Dot Peen Marking Machine VS. Stamping Machine: How to Choose?

In permanent part identification in manufacturing, dot peen marking and stamping are two of the most prevalent methods being utilized. Although both are methods that leave permanent marks, they function on essentially different principles, which makes each one ideal for particular applications.

Selecting the proper marking process is based on various factors, such as material type, production volume, mark durability requirements, and desired operational flexibility. In this article, we will present the key differences between dot peen marking machines and typical stamping machines, guiding you to the appropriate decision.

Mechanism of Dot Peen Marking Machine

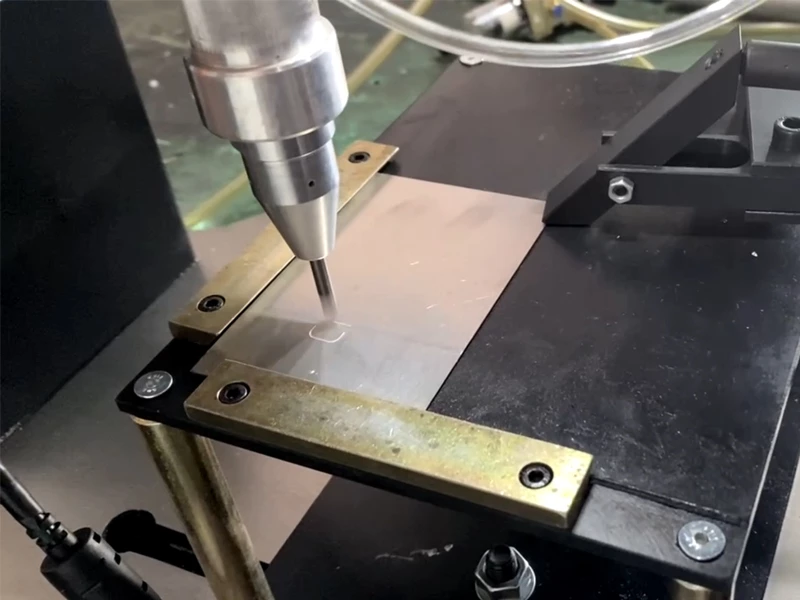

Dot peen marking machines work by employing a precision-controlled stylus that quickly taps materials’ surfaces, leaving permanent indentations behind. Once activated by digital input (most commonly text, numbers, barcodes or logos from software connected to it), its carbide or diamond-tipped stylus travels along X and Y axes and taps the surface in an ordered sequence to produce close spaced dots resulting in crisp marks with high contrast for excellent readability.

Dot peen marking allows for precise control over its marking force depending on the hardness of material, with an optimal depth that does not cause deformation. Dot peen marking exerts minimal downward pressure compared to traditional engraving or stamping methods and is well suited for thin and brittle materials; more modern models even feature servo-driven accuracy to achieve ultra-fine detail development.

Key strengths of this strategy include:

- Non-contact marking minimizes material stress.

- Programmable flexibility (instant design change without physical tooling)

- High repeatability (consistent marks for traceability purposes)

It is widely used across industries that need permanent identification of parts, such as automotive, aerospace, medical devices, and electronics manufacturing. Whether it is serial numbering on engine components or data matrix marking on surgical tools, dot peen machines provide durable, high-resolution output with minimal maintenance.

Working Principle of Stamping Machine

Stamping machines, commonly referred to as metal stamping presses, employ high-pressure forces to stamp permanent markings onto workpieces. A hardened steel die that features text or graphics is applied using mechanical or hydraulic force against its surface with significant force from either mechanical or hydraulic pushers, dislodging metal from its place and creating sharp marks legible even under adverse circumstances.

Stamping machines generally fall into two general categories: manual (hand presses or hammer stamps) and automatic (pneumatic, hydraulic, or servo-electric presses). Manual machines offer cost-efficient options for low production runs, while automatic systems deliver speed and consistency in high production environments.

Key Technical Details

- Die-Based Marking: Each stamp requires a custom-made die, limiting flexibility but ensuring consistency.

- High Force Application: Typically ranges from a few hundred to several thousand pounds of pressure, depending on material hardness.

- Material Deformation: Unlike non-impact methods, stamping physically alters the surface, making it ideal for heavy-duty metals like steel, titanium, and hardened alloys.

Stamping is superior in applications where mark durability is of utmost importance, including automotive forging, military hardware, and industrial tooling. Less versatile than dot peen marking, its permanence and speed render it invaluable for high-rate metal part identification.

Comparison Between Dot Peen Marking and Stamping

Dot peen marking and stamping are both reliable techniques for permanently marking materials, yet these methods vary substantially in their functionality, application, and results.

Dot peen marking is widely recognized for producing permanent marks with pinpoint precision using controlled indentations created with a stylus stylus, making it suitable for marking serial numbers, logos or QR codes on hard surfaces such as steel or aluminum with traceability and legibility being key components in industrial environments where traceability and legibility over time is of critical importance. Dot peen machines can even be programmed for variable data marking applications in production lines and automated production lines.

Stamping, on the other hand, is an extremely high-speed method that employs mechanical force to press a shape or text onto surfaces quickly and efficiently. Stamping makes mass production much more cost-effective as its designs can be repeated across numerous items without changing dies and may not provide as detailed or precise results as dot peen marking. Stamping may therefore be best used with soft materials where speed overrides flexibility or detail requirements.

Here’s a summarized comparison between the two methods:

| Feature | Dot Peen Marking Machine | Stamping Machine |

| Marking Method | Mechanical stylus creates dot patterns | Die and punch imprint the surface |

| Precision | High – suitable for fine details and codes | Moderate – suitable for basic shapes/text |

| Material Compatibility | Hard metals, plastics, coated surfaces | Softer metals, plastics |

| Speed | Moderate | High – ideal for high-volume production |

| Flexibility | Highly flexible – supports variable data | Low – fixed design per die |

| Automation Capability | Easy to integrate with automated systems | Limited automation compatibility |

| Maintenance | Low – fewer wear parts | Moderate to high – dies wear out |

| Cost Efficiency | Cost-effective for medium/low volumes | More cost-effective for large volumes |

By understanding these distinctions, manufacturers can select the right marking technology that aligns with their operational needs and production goals.

Which Type Should You Choose

Choosing between dot peen marking and stamping ultimately depends on your production requirements, material characteristics, and marking specifications. Here’s a detailed breakdown to help guide your decision:

When to Select a Dot Peen Marking System

Dot peen technology excels at applications requiring precision, flexibility, and minimal material impact. This method can prove especially valuable when:

- Need High Definition Marks – Electromechanical styli can produce precise alphanumeric text as small as 0.5mm, machine-readable 2D code, and even complex logos with remarkable legibility.

- Your materials are sensitive to deformation – unlike stamping, dot peen applies minimal force, making it ideal for thin gauge metals, coated surfaces, and fragile materials that could warp under higher pressure such as thin gauge metals and coated surfaces that might warp under more substantial force from stamping presses.

- Your content requires regular modifications – A software-driven operation makes switching part numbers, serial codes, or batch information quickly without physical tooling modifications being necessary.

- Automation integration is of utmost importance – modern dot peen markers easily integrate with robotic arms, CNC machines, and conveyor systems for inline marking applications.

When Traditional Stamping Delivers Better Results

Stamping remains the best option for heavy industrial applications where unparalleled durability and high-speed operation are necessary. Think stamping when:

- Mark permanence is absolute: The deep impression created by stamping withstands abrasion, heat treatment, and harsh environmental conditions better than any other marking method.

- You are dealing with high volumes of similar components: Once the die has been created, stamping provides uniform impressions at rates several times higher than other methods, often doing this in seconds per impression.

- Operating costs must be minimized: With no electricity, consumables, or complex electronics required, stamped marks have the lowest per-unit cost in high-volume production.

- You’re dealing with strong, tough materials: stamping shines best when used on forged steel, cast iron, and similar heavy metal, where other techniques are likely to fail.

For uses that include marking a broad variety of materials or call for both flexibility and sturdiness, some manufacturers choose to use both technologies—utilizing stamping for more rugged components and dot peen for more precise applications. Ultimately, the optimal solution tends to come down to running material tests using your own components to establish mark quality, speed, and durability.

To Sum Up

In conclusion, the selection between a dot peen marking machine and a stamping machine is based on understanding your marking needs, types of material, and production volume. Both machines possess varying strengths in terms of accuracy, speed, and flexibility. By weighing these against your operations, you can make an informed decision that best suits your manufacturing operations. Need any help? You may freely contact our technical team.

Recommended Products