Micron-Level Sapphire Laser Cutting: From Sample Testing to Client Satisfaction

Manufactured and natural sapphire are widely used in both the precision electronics manufacturing and jewelry industries. Thanks to its exceptional hardness and optical properties, sapphire has become an irreplaceable material in many cutting-edge applications. One of our U.S.-based clients recently approached us with a request for a complete laser cutting solution for processing hundreds of sapphire components. Their high-purity synthetic sapphire is utilized by several industry giants, including NVIDIA, and must meet extremely stringent optical and mechanical standards. These sapphire materials undergo advanced surface treatment and are then cut into custom fixtures tailored for specific applications.

Due to confidentiality agreements, the client was unable to share detailed application information or provide actual processing samples. However, after thorough technical discussions, we independently used several hundred dollars’ worth of natural sapphire to prepare test samples, demonstrating the efficiency and quality of our precision laser cutting capabilities. These tests served to prove our processing strength and commitment to delivering accurate, repeatable results, even without direct customer samples.

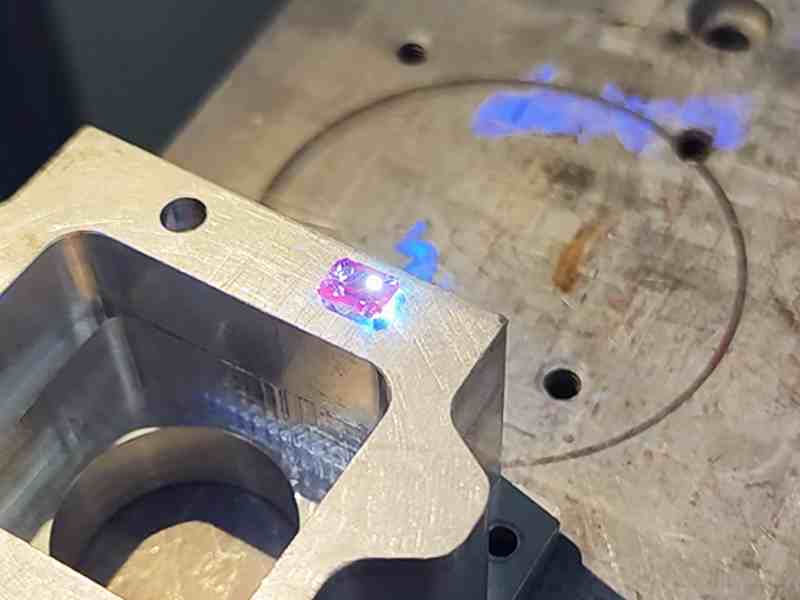

Given the high cost of high-power ultraviolet (UV) lasers, especially picosecond models, we typically do not keep them in stock. Moreover, the customer had a limited budget and preferred not to use expensive picosecond UV lasers. To accommodate their requirements while ensuring high quality, we collaborated with top laser brands including Huaray, JPT, and INNO to source a 30W UV laser for prototyping. This testing process featured GZTech’s 30W UV laser integrated with Sino-Galvo’s 3D galvanometer scanner and a 50×50mm field lens. The cutting performance exceeded expectations—the customer was highly satisfied with both the speed and precision of the cutting results.

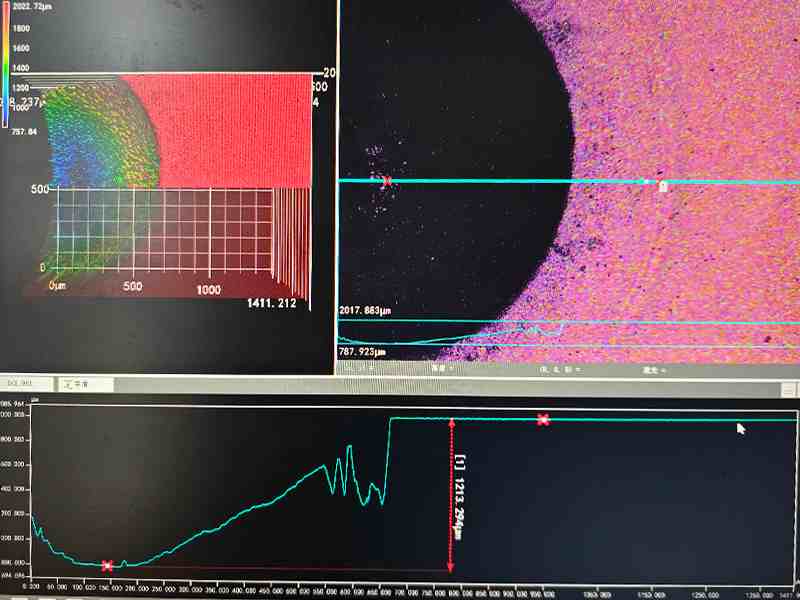

To further validate quality, we conducted a microscopic edge inspection using a CCD electron microscope, as requested. Although some surface contamination was visible in the video and images—mostly caused by ambient dust—the customer confirmed that it was not an issue, since a final polishing step would be applied post-processing.

From a technical perspective, we recommend using ultra-fast picosecond UV lasers for similar precision applications. These lasers offer lower thermal impact, ultra-smooth cutting edges, and eliminate the need for secondary grinding or polishing, resulting in superior dimensional accuracy and tolerance. However, in this particular case, the conventional UV laser still achieved an impressive ±0.001mm cutting tolerance, which fully met the customer’s immediate production needs. The client expressed interest in working with us again if higher precision equipment is required in the future.

Notably, this customer had consulted with over 30 laser marking and cutting machine manufacturers globally. Most of them only proposed fiber, QCW, or MOPA fiber laser systems—solutions that are not ideal for cutting sapphire due to its low absorption at longer wavelengths. We stood out as the first supplier to recommend UV laser systems from the outset. Our technical team explained the unique absorption characteristics of sapphire with respect to various laser wavelengths and clarified why UV and picosecond UV lasers are far superior for cutting brittle, optically clear materials.

The client appreciated our deep technical insight and professional support throughout the process.

If you are in search of a precision laser cutting solution capable of micron-level accuracy—particularly for delicate materials like glass, sapphire, and other brittle substrates prone to chipping or cracking—please don’t hesitate to contact us. We’re ready to provide the optimal cutting solution tailored to your needs.