Common Leather Laser Marking Issues You May Face

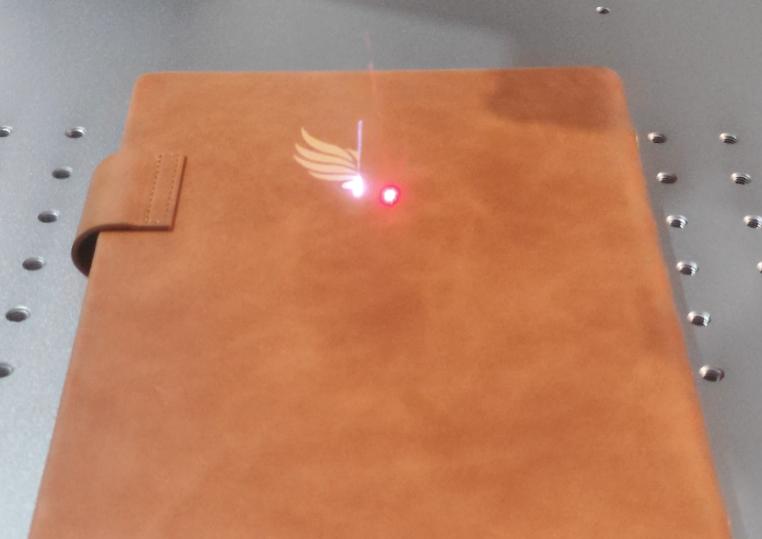

Across industries like fashion, automotive interiors, and luxury goods manufacturing, Leather Laser Marking is an exact and flexible technique employed to make logos, serial numbers, decorative patterns, and custom engravings. It does not physically touch the object and works best on gentle materials. It also applies to leather and delivers high-quality results. Although the right technology is available, we run into problems with the finishing touches. Some common problems we face while laser marking on leather are burn marks, uneven engraving depth, poor contrast, and engraving residue buildup. Let’s take a deep look at it.

Can Laser Marking be used on Leather?

Sure. Laser marking on leather is not only possible but has recently become a go-to for adding intricate details and permanent identification on leather goods. It employs a highly focused beam of laser that works on the surface of the leather and permanently marks scars on it. These marks will not fade, peel, or rub off irrespective of the passage of time. This makes it suitable for everything from branding luxury handbags to adding functional markings on industrial leather components.

Unlike traditional stamping or even printing, laser marking does not need any sort of physical pressure that could affect the item’s shape and texture. With laser technology, it is possible to create intricate patterns, micro-text, and even subtle shading which would be difficult with manual techniques. This technology does not suffer from errors, meaning that every item in a production run is the same as the other.

As with other techniques, laser marking can be tailored to different finishes of leather and remain professional for decorative and functional works. Different applications for decorative and functional purposes can be applied without losing polish.

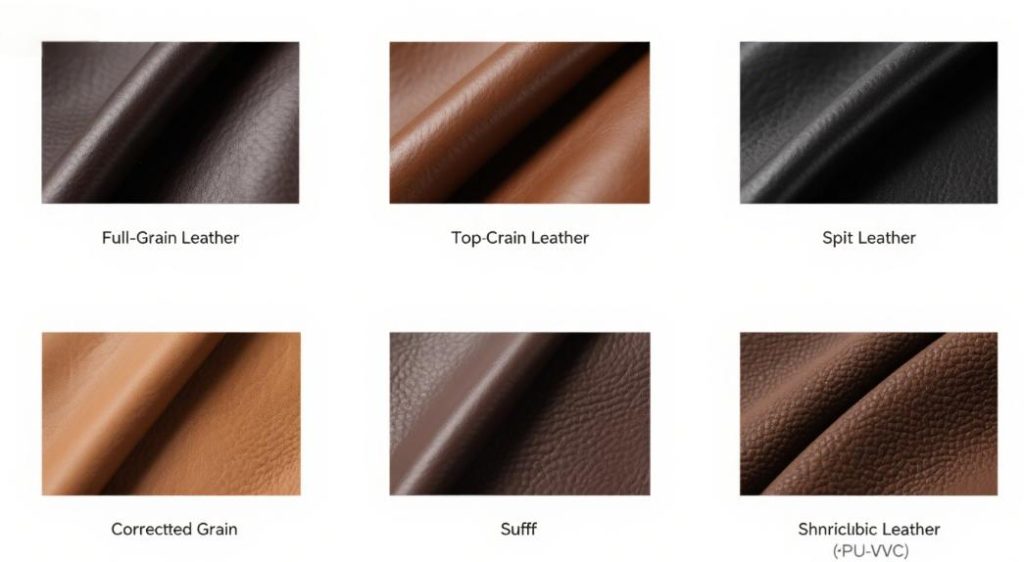

Different Types of Leather for Laser Marking

Not all leather types respond uniformly to laser marking. The engraving’s quality is influenced by marking’s composition, treatments done to the surface, and the material’s thickness. Grasping these variances enables setting selection that prevents expensive trial-and-error.

- Full-Grain Leather

Full-grain is the highest quality natural leather. Like all leathers, full-grain develops a rich patina, sharp, and dark impressions from laser marking. The full-grain leather has minimal surface treatment which helps with overheating, however, the full-grain’s treatment makes excess heat control crucial.

- Top-Grain Leather

Top-grain leather is the more worked version, now with a rough finish it is more approachable than full-grain. Like full-grain, it too has uniform laser marking, however the top layer treatment adds uniformity to the contrast.

- Split Leather and Corrected Grain

The split leather is the lower layer of the hide and often has top coatings to hide blemishes. These coatings react differently with the laser causing erratic or lighter burns, which exposes the layered defects beneath.

- Suede and Nubuck

These leathers have soft, velvety texture from sanding, require lower power and fast engraving to prevent scorching the delicate fibers. Like full-grain and top-grain, they still require layering to retain detailing which helps control to excess power.

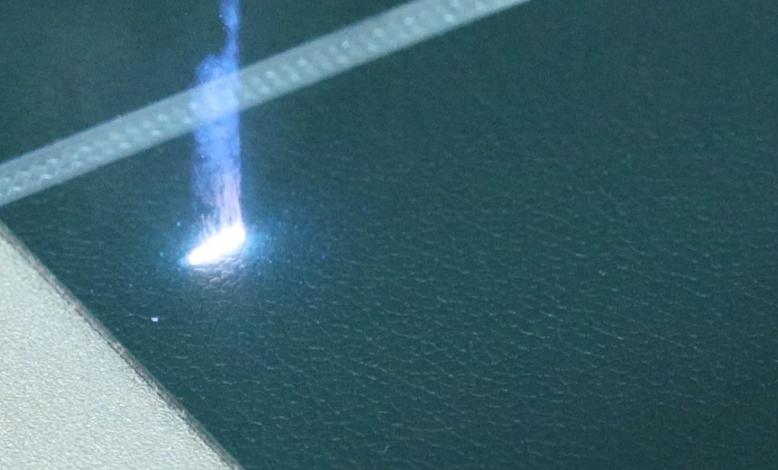

- Synthetic Leather (PU, PVC)

Plastic-based surfaces, which can be PVC or PU, are used to make artificial leathers. When lasers are used on such materials, the surface can either melt or give off noxious gasses. Nonetheless, marks can be created, provided that there is enough airflow and the settings used are precise enough.

For obtaining crisp, uniform, and sharp contrasts as well as high-quality results on leather marking, it is imperative to select the correct leather type and also the settings required. The results are dependent on each of the two steps.

Common Leather Laser Marking Issues

Working with leather still has issues that affect its quality and consistency even when using modern technology tools like laser markers. Knowing the basic troubleshooting techniques for the most common problems allows for a more consistent and polished outcome.

Burn Marks and Scorching

Out of all the problems encountered when laser marking on leather, burn marks seem to be the most common. This is the result of excessive power and slow engraving as mentioned before. Overheating equipment can also cause strong odor and burning of the threads. Decrease in leather quality and endurance is also a result of burning. Uneven leather consistency and a thick leather structure can also worsen burning. Burn marks can be avoided using a reasonable adjustment to 70% laser power at a slower mark speed.

Uneven Engraving Depth

Inconsistent or uneven engraving depth, caused by irregular surfaces of leather, warped materials, or incorrect laser focus, is a common engraving problem. On leather pieces with natural contours, some areas may accept more heat energy than others, resulting in deeper marks, while some areas of the engraving remain faint. Depth inconsistency will engrave logos, patterns, or serial numbers in an unprofessional manner, thus reducing the readability of the marks. This problem can be minimized by ensuring a flat surface, accurate focus calibration, and running tests on samples of the leather.

Poor Contrast or Faded Marks

Poor contrast between the engraving and background is often an issue, which makes text and logos under laser marking look sharp and visually attractive. Covered or finished leather pieces have a pigmented surface which acts as a barrier to energy absorption resulting in faint and dull designs. For intricate logos and text that are crucial to branding and recognition, such exposure is disastrous. Furthermore, to maximize contrast, using leather that is not covered with a surface finish or is covered with light finishing is recommended along with optimizing the rest of the laser settings.

Edge Charring and Cracking

Charring and cracking are two problems that are more common on the edges of delicate and thin pieces of leather. The use of a laser of too high of a power can dry out fibers, which leads to brittle and brittle spliting along the cut or engraved line – thus, damaging the visual aspect and the strength of the piece. Utilizing multiple lower powered lite passes with proper laser alignment and less dwell time improves leather edge burning, while still maintaining a professional look.

Solving these four problems let the operator effectively balance automation with artistic skills, greatly improving the efficiency of waste material, time, and delays.

How to Prevent These Leather Laser Marking Issues

To avoid problems caused by leather marking with lasers, one needs an understanding of both the material and the machine. With a more systematic approach, one is able to achieve high quality leather marking results with minimal waste with little to no production delays.

- Optimize Laser Power and Speed: To avoid burning and scorching, it is critical to start at low power and fast speed and gradually increase to higher settings whilst monitoring the results. Avoiding the use of single deep engravings helps to stave off excess charring and heat buildup.

- Focus and Material Positioning: Uneven engraving depths are caused by either poor material focus and planar surfaces. Securing leather on flat surfaces helps, but make sure to set focus before starting to engrave. Focus settings must undergo trial and error on scrap pieces of leather until the set focus helps achieve uniform engraving to ensure best results on final pieces.

- Leather Selection and Masking Techniques: Poor contrast is improved by untreated leathers and lightly finished ones. Masking techniques involve the application of heat resistant masking tape on coated and synthetic leathers which helps increase the contrast whilst protecting the material from burning and excessive heat.

- Avoid Edge Charring and Make Sure There’s Airflow: When cutting, do not use a single high-powered pass. Using a lower powered cut with multiple passes helps to avoid edge charring and cracking. An air-assist and proper ventilation helps to remove heat and smoke, which helps keeps both the leather and the workspace clean.

- Make Adjustments and Do Regular Monitoring: Before doing full production, always do small-scale tests on a sample piece of leather to avoid wasting materials. Make sure to keep an eye on every engraving while making appropriate changes to the settings so that every piece looks the same. Time can be saved on future production runs when accurate yet effortless settings can be recorded for every leather type.

Proper calibration of the machine, selection of materials, and making sure the environment is within set standards will go a long way in eliminating common issues that arise when laser marking leather and will allow for absolute consistency and mastery every single time.

Where to Find an Efficiency Leather Laser Marking Machine?

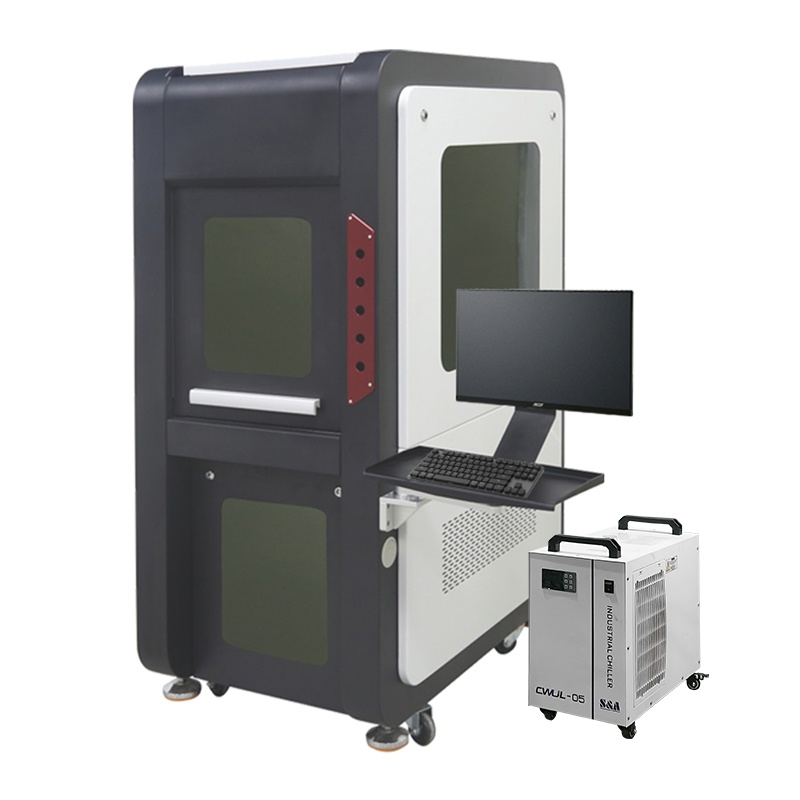

When looking for a high-efficiency leather laser marking machine, Zixu is a trusted manufacturer to check out. Zixu makes laser systems like CO₂, fiber, and UV lasers, which are used on non-metal materials such as leather, wood, and plastics.

Configurability and service are what stand out with Zixu as a manufacturer. For each CO₂ unit for natural leather or UV/fiber units for coated surfaces, we have multiple form factors and power options, including desktop, handheld, flying/inline, and rotary.

We are present as custom manufacturers, which include OEM/ODM capabilities with international sales channels and after-sales support, including warranty and online services. You can order custom bed sizes, custom ventilation packages, or control programs for leather marking for your branded devices.

Before buying, you can ask for: sample tests on your leather, documented settings for the leather type, and details on ventilation/air-assist options. Feel free to contact us!

Recommended Products