plasma then interacts with the glass, generating shock waves and cavitation bubbles that facilitate further material removal.

The following article describes how the ablation mechanism of the laser and the glass affect the difficulty of laser etching, punching, and cutting glass. This will help you understand these processes in depth and make the right choices when purchasing the laser machine for those process.

Logo or Other Personalized Information Printing

We typically recommend using UV or MOPA fiber laser marking machines for etching glass, especially for logos or personalized designs, and use UV or green lasers for subsurface etching. These machines have several advantages over CO2 laser engraving machines for DIY projects. We will elaborate on these below:

High Precision

Various types of lasers can etch glass without making contact, which results in a much higher overall etching efficiency than traditional methods like sandblasting. However, there are still differences among these lasers.

- The reaction between the laser and the glass relies mainly on heat ablation. However, glass is sensitive to the thermal effect and prone to chipping. Consequently, conventional CO2 lasers often require the glass to be submerged by water before etching. UV lasers have a lower thermal effect and typically do not require additional treatment, making them ideal for precise etching and marking on glass surfaces.

- Nevertheless, producing high power and energy density with UV laser systems is costly, so MOPA fiber lasers are often used for large-format glass sandblast etching, and green lasers are often used for subsurface engraving to achieve high efficiency. Among them, the green laser diode can achieve higher transient energy compared with the solid-state laser green fiber laser, the formation of vacuoles in glass 3D subsurface engraving is more efficient, and is the mainstream laser for such applications.

- In addition, nanosecond MOPA fiber lasers and even faster picosecond infrared, green and ultraviolet lasers can achieve very high instantaneous energies and reduce thermal effects by decreasing the contact time between the laser and the glass, resulting in less chipping and significantly higher yields.

These lasers are used in industries that require precision cutting, drilling, and scribing of glass, such as TV, computer, and cell phone displays, automotive windows and lights, photovoltaic modules with glass substrates, and precision optical glass components.

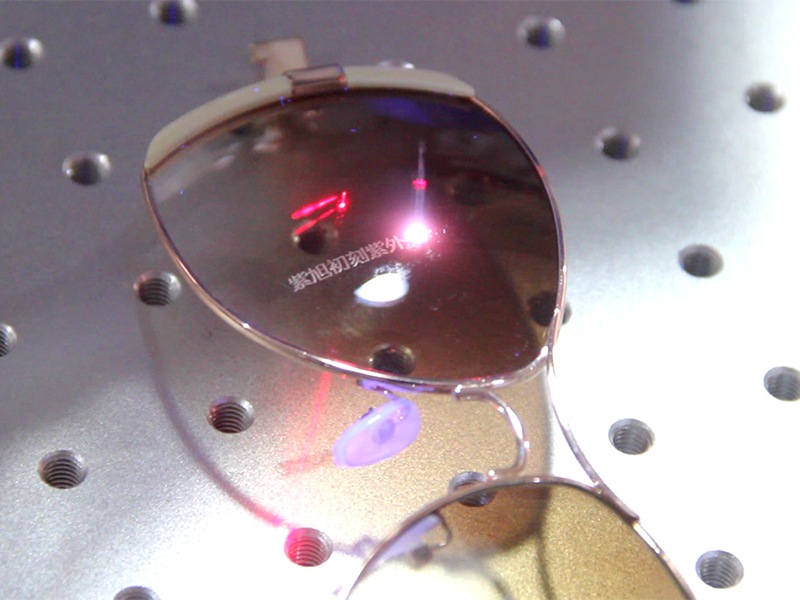

High Value Niche Marketing

Whether it’s using conventional UV laser marking machines to etch 360-degree logos and personalized appearances on small glass parts such as wine bottles, wine glasses, or perfume bottles, or using nanosecond MOPA fiber laser marking machines for products such as smart mirrors and abyssal mirrors, or using ultra-fast picosecond laser cutters for the production of precision glass components, we have the proven technology to help these segments. We provide mature technological solutions to help customers in these industries seize business opportunities and reap substantial returns far beyond their investment.

Automation possibility

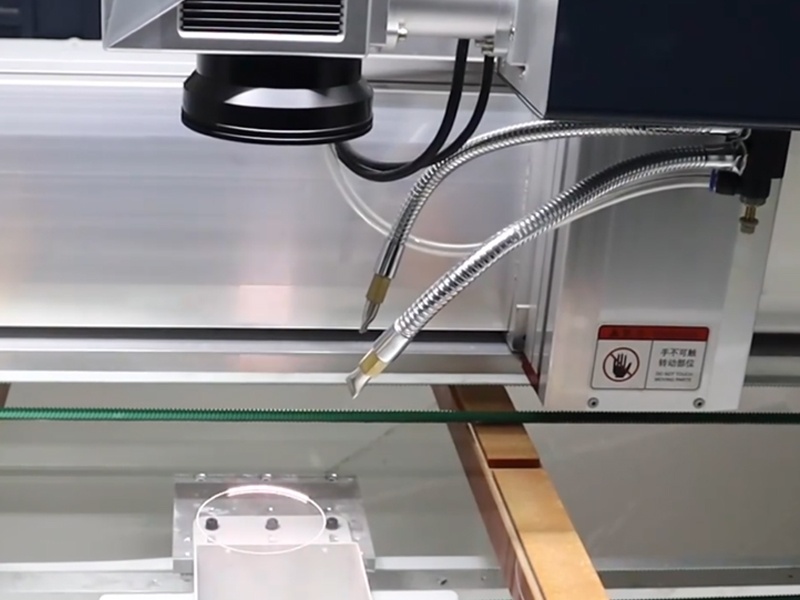

Although no physical contact is required for laser etching glass, the laser focus still needs to be precisely controlled. For instance, using a 10W or higher dynamic rotary laser marker to etch 360-degree content on a glass can achieve efficiencies several times greater than a 5W model. However, the increased energy density is also more likely to cause thermal stress, resulting in cracking or even an explosion. Therefore, when designing an automated laser process for glass, it is crucial to precisely match the loading and unloading, position, focal length, and laser parameters. We usually recommend that our customers use a relatively basic model for etching and then design their own high-efficiency automation solution based on the actual loading and unloading operations. They should also purchase and customize the corresponding components and tooling for deployment.

How to Choose the Right Laser Machine for Your Etching Needs

Glass is used in a large number of applications in a variety of industries, and different users have different needs for processing these glass products, so choosing the right type and configuration of machine to achieve the best balance of cost, quality, and efficiency for you specific need. Right now, we’ve got a bunch of experience with laser etching on some common glass products. Let’s take a look at some examples.

Drinkware Glassware

Globally, more than 10 billion pieces of glassware are produced and sold each year. Laser etching is the most common method for marking glassware with brand logos, manufacturer information, and other personalized content. For large quantities of branding and other content, we recommend using a flying in line rack style UV laser marking machine for efficient etching. For 360-degree patterns and other large circumferential surfaces, we recommend using the dynamic rotary marking function of a UV laser marking machine, which operates with 3D scanning galvos to improve surface quality for complex shaped glass drinkware.

Glass containers

Glass containers are more productive than drinking vessels, and are used in a wide range of applications, from glass jars for spices and beverages in everyday life to glass containers for medical and biological applications. For these glass containers, there is a wide range of options for laser etching.

- For example, for the shelf life of beverages, the flying in line rack type CO2 laser marking machine is usually used, its 10.6μm wavelength thermal ablation efficiency is high, and the marking of single line fonts and graphics without filling to meet the visibility requirements;

- For the more complex shape of perfume bottles and other glass containers, UV laser marking machine is usually used to achieve a more exquisite ablation, the formation of a uniform fine white burr effect, and the formation of a uniform and delicate For more complex shapes of glass containers such as perfume bottles, UV laser marking machines are usually used to achieve a more exquisite ablation, resulting in a uniform and fine white burr effect, and according to the actual shape of the choice of conventional, dynamic rotating, 3D galvanometer or dynamic rotating and 3D galvanometer configuration;

- For medical and pharmaceutical containers that need to be scaled, UV laser marking machines are usually used with a 3D galvanometer to mark the scales, and to achieve a higher contrast permanent scales with the process of black coating of wax after the burr effect is produced.

Glass Gift & Trophy

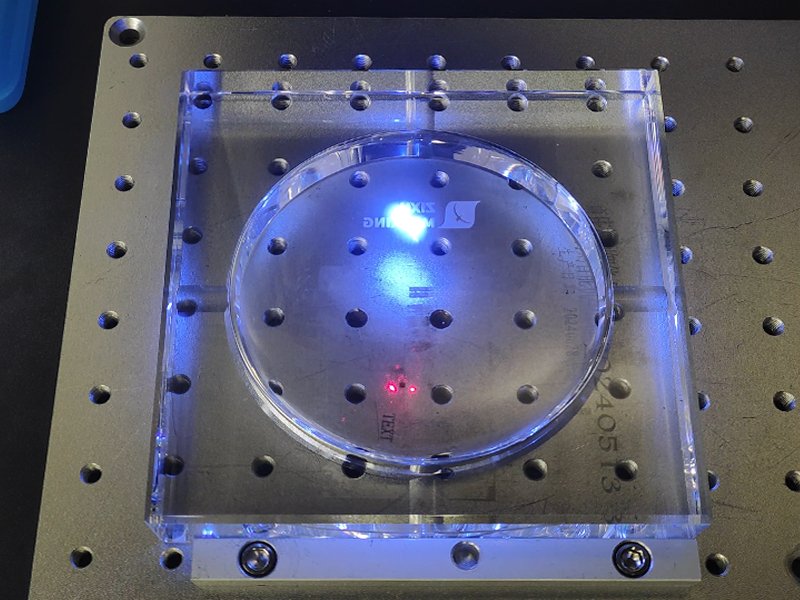

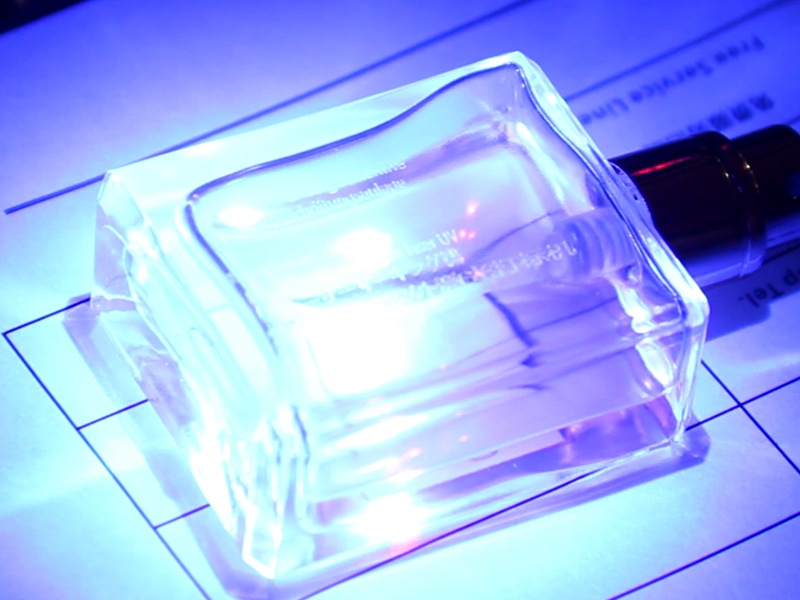

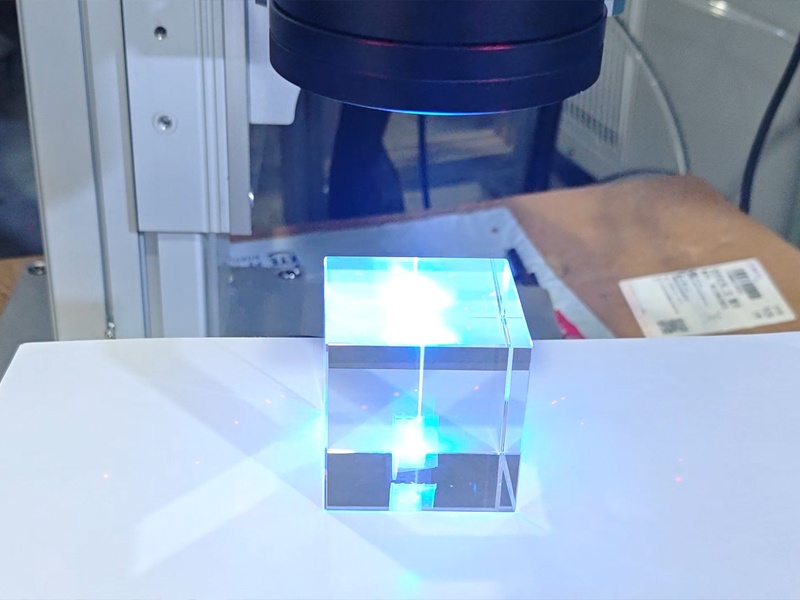

Glasses are widely used as gifts and prizes for commemorative moments, e.g. glass plates, cubes and balls printed with 2D or 3D graphics. Different laser ablation methods and machines are often used to achieve these effects.

For example, for medals made of glass, wood or other materials, the bottom of the medal is usually ablated from the surface with a UV laser marker, which can be combined with a wax filling process to form a permanent logo in different colors, which is then fixed to the other materials with glue or shaped inlays.

For the head, bust or other 3D graphics engraved in the glass cube or ball inside the way, is usually achieved using specially optimized UV or green laser subsurface engraving machine, in which the UV laser formed by the smaller size of the vacuole, can form a more detailed and more three-dimensional graphics, but the efficiency is lower and more likely to be due to the uneven composition of the glass and other factors lead to defects; high transient energy of the green light to form a larger bubble, and its wavelength is slightly longer than the UV laser, the laser beam more than the UV laser, and the laser beam is more efficient, making it easier for the laser beam to pass through the glass and providing more consistent productivity and quality.

3.4. Glass mirrors, windows, doors and walls

Laser etching is now widely used for cutting and marking glass products. For cutting mirrors, car windows, and other shapes of glass, a nanosecond or picosecond infrared MOPA fiber laser is usually used for precise cutting. This type of laser cutting machine can better control thermal effects and stress, improving the yield rate and ensuring processing efficiency. Nanosecond MOPA fiber lasers are usually used for efficient and stable gross or mirror layer stripping for decorative full-length mirrors, large-size smart mirrors, and art glass walls. More cost-effective UV laser marking machines can be used for smaller cosmetic mirrors.

Do You Need Some Advice from Expert?

Due to the wide range of applications of glass, there is a great variety of compositions and uses. Typically, we ask for samples of the glass to be processed, either with our existing lasers or through our strong partner network of laser manufacturers, to ensure that the results and quality of the laser etching will be as good as you need it to be. In addition, we have extensive experience in laser etching of glass products in various industries. If you have a need for convenient marking, cutting, punching, etc. of glass, please contact us for consultation for the best solution.

Recommended Products