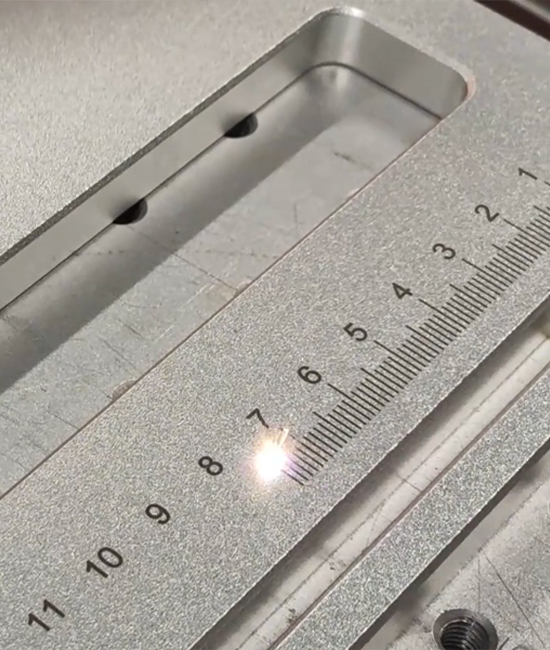

Fiber laser source used by fiber laser marking machine are high power efficiency, the common laser source we used can reach 38% or higher photovoltaic conversion rate, and can mark metals and some plastic materials in an affordable cost. We now have a full range of fiber laser markers from small size handheld use portable model to fully automatic 3D flying cabinet model with CCD camera and dynamic focus and, fully customized machine to meet customers’ exact requirements for best performance.

Key Specification

| Wavelength | 1064nm |

| Marking Speed | Up to 14000mm/s |

| Positioning Speed | Up to 23000mm/s |

| Writing Speed | Up to 600cps |

| Working Temperature | 0~45℃ or 32~104℉ |

Maximize your laser marking productivity.

Over the years, we have worked with a wide range of customers in a variety of industries, from automotive to small batch production of small artifacts, for whom we have designed and manufactured thousands of products with varying degrees of customization, maximizing the efficiency of your marking productivity with our extensive experience.

Focus on laser marking system availability, not price.

Over the years, we have developed strong relationships with many of the industry’s leading laser manufacturers such as IPG, JPT, MAX and Raycus, and have become strategic partners with JPT and Raycus. We typically select the brand of laser source, galvanometer and field lens for our customers with local service to provide the highest level of availability.

Value, eco-friendly and sustainable marking methods

Compared to inkjet or mechanical engraving, laser marking causes no mechanical wear on the part, consumes no consumables, and leaves a clear, permanent mark on the surface without generating pollutants, reducing total life cycle costs and the likelihood of injury, contributing to your sustainable development.

CO2 laser marking machine has great potential because of its ability to mark non-metallic materials, especially leather, clothing and plastics. Nowadays, big companies tried to use CO2 laser marker to provide customized products such as jeans, leather bags, and also, food and beverage companies had been widely used for coding, which is fully automatic mark the production date, expiration date, batch number and more in seconds.

Key Specification

| Wavelength | 1064nm |

| Marking Speed | Up to 14000mm/s |

| Positioning Speed | Up to 23000mm/s |

| Writing Speed | Up to 600cps |

| Working Temperature | 0~45℃ or 32~104℉ |

Maximize your laser marking productivity.

Over the years, we have worked with a wide range of customers in a variety of industries, from automotive to small batch production of small artifacts, for whom we have designed and manufactured thousands of products with varying degrees of customization, maximizing the efficiency of your marking productivity with our extensive experience.

Focus on laser marking system availability, not price.

Over the years, we have developed strong relationships with many of the industry’s leading laser manufacturers such as IPG, JPT, MAX and Raycus, and have become strategic partners with JPT and Raycus. We typically select the brand of laser source, galvanometer and field lens for our customers with local service to provide the highest level of availability.

Value, eco-friendly and sustainable marking methods

Compared to inkjet or mechanical engraving, laser marking causes no mechanical wear on the part, consumes no consumables, and leaves a clear, permanent mark on the surface without generating pollutants, reducing total life cycle costs and the likelihood of injury, contributing to your sustainable development.

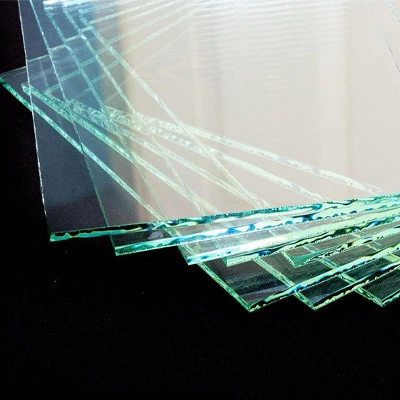

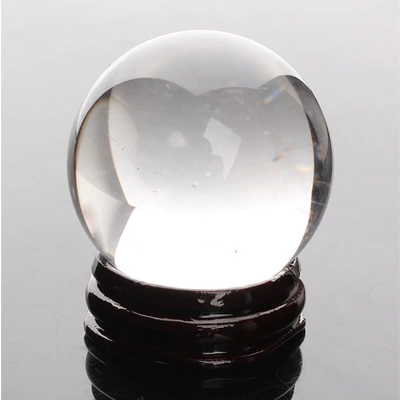

Benefit by the short wavelength of UV laser source, UV laser marking machine provides extremely high precision marking effects, therefore, it is the reasonable choice for marking on small size surfaces such as marking PCB or inside quality trace code inside electronic, and also it is able to mark on glass, crystal and ceramic. Besides, UV laser generates less heat than CO2 or fiber laser on substrate with less damage or loss of substrate, including burning or distortion.

Key Specification

| Wavelength | 1064nm |

| Marking Speed | Up to 14000mm/s |

| Positioning Speed | Up to 23000mm/s |

| Writing Speed | Up to 600cps |

| Working Temperature | 0~45℃ or 32~104℉ |

Maximize your laser marking productivity.

Over the years, we have worked with a wide range of customers in a variety of industries, from automotive to small batch production of small artifacts, for whom we have designed and manufactured thousands of products with varying degrees of customization, maximizing the efficiency of your marking productivity with our extensive experience.

Focus on laser marking system availability, not price.

Over the years, we have developed strong relationships with many of the industry’s leading laser manufacturers such as IPG, JPT, MAX and Raycus, and have become strategic partners with JPT and Raycus. We typically select the brand of laser source, galvanometer and field lens for our customers with local service to provide the highest level of availability.

Value, eco-friendly and sustainable marking methods

Compared to inkjet or mechanical engraving, laser marking causes no mechanical wear on the part, consumes no consumables, and leaves a clear, permanent mark on the surface without generating pollutants, reducing total life cycle costs and the likelihood of injury, contributing to your sustainable development.

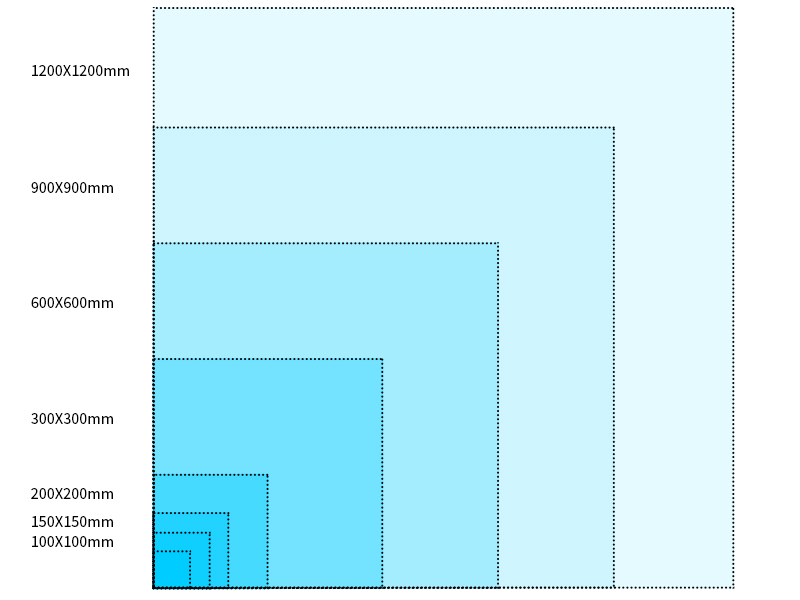

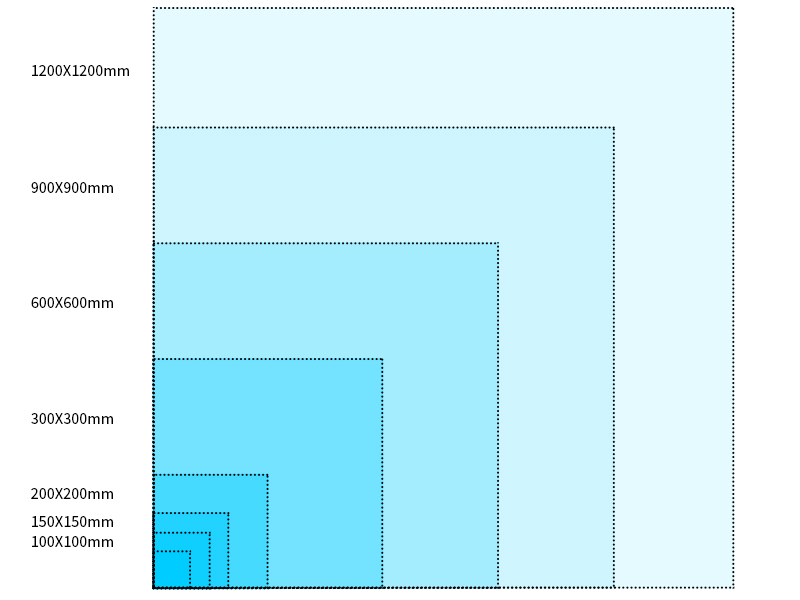

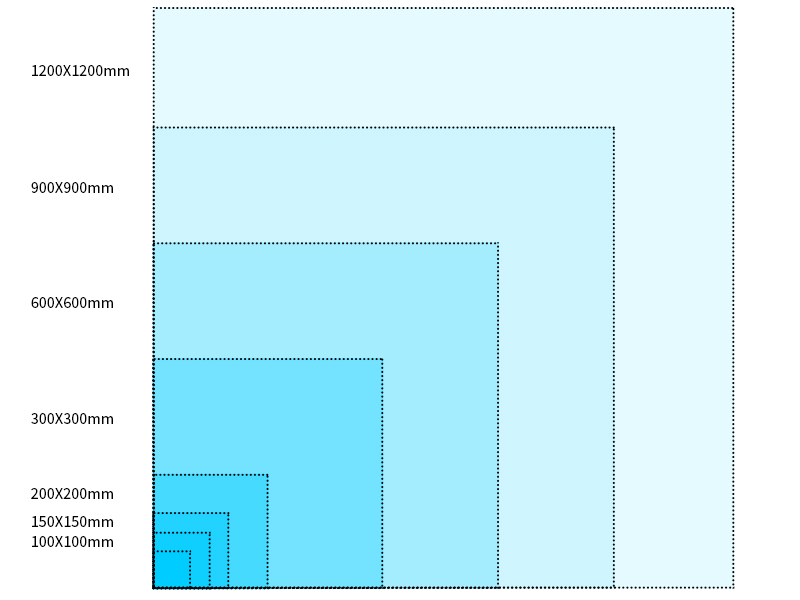

Material compatibility of our laser type

Review the material you want to mark or engrave. Check out our material application pages for real-world cases.

| Material to mark or engrave | Fiber | MOPA | UV | CO2 |

| Metals | √ | √ | ○ | – |

| Precious Metals | ○ | √ | ○ | – |

| Plastic | ○ | √ | √ | √ |

| Glass | – | ○ | √ | ○ |

| Ceramics | – | – | √ | √ |

| Acrylics | – | ○ | √ | √ |

| Leather | – | – | √ | √ |

| Wood | – | – | √ | √ |

| Stone | – | – | ○ | √ |

| Textile | – | – | √ | √ |

| Paper | – | – | √ | √ |

| Carbon Fiber | – | – | √ | – |

Tips:

√ means the laser type is ideal for marking or engraving these materials;

○ means the laser type will work to mark or engrave these materials, but the requirements are more demanding;

– means the laser type is not recommended for the job.

Marking Samples

Why Choose Zixu Laser Marking Machine?

Our fast and accurate marking solution works on a wide range of materials including metal, plastic, wood, leather, glass and more. It is capable of marking highly visible, high-resolution images or text in any environment.

Precision and legible

laser marking offers a higher resolution than mechanical marking systems, with smoother edges than mechanical marking and no burr;

Permanent marks for traceability

laser marking provide superior resistance to abrasion and corrosion, and QR or barcode markings inside for quality tracking;

Environment friendly

laser marking produces far less substrate loss, noise, airborne particles and pollution than mechanical marking or inkjet printing;

Nimble deployment

our laser marking machines can be used in a basic tabletop version or optionally with modules or a robot for heavy-duty applications.

Clients who chose our laser marking and engraving machines.

Want an un art handing video demonstration on specialized material? Looking for a solution to your specialized environment or automatic process demand?