A satisfied customer placed a reorder for the customized, automated, in-line laser marking machine

We previously delivered a fully customized laser marking machine for use in a customer’s existing automated production line. After using it for more than a month, the customer was very satisfied with its efficiency. They not only signed a strategic cooperation agreement with us but also placed an order for three sets this month and four sets next month—a total of twenty sets within the year.

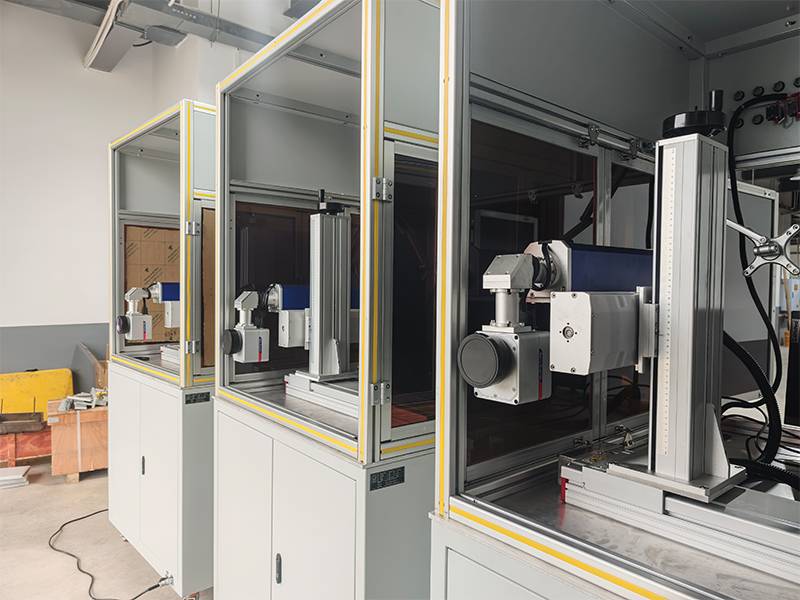

The delivered equipment was identical to the previous configuration and utilized a 100W MOPA laser, an X-axis moving module, a 90-degree steering mirror, and a semi-enclosed cabinet. The software is more complex and uses our Thorx-7 system. If you have experience with Chinese dot peen marking machines, you may be familiar with this software. Since this customer has also deployed our pneumatic dot peen markers based on this system, using the same control system minimizes staff training and increases maintenance efficiency.

The software for the automatic marking machine will connect to the customer’s existing PLC and cooperate with the robot and pneumatic fixture. After the fixture release of the workpiece, it will be moved by the module to the front of the marking machine. Then, the scanning galvo will be moved to the corresponding workpiece marking position on the X-axis. Using the data provided by the PLC for the two-dimensional code, the marking machine will engrave the code on the workpiece with cross-fill black engraving and fast white scanning.

Afterwards, the marking machine will reset to standby, and the moving module will push the workpiece to the next process, which includes scanning the QR code, grading the QR code, and entering the data into the customer’s MES system. The first sample machine marked several hundred QR codes, all of which received an A grade.

Because the machine and production line are highly automated, only technical engineers regularly patrol the line to check the condition of the equipment. We installed laser-proof acrylic panels on all three of the machine’s windows so technicians can quickly check the nodes without wearing protective glasses.