How to Weld Jewelry – Methods Explained

Jewelry welding is a delicate art that demands experience, skill, and quality tools. Whether it’s a professional jeweler or an enthusiast who wishes to join in, learning to weld jewelry presents new ways of designing, repairing, or customizing jewelry. Here, in this article, we are going to explain how to weld jewelry, especially gold jewelry, and how laser welding became the optimal technique in present-day jewelry-making processes.

Understanding the Basics of Jewelry Welding

What is Jewelry Welding?

In a nutshell, jewelry welding is a method applied to fuse two or more metal components into a lasting union by applying heat, commonly with or without filler material inserted between them. The heat melts the base metals where the two meet to create a solid and continuous bond as the metals set when cooled. Unlike soldering, in which a lower-melting-point alloy (solder) is used to join metals without melting the base metals themselves, welding produces a direct combination by fusion of the materials. This general difference consistently creates a stronger and stiffer joint, especially critical for items subjected to wear and tear.

Metals Suitable for Welding in Jewelry

The success of jewelry welding largely hinges on the compatibility of the metals being joined. Several metals commonly used in jewelry are well-suited for welding, each with unique considerations. Commonly welded metals in jewelry include:

- Gold (yellow, white, rose)·

- Silver

- Platinum

- Palladium

- Stainless steel

Gold, in particular, is highly weldable due to its low melting point and stable chemical properties. However, it still requires precision to avoid discoloration or weakening the structure.

Exploring Common Jewelry Welding Methods

Jewelers employ various welding techniques, each with its own advantages and limitations:

Traditional Soldering

Soldering is the most popular method, where a filler metal (solder) is melted to join two metal pieces together. It is simple and inexpensive, but not as strong or accurate as welding. Suitable for day-to-day repair work and mass production of simple jewelry.

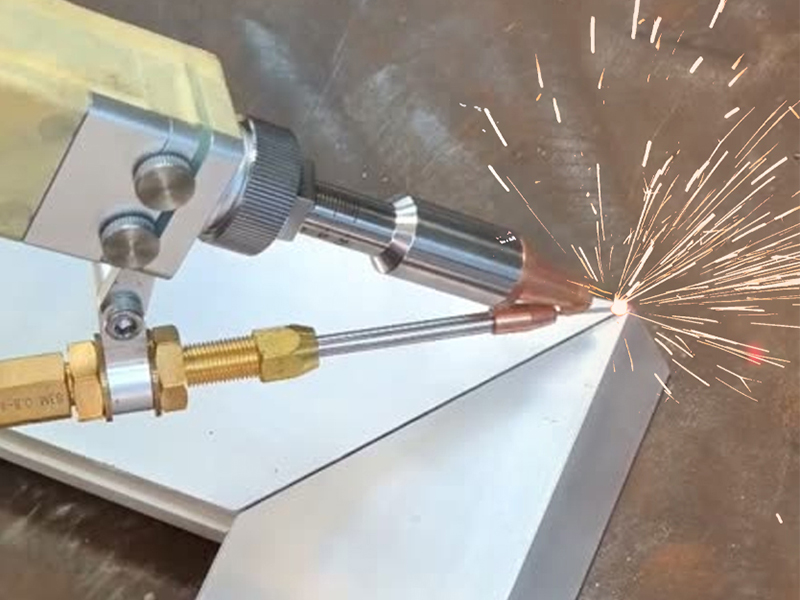

TIG/Micro Welding

Tungsten Inert Gas (TIG) welding or micro welding employs a tungsten electrode to form the weld. It is more precise than soldering and perfect for pieces of small size. It is typically more skilled and slower, though.

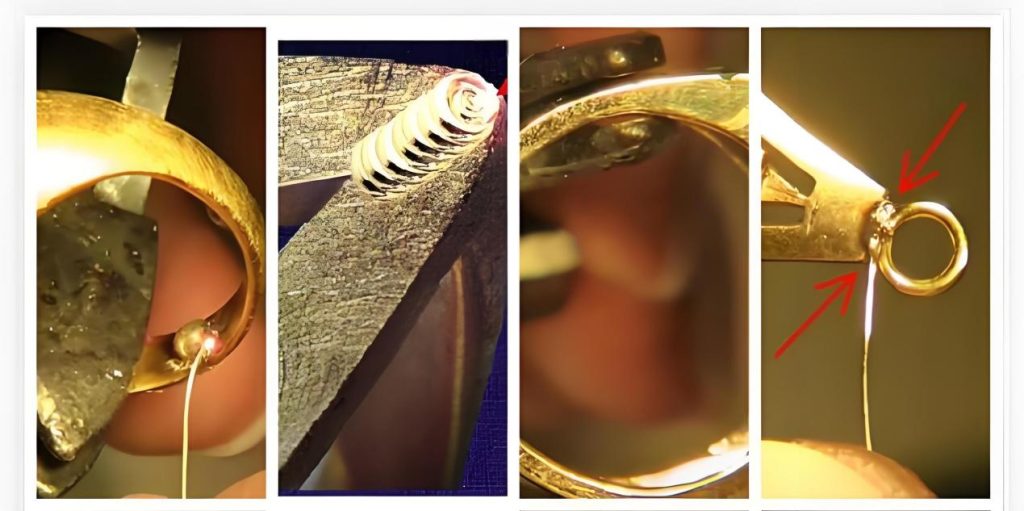

Laser Welding

Laser welding uses a very concentrated beam of light (laser) to fuse metals together. It offers accuracy that is unbeatable with minimal thermal effect, perfect for delicate work on jewelry.

Comparing Laser Welding with Traditional Methods

| Feature | Soldering | TIG/Micro Welding | Laser Welding |

| Precision | Moderate | High | Very High |

| Heat Impact | High | Moderate | Very Low |

| Strength | Moderate | High | Very High |

| Skill Required | Low | High | Moderate |

| Speed | Fast | Slow | Fast |

Why Laser Welding Is the Superior Method for Jewelry Making

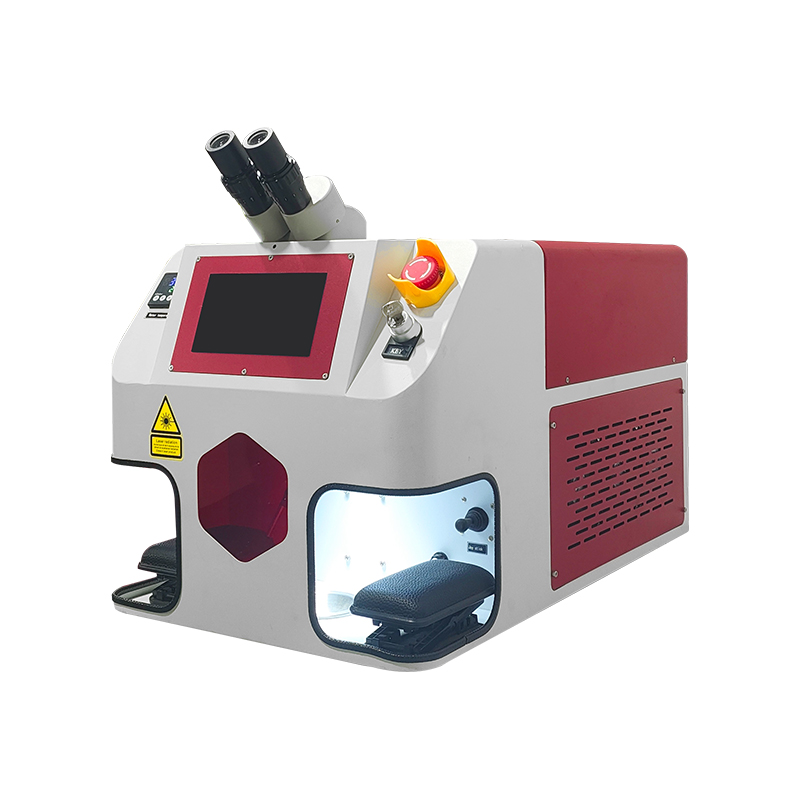

What is a Jewelry Laser Welder?

A jewelry laser welder is a device used specifically to emit a focused laser beam to weld metals accurately. It might have a microscope or monitor, adjustable controls, and foot switches for hands-free operation. They are designed specifically to carry out subtle tasks without damaging surrounding areas.

Advantages of Using a Laser Welder for Jewelry

The adoption of laser welding in the jewelry industry has grown significantly due to its numerous benefits:

- Precision: Excellent for machining intricate items such as prongs, clasps, or links.

- Low Heat Zone: Reduces the threat of heat-caused damage to stones or other components.

- Minimum Discoloration: Avoids oxidation or coloration of metals.

- Efficiency and Speed: Quick operation makes it perfect for mass personalization or immediate repairs.

- Versatility: Perfect for the versatility of metals and applications.

- Non-contact Process: Allows cleaner and more hygienic fixings, especially useful for luxury or antique items.

Types of Jewelry Laser Welders

When selecting a jewelry laser welder, an understanding of the types available in the market is essential. Each type is meant for specific uses, from small artisanal workshops to production-level manufacturing. Below is an extended description of the three primary types:

- Benchtop Laser Welders

Workbench laser welders are compact, self-contained machines that can simply be placed on a workbench. They are ideal for home workshops, single jewelers, or retail stores that require a robust but space-efficient machine. Such units typically feature:

- Integrated microscope or LCD screen to see precisely

- Foot pedal or joystick operation to allow hands-free operation

- Power level control to accommodate different metal types and thicknesses

Benchtop welders are well suited for precision detail work, such as ring sizing, prong re-tipping, repairing chain, or micro-welding tiny pieces. Although compact in size, they deliver high accuracy, stability, and repeatability and therefore are the first preference of jewelers who desire quality and reliability in a compact package.

2. Portable Laser Welders

Portable welders are lightweight and portable, therefore suitable for on-location repair services, trade shows, or jewelers who travel extensively. The machines are portative in design and usually feature:

- Lightweight metal with handles or wheels to facilitate transport

- Air-cooled systems that eliminate complex external cooling

- Brief warm-up time and minimal setup time

Although they are typically weaker than benchtop or commercial units, portable laser welders are more than adequate for typical repair functions like chain repairing, joining repairs, or spot welding on small scales. Their plug-and-play capability and versatility make them especially valuable for mobile businesses or jewelers working from numerous different sites.

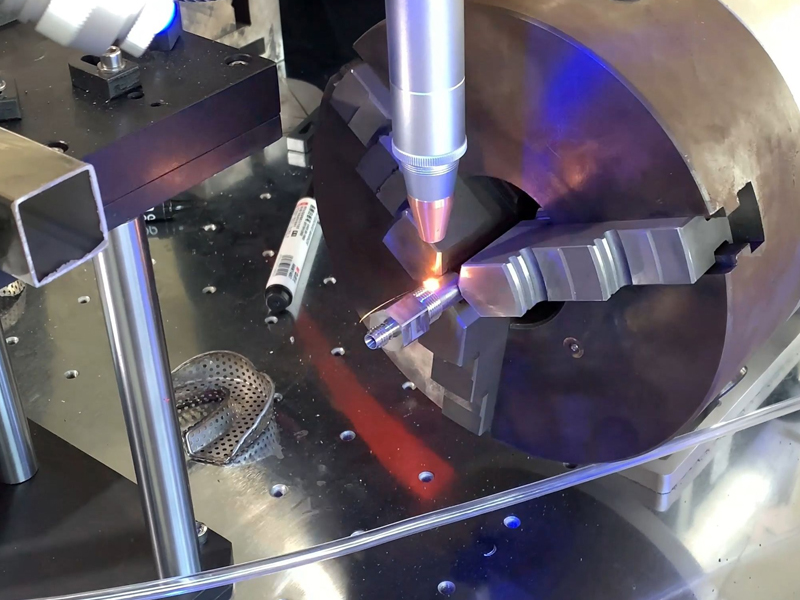

3. Industrial Laser Welders

Industrial laser welders are heavy-duty, big-format machines suited for bulk production, round-the-clock operation, and high-level automation. Generally located in factories, high-volume jewelry shops, and manufacturing units, these welders enable:

- Continuous duty cycles with heavy repetition rates

- Incorporation with CNC systems or robot arms

- Multi-axis travel and programmable parameters for intricate designs

These machines are best used for batch processing, intricate jewelry fabrication, or heavier metal and part welding. Industrial laser welders offer maximum speed, precision, and production capacity, but they typically require more room, more capital, and experienced operators.

Need a Jewelry Laser Welder?

If you’re looking to invest in a reliable, efficient, and high-precision jewelry laser welder, consider the advanced solutions from Zixu. As a trusted manufacturer in the laser equipment industry, Zixu offers a wide range of laser welders designed specifically for jewelers—from compact benchtop units to powerful industrial models. Their machines are known for their intuitive controls, durable construction, and exceptional support services. Whether you’re a studio artisan or a large-scale manufacturer, Zixu has the right solution to elevate your craftsmanship.

Recommended Products