Precise Fiber Laser Cutting Machine

Since 2016, we have received requests from some of our long-standing laser marking machine customers for metal cutting solutions. Coinciding with the research and development of high-power fiber and MOPA lasers by brands such as Raycus, Max, and JPT, we have gradually entered the fiber laser cutting machine market.

Currently, using fiber lasers for metal cutting has become a common application and industrial standard. Such equipment has now branched into various different development paths. Compared to the commonly used large-format gantry-type fiber laser cutting machines, we focus more on precision laser processing of high-precision small and medium-sized metal and non-metal materials.

For product pricing, customization, or other inquiries:

Description

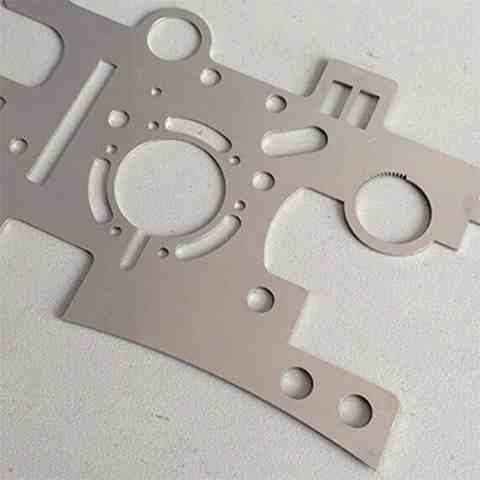

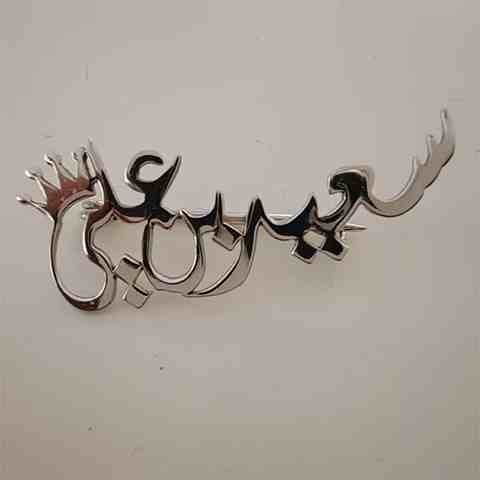

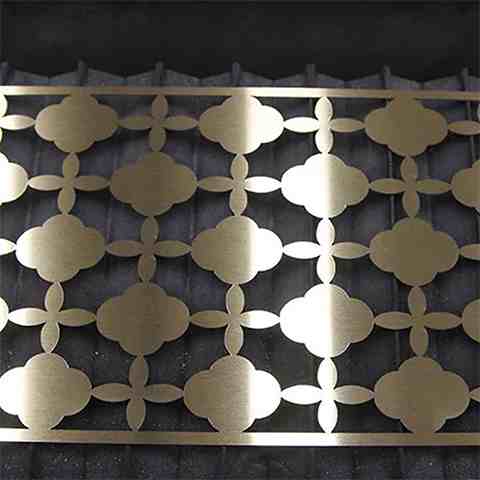

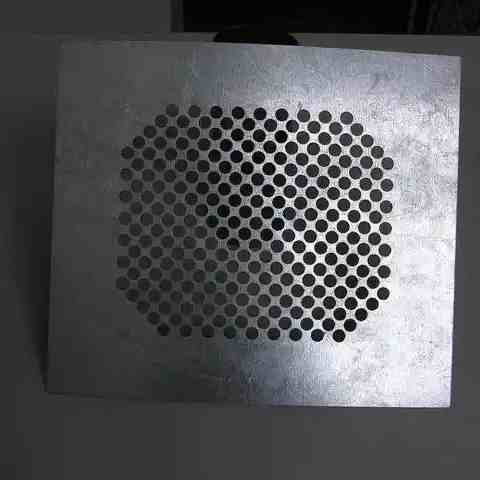

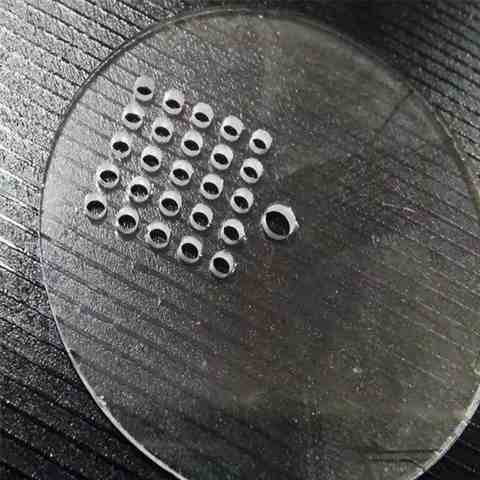

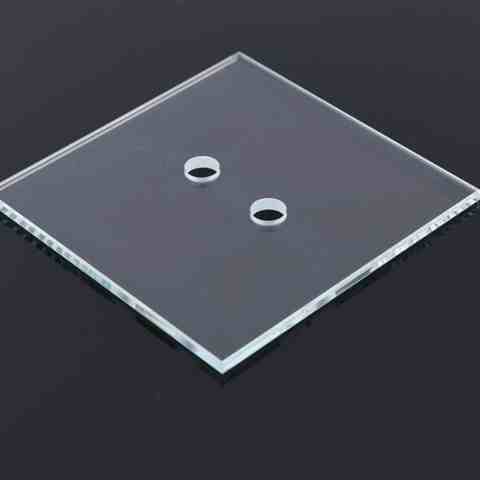

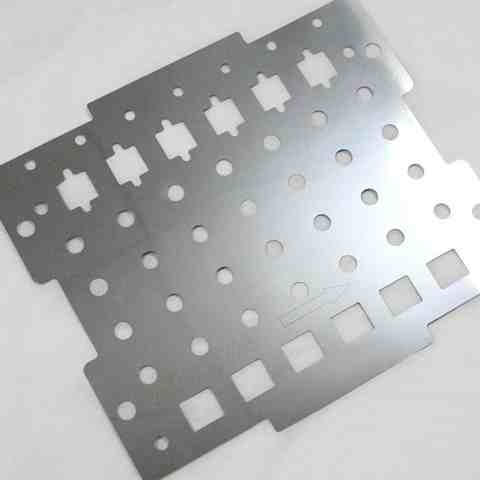

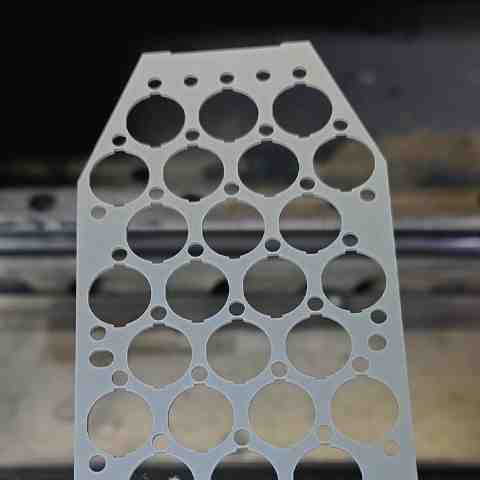

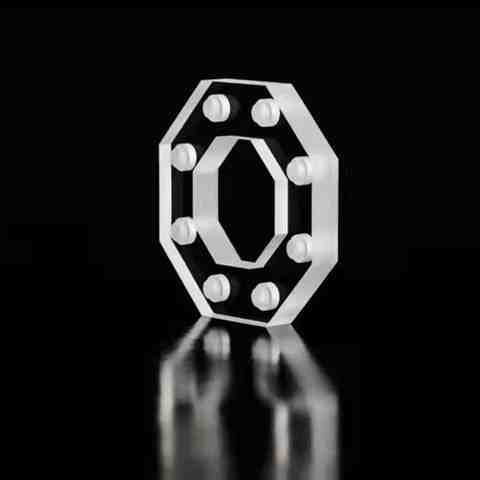

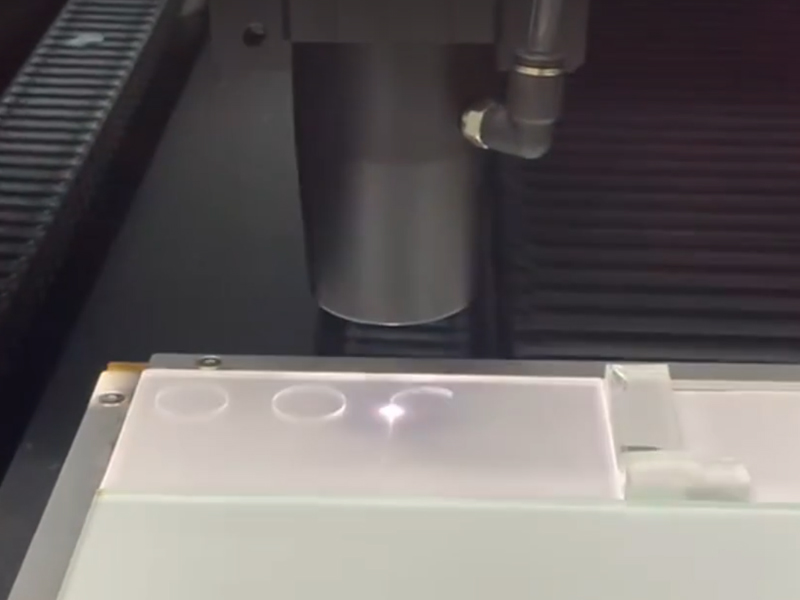

This type of precision fiber laser cutting machine operates on a principle similar to that of the more common large-format gantry fiber laser cutting machine, but typically employs servo motors with higher positioning accuracy and faster acceleration instead of stepper motors. It can be equipped with MOPA fiber lasers with superior beam quality and energy control, combined with components such as enclosed cabinets and exhaust systems, to achieve flexible objects processing including precise cutting, drilling and scribing on metal sheets, metal foils, precious metal jewelry, optical glass, silicon circuit boards, and other workpieces.

description

Compared to conventional gantry-type large-format fiber laser cutting machines, precision fiber laser cutting machines also often use a gantry structure, but they place greater emphasis on lightweight design to minimize dynamic deformation during high-speed cutting. Additionally, conventional gantry-type large-format fiber laser cutting machines typically use gear-rack drives, which are fast but have relatively lower precision, with positioning accuracy typically around ±0.05mm. In contrast, precision fiber laser cutting machines, due to their different application purposes, typically use high-precision servo motors and linear guides to achieve positioning accuracy of 0.01mm or even 0.001mm.

Material cutting compatibility with different laser source.

| Material / Laser Type | Fiber Laser | MOPA Fiber Laser |

| Metal sheets | √ | √ |

| Metal foil | ○ | √ |

| Plastic | ○ | √ |

| Glass | – | √ |

| Ceramic | – | ○ |

| Silicone | – | √ |

| Gemstone | – | ○ |

Tips:

√ means the laser type is ideal for cutting this type of material;

○ means the laser type is able to cut this type of material, but there are some limits;

– means the laser type is not recommended for the job.

Clients who chose our handheld pneumatic dot peen marking machines

Want an un art handing video demonstration on specialized material? Looking for solution of your specialized environment or automatic process demanding?

This type of precision MOPA fiber laser cutting machine is equipped with a high-performance MOPA fiber laser on the basis of a precision fiber laser cutting machine. It provides higher laser beam quality and instantaneous energy, and can also achieve precision processing of more materials by adjusting the pulse width duration and pulse frequency. We typically configure different brands and models of lasers based on the actual materials our customers need to cut and their target quality requirements. These lasers are often specifically designed and optimized for these niche applications, with the JPT M8 series being the most well-known.

description

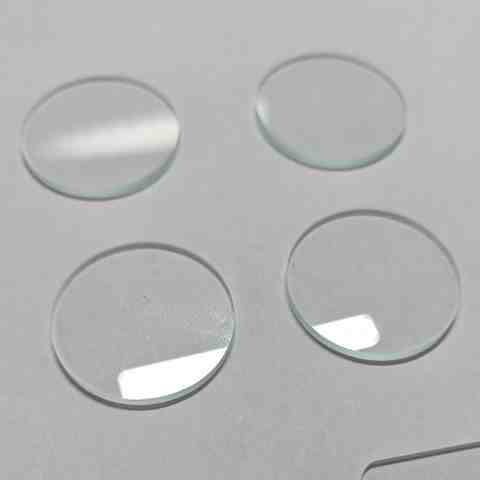

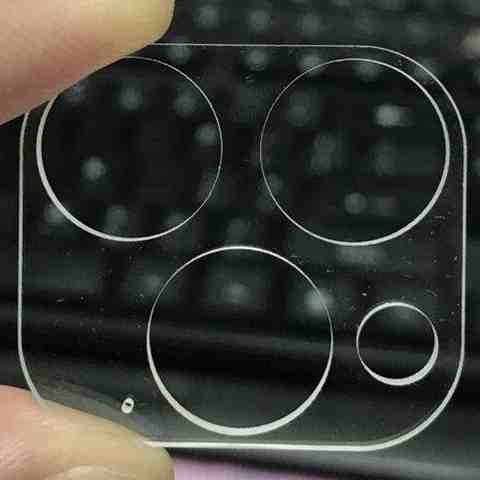

Compared to precision fiber laser cutting machines equipped with conventional high-power fiber lasers, the use of high-performance MOPA fiber lasers enables processing of materials other than metals. For example, glass is a material widely processed using such MOPA lasers. Common applications include smartphone screens and tempered glass films, LCD and LED display glass panels, and photovoltaic glass, all of which are produced using precision MOPA fiber laser cutting machines.

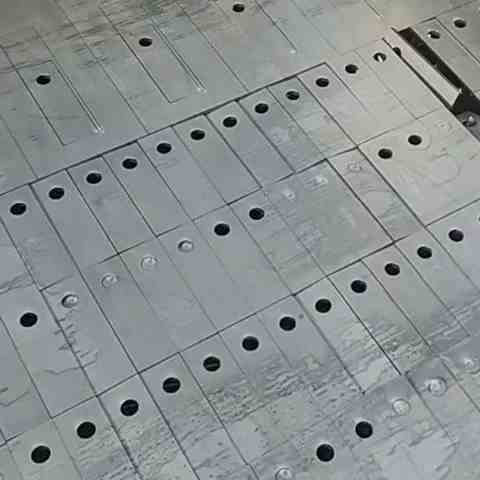

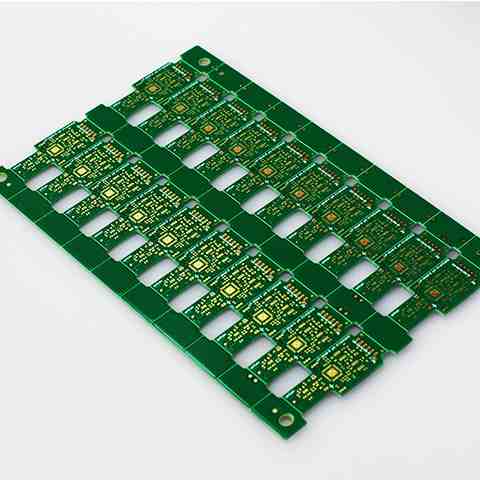

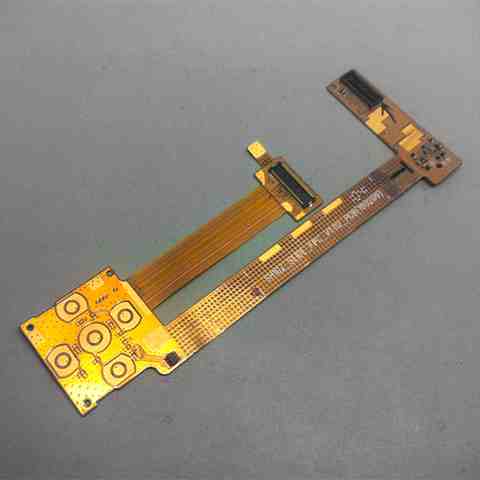

Additionally, during the flexible production of conventional silicon circuit boards, precision MOPA fiber laser cutting machines can be used for drilling holes, milling grooves, and cutting. Such applications are commonly found in the home appliance and consumer electronics industries. These products often employ modular designs, where multiple separate circuit boards carry different functional modules such as power supply modules, I/O panels, and display panels. Using precision MOPA fiber laser cutting machines significantly enhances manufacturers’ ability to quickly adjust and iterate during R&D and small-batch production.

Material cutting compatibility with different laser source.

| Material / Laser Type | Fiber Laser | MOPA Fiber Laser |

| Metal sheets | √ | √ |

| Metal foil | ○ | √ |

| Plastic | ○ | √ |

| Glass | – | √ |

| Ceramic | – | ○ |

| Silicone | – | √ |

| Gemstone | – | ○ |

Tips:

√ means the laser type is ideal for cutting this type of material;

○ means the laser type is able to cut this type of material, but there are some limits;

– means the laser type is not recommended for the job.

Clients who chose our handheld pneumatic dot peen marking machines

Want an un art handing video demonstration on specialized material? Looking for solution of your specialized environment or automatic process demanding?