FIVE Most Commonly Used Laser Marking Principles

If you are considering purchasing a laser marking system, we strongly recommend that you learn about the different types of lasers and laser marking processes for various materials and marking effects. This will help you maximize the value of your investment and avoid wasting money and time on ineffective communication and returns when you are unable to achieve your investment goals.

The following are some common laser marking processes that cover a wide range of metallic and non-metallic materials.

- Ablation laser marking

- Photochemistry Laser Marking

- Annealing laser marking

- Foaming laser marking

- Coloration laser marking

In this post, we will introduce you to the principles of laser marking and its common applications. We recommend that you bookmark this article for future reference. Feel free to contact us directly for a test marking or to ask for a solution.

1. Ablation Laser Marking

Ablative laser marking works by directing concentrated laser energy onto a part’s surface until the top layer vaporizes. Because of that, many engineers simply call it laser etching. In practice, operators favour fiber lasers or MOPA sources while marking steel, iron, or anodized aluminum. When the laser runs at high power and slow speed, the mark sinks deep into the metal. By contrast, high-speed passes under the same power leave a lighter, almost white, surface tone. Builders often stack these settings to achieve a gradient effect that is both shallow and deep.

Newer MOPA, green, or UV lasers etch glass, crystal, sapphire, and ceramics, producing a uniform frost. Some equipment vendors even market this frost as a sandblasting option. When tuned properly, the same setup strips away rust, oil, paint, or adhesive while sparing the base material. Researchers are now packaging that capability as a stand-alone cleaning system. For instance, a CO2 beam clears thick rust and grease yet preserves the metal’s original strength. That same source can also peel non-conductive films from clear plastic parts, leaving translucent push buttons behind.

In recent years, both continuous-wave (CW) and pulsed laser cleaning machines have advanced quickly-yet they still function within the broader framework of laser ablation.

Typical applications:

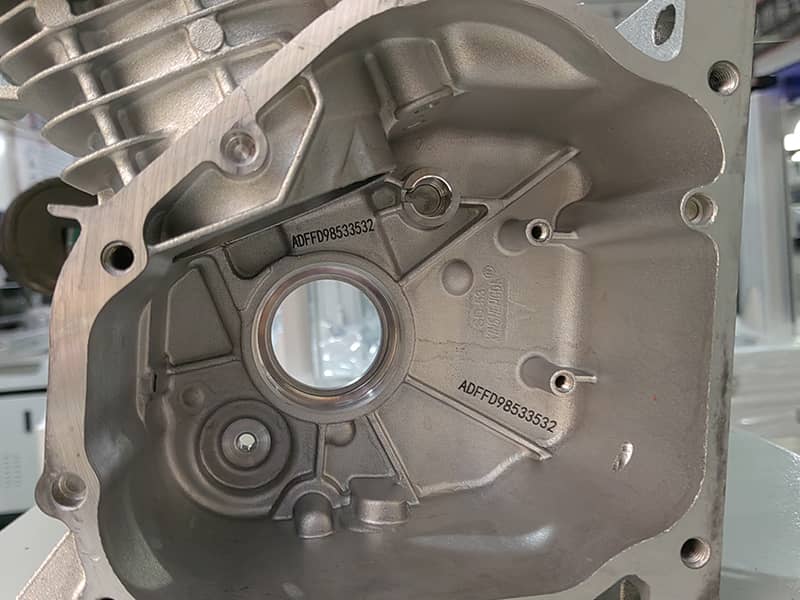

- Fiber and MOPA lasers for direct part marking (DPM) on metal surfaces with slight depth, including serial numbers, QR codes, Data Matrix codes, manufacturer logos, and other information;

- Fiber and MOPA lasers combine low- and high-speed scanning, achieving deep engraving with less burn-in, or create high-contrast black-and-white QR or Datamatrix codes;

- Use UV, MOPA, or green lasers to etch white, translucent, or frosted logos or personalized designs onto glass surfaces;

- Use a UV laser to engrave or cut materials like wood and leather without coloring or melting them.

- Use of CO2 laser ablation on non-metallic materials such as PET and other food and drug packaging for production or expiration date coding, processing of translucent plastic panels and buttons, marking, engraving, and cutting of acrylic, wood, and cardboard.

2. Photochemistry Laser Marking

Photochemistry represents yet another popular technique for laser marking. When the laser strikes the workpiece, its energy excites the atoms, breaking or forming molecular bonds and generating small areas that are either carbonized or oxidized. By fine-tuning the pulse width and repetition rate, operators can create distinct surface microstructures within those layers, yielding permanent colored patterns. Moreover, newly engineered high-power fiber lasers drive carbon closer to the surface through a blend of photochemical and thermal effects, enhancing hardness. This combined approach has come to be known as laser heat treatment.

Typical applications:

- MOPA lasers combine localized carbonization and laser ablation processes to achieve dark gray engraving effects on steel and other metals. They can also produce high-contrast, easy-to-scan black-and-white QR codes with white laser ablation;

- The use of a quasi-picosecond or picosecond infrared laser produces carbonized and oxidized microstructures on the surface of stainless steel or titanium, resulting in a permanently wear-resistant, corrosion-resistant, solid black marking that is commonly used for UDI marking of surgical tools.

- UV and green lasers are commonly used to create permanent black or dark gray markings on plastic surfaces, such as printing production and expiration dates on pharmaceutical and food packaging, and are partly used to print logos, barcodes, and manufacturer information or personalized information, replacing traditional inkjet printing.

- Using a high-power UV laser to stimulate photochemical effects on ceramics results in a black marking or etching effect.

- Use a UV laser to disrupt and reorganize the molecular bonds of silicon on microelectronic circuit boards to create a gold-colored marking effect.

3. Annealing Laser Marking

Laser annealing merges a photochemical reaction with local heat treatment. When a workpiece is flashed with laser light, the metal layer closest to the beam absorbs energy and passes it inward. Some carbon atoms cling to this hot, newly structured surface at the same time. Elevated temperature and the shock front from intense illumination trigger a secondary phase change, causing the surface lattice to recrystallize.

Though intended for marking, this dual action can strengthen the metal and close pre-existing defects. Presently, the technique shines brightest in silicon and carbon chip fabrication, yet in the marking arena it favours bold, lasting black patterns on steel. A 1064 nm fiber or MOPA source is common because that wavelength is nearly transparent to most metals. Such lasers reliably imprint stainless steel, iron, anodized aluminium, titanium, and similar alloys with a dense, uniform black finish. Because the beam is normally out of focus, the effect cannot be mistaken for shallow carbonization, yet the marks resist wear and corrosion far better overall.

Typical applications:

- Annealing and marking of Unique Device Identifiers (UDIs) for medical devices, such as surgical instruments, catheters, and stents, is performed.

- Laser annealing marking is commonly used in the automotive industry to mark metal surfaces, such as aluminum engine parts, exhaust systems, and instrument panels, in black while maintaining the surface finish and avoiding the blurring of markings due to corrosion or oxidation.

- Laser annealing marking is used in the aerospace industry to mark aircraft and spacecraft parts, engine casings, and other metal components. The pure color and resistance to corrosion and abrasion make it easier to perform quality control and trace accidents.

- Laser annealing marking can be used for the advanced packaging of semiconductor wafers. For example, silicon carbide (SiC) wafers are often annealed to ensure the uniformity and stability of their surfaces, and they are marked with identification numbers.

4. Foaming Laser Marking

Foam laser marking is a marking method for plastic materials only that combines the properties of both ablative and photochemical processes. Using fiber or CO2 lasers, this method gently and precisely burns and melts colored plastic surfaces. This creates physical vacuolar structures that alter the material’s light refraction properties, producing different colored markings.

Typical applications:

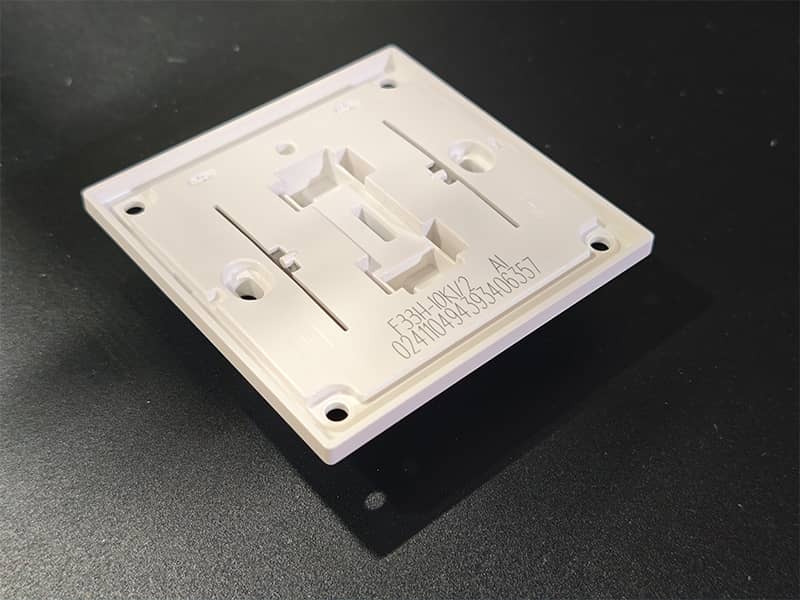

- Use a 1064-nm fiber or end-pumped laser to permanently mark white characters on plastic surfaces, such as on black keyboards and mice;

- Using a 1064nm fiber laser to mark injection molded parts with identification and traceability part numbers or QR codes;

- Use a fiber laser to scan the plastic card with the metal covering to melt and foam the plastic, creating a 3D relief effect;

- Use a CO2 laser to scan transparent PET and other beverage bottles. This process can achieve a certain degree of ablation and melting, forming a visible logo. This method is commonly used for date marking in mineral water production.

5. Coloration Laser Marking

Coloration laser marking relies on localized carbonization and photochemical effects to form microstructures with different optical reflective properties to exhibit different colors on metals, and on foamed laser marking to form microstructures on plastics.

Typical applications:

- Use the MOPA fiber laser to mark colorful, permanent logos or personalize stainless steel or titanium surfaces, such as jewelry.

- Use a UV laser to mark serial numbers on plastic tags such as animal ear tags.

- Use a UV laser to mark a gold QR code inside the cap of a colored beverage bottle.

- Use a picosecond infrared laser to create dazzling, reflective grating microstructures on mirror-smooth steel surfaces. These microstructures can be used for laser anti-counterfeiting or to improve the smoothness of mold runners.

Which Laser Marking Machine Is Right for You?

By this point, you likely grasp the core ideas and techniques behind how lasers interact with materials, and you may have already spotted a specific application that aligns with your requirements. With that background, you should now feel confident enough to discuss your marking objectives and results-and choose the right machine with any manufacturer that specializes in laser marking.

Nevertheless, as you will learn in the Foam or Coloration Laser Marking part of this guide, the same beam can produce quite different effects when the settings are adjusted. Because of this variability, predicting the outcome of a given marking task still hinges on solid know-how and hands-on experience. If you have clear quality targets yet doubt which model or power level to pick, please reach out to us so we can work through the details together.

Recommended Products