Laser Marking Automation: A Comprehensive Analysis and Solution Selection

As markets become more cut-throat and customers expect goods tailored just for them, old-school hand marking simply cant keep pace with high-volume, speedy production. Enter automated laser markers, machines that load, line up, etch, and unload material all on their own, slashing labor bills and boosting efficiency.

In the pieces that follows, we step into the world of laser marking automation, breaking down how it works, what it can do for you, where people already use it, and the different system options on the table so you can design the ideal set-up for your operation.

What is Laser Marking Automation?

Laser marking automation weaves clever machines into the marking line, so people dont have to step in at every stage. It covers key chores like loading and unloading parts, centering them exactly, etching the mark, and checking if each piece is right. The work cell usually packs a smart controller, robotic arms, sensors, and cameras that talk to each other for smooth, fast action. Because of that, the setup shines in high-volume, repeat jobs found in electronics, cars, medical gear, and several other sectors.

Working Principle of Automated Laser Marking Systems

System Composition:

The automatic laser marking machine is composed of multiple interrelated and seamlessly collaborating components:

- Laser Source: This generator produces the focused beam that creates the mark. Common choices-fiber, CO2, and UV-lasers fit different substrates.

- Control System: The units software directs beam settings, coordinates the motion platform, and supervises all peripheral devices.

- Motion Platform: A set of motors and guides moves either the workpiece or the marking head with micron-level accuracy.

- Robotic Arm (Optional): The intelligent robot is responsible for loading and unloading parts and can make more precise marks on complex product surfaces.

- Sensors: Photoelectric or sensing devices are used to confirm whether each part exists, is oriented correctly, and is located in the correct area.

- Vision System (Optional): The camera records each mark, and the image analysis program marks defects or compares features with stored templates.

- Loading/Unloading Mechanism (Optional): This belt, chute, or pick-and-place device feeds raw work and evacuates completed pieces without human touch.

Workflow:

The automated laser marking procedure generally unfolds in the sequence that follows:

Part Preparation: Workpieces travel onto a belt, into a tray, or settle in any other suitable staging zone.

Automated Loading: A robotic arm or similar device takes a part and transfers it to the marking workstation.

Precise Positioning: Integrated sensors-or sometimes a camera-system pinpoints the item, guaranteeing the mark hits the right spot.

Laser Marking Execution: The control system triggers the laser to mark the workpiece according to pre-programmed parameters.

Quality Inspection (Optional): A vision system or sensor verifies the marking quality, checking for accuracy and legibility.

Automated Unloading: Finally, the robot or unloading system lifts the finished piece and sets it safely in the next designated area.

What are the Advantages of Automated Laser Marking Systems?

Bringing automation into laser marking brings several clear gains:

- Better production efficiency. Automated laser markers run full-speed for long stretches, cut down manual setup, and trim cycle times and costs, so output keeps moving.

- Greater accuracy. Robots can command every dot, line, and burn depth exactly, sparing the errors that slip in with human hands and lifting overall quality.

- Strong traceability. Each part gets a digital log that notes when, where, and by whom it was marked, making recalls and audits far simpler.

- Lower labor costs. The systems are easy to run, need only a few trained techs for upkeep, and that cut in staff translates to real savings.

- Higher safety. The machines monitor themselves and shut down on trouble, while less hands-on time near the beam protects workers from common hazards.

Applications of Automated Laser Marking

The applications of automated laser marking are vast and span across diverse indust:

- Electronics: Resistors, capacitors, and semiconductor chips are laser-coded with precision by computer-controlled laser markers, creating hard, legible codes.

- Machining: Same devices code metal or plastic parts, holding model numbers, sizes, batch codes, and other vital data.

- Medical: In medicine, lasers mark operating equipment, implants, and packaging so that each piece contains vital identification data.

- Food: In food processing, lasers code packages with date of manufacture, shelf-life indicators, and lot references to allow traceability.

- Automotive: Lasers also mark engine parts, body parts, instrument panels, and lighting components, helping manufacturers to mate pieces to quality controls.

Four Types of Automated Laser Marking Solutions

Automated laser marking solutions are designed to improve the speed, accuracy, and efficiency of laser marking processes. Here are four common types of automated laser marking solutions:

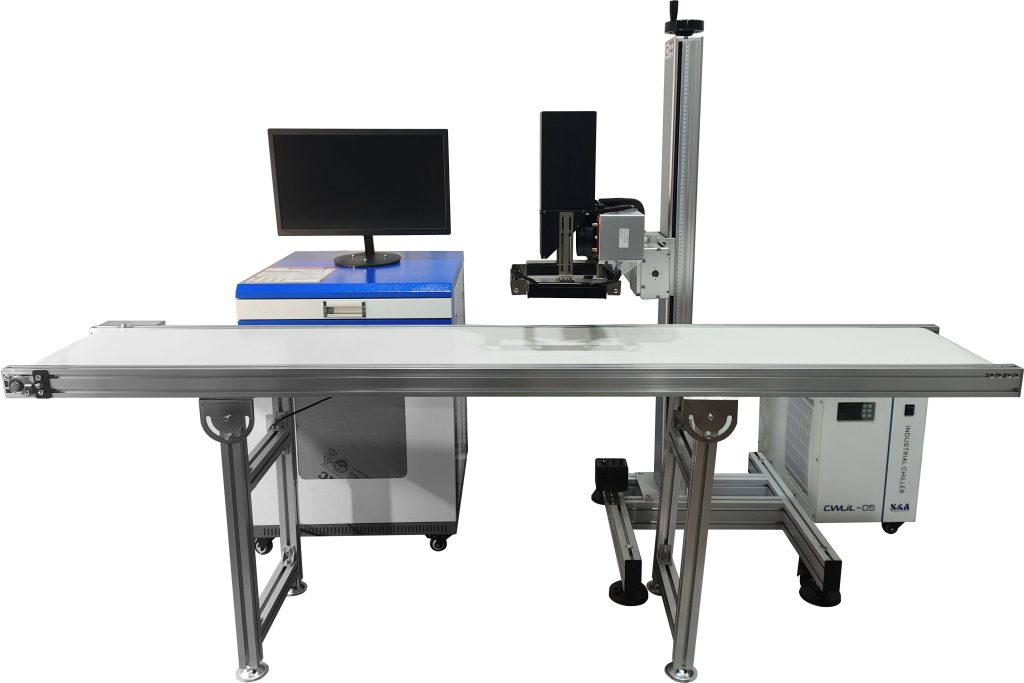

Online Solutions

Online solutions integrate the laser marking machine directly into the production line. This allows for seamless marking of parts as they move along the conveyor or production flow.

Advantages:

High throughput and fast marking speeds.

Ideal for high-volume, continuous production.

Reduced manual handling and labor costs.

Considerations:

Requires careful integration with the existing production line.

May require custom design and engineering.

Less flexible for handling different part types or marking requirements.

CCD Solutions

CCD (Charge-Coupled Device) solutions use cameras and vision systems to precisely locate and identify parts before marking. The CCD camera captures an image of the part, and the vision system analyzes the image to determine the exact position and orientation of the part. The laser marking machine then uses this information to accurately place the mark.

Advantages:

High marking accuracy and repeatability.

Suitable for applications with tight tolerances or complex marking patterns.

Can handle variations in part placement or orientation.

Considerations:

Vision system setup and programming may require expertise.

Cycle times may be slightly longer compared to online solutions.

Higher initial investment due to the vision system.

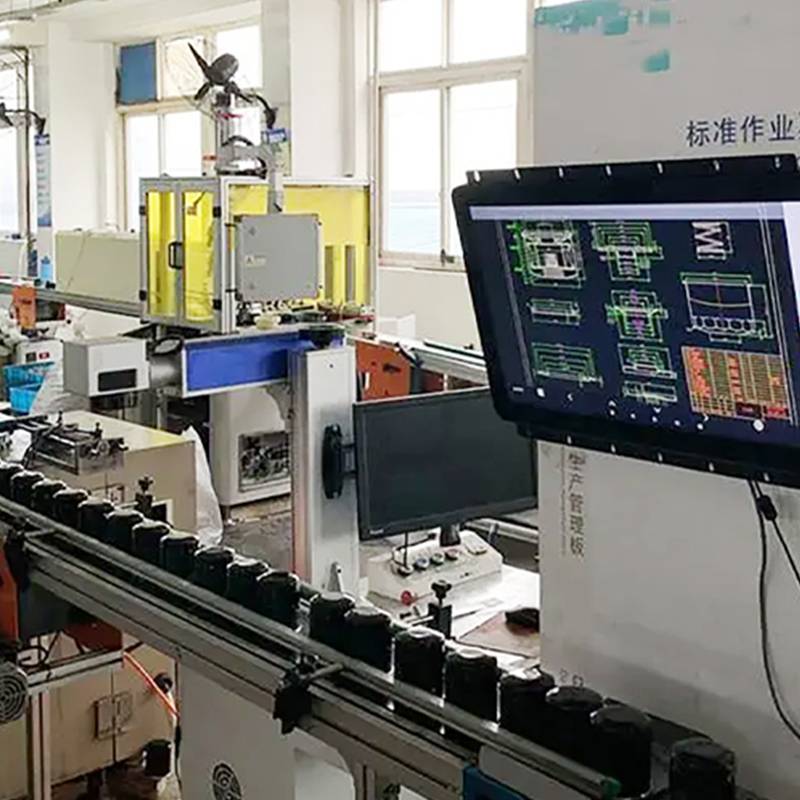

Flying Solutions

Flying solutions involve marking on parts that are in continuous motion. The laser beam is directed onto the moving workpiece, and the marking is performed “on-the-fly.”

Advantages:

Extremely high marking speeds.

Ideal for high-throughput applications with continuous flow.

Eliminates the need for precise part stopping and positioning.

Considerations:

Requires precise synchronization between the laser marking system and the moving parts.

Complex control and coordination.

May be limited in marking complexity or part types.

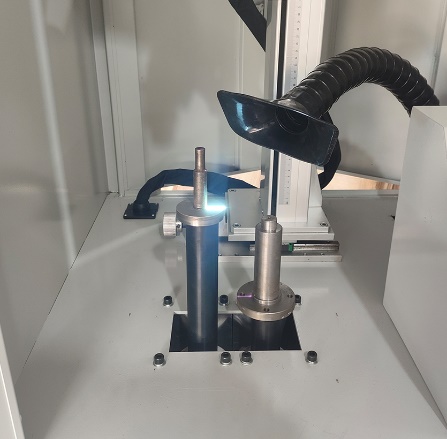

Multi-Axis Systems

Multi-axis systems use multiple axes of motion to achieve marking on complex 3D surfaces or curved parts. The laser head or workpiece is manipulated along multiple axes (e.g., X, Y, Z, rotation) to follow the contours of the part and create the desired mark.

Advantages:

Enables marking on complex shapes and surfaces.

High flexibility for various marking applications.

Can create intricate and detailed marks.

Considerations:

Requires advanced motion control and programming.

Higher system cost and complexity.

May have slower marking speeds compared to other solutions.

Choose Zixu to Start Building Your Automated Laser Solution

Zixu is a leading laser marking solution company, expert at designing and manufacturing high-quality automated laser marking machines. Based on years of experience and extensive understanding of laser technology, Zixu offers an entire range of solutions to fulfill diverse customer requirements. Our product range includes from single independent marking machines to integrated automation systems covering the latest advancements in laser technology, robots, and vision systems.

We are committed to providing:

- High-Performance Equipment: Our machines are built with robust components and cutting-edge technology to ensure reliable and consistent performance.

- Customized Solutions: We work closely with our clients to understand their specific requirements and develop tailored automated laser marking solutions.

- Comprehensive Support: We offer comprehensive after-sales support, including installation, training, and maintenance services.

Contact Zixu today to discuss your laser marking automation needs and let us help you build the perfect solution for your business. Our team of experts will guide you through the process, from initial consultation to system integration, ensuring a seamless and successful implementation.

Recommended Products