Accessories & Consumables

We manufacture rugged marking needles for our Dot Peen and Scribe marking machines, from basic 95 HRA tungsten steel, to titanium plated needle cores for increased durability, to diamond tips for extreme hardness. Even our competitors in the marking industry have recognized our technology and reliability and purchase from us. In recent years, we have produced and sold about 50,000 sets of marking needles per year, accounting for half of the entire Chinese market or 1/3 of the world market. We also provide a wide range of spare parts, software, and customize components of marking machines to meet the needs of each user.

Value:

our marking consumables and accessories provide the desired marking and marking effect at a reasonable price and for specific requirements;

Reliable:

all of our consumables and accessories are manufactured in-house or sourced from trusted industrial suppliers for total lifecycle reliability;

Flexible:

even after our equipment has passed its design life, customers can purchase spare parts to extend the life of their equipment at a reasonable cost;

Consistency:

Our marking consumables and accessories provide remarkable consistency after replacement without special tuning.

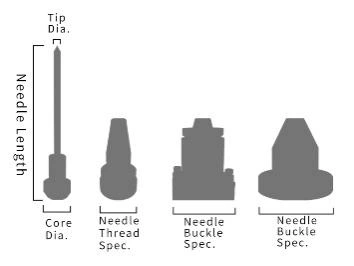

The marking needle is undoubtedly the most important consumable in a mechanical marking system, and its precision and durability are directly related to marking quality and economy. We manufacture a range of marking needles for pneumatic marking machines, electric dot matrix marker, and scribing machines. We offer multi-brand and multi-specification support.

Key Specification

| Used for | All Dot Peen Markers & Scribe Markers |

| Needle Length | Up to 300mm or customize |

| Tip Dia. | Up to 20mm caliber or customize |

| Needle Material | Diamond / Stainless Steel / Aluminum / Copper / More |

| Needle Mounting Spec. | Up to M45 screw / up to 40mm buckle or customize |

Sturdy and long-lasting needles for advanced use value

The best way to tell how good a marking needle is is to look at its hardness and how long it has been in use. All of our marking needle cores are cut from a single block of high-specification tungsten steel with a hardness of 93 HRA and even have diamonds incrusted on the tips for added hardness. The high hardness and sharp tip help produce crisp, sharp marking results on all common metal substrates.

Take care of the efficiency of production, not the price only

Our marking needles can last for more than 1000 hours of operation with proper marker configuration, and maintain a consistent marking effect throughout their life cycle. In addition, all our marking needles have high production consistency with tolerance ±0.01mm and no visible marking effect difference after replacing a new needle. In fact, many of our users choose our marking systems because they have experienced our needles on other brands of machines.

Low cost for easy replacement of the marking needle.

Our marking needles are inexpensive and durable, costing only a few hundred dollars for a full year’s use, making the cost of a complete marking system even less than a theoretical power-only laser marker. In addition, if the user replaces the needle cores in time to prevent shell wear, the cost of the needle cores alone will be even lower. Our needles are also easy to install and rarely cause injury.

Unbeatable value and reliability in the metal marking industry.

For more than a decade, we have been developing and iterating our pneumatic markers to improve reliability and marking performance. Today, our products have an excellent balance of initial purchase price, cost of ownership, and marking efficiency, and have been proven and accepted by many customers for a long time.

Mechanical moving parts worn out or damaged due to unforeseen circumstances? Have a new part specification that needs to be compatible? Want to integrate existing offline equipment into your Manufacturing Execution System (MES) for online operation? Relax, we offer most of our parts individually for you to select and purchase. Please select the parts you need from the different sections below.

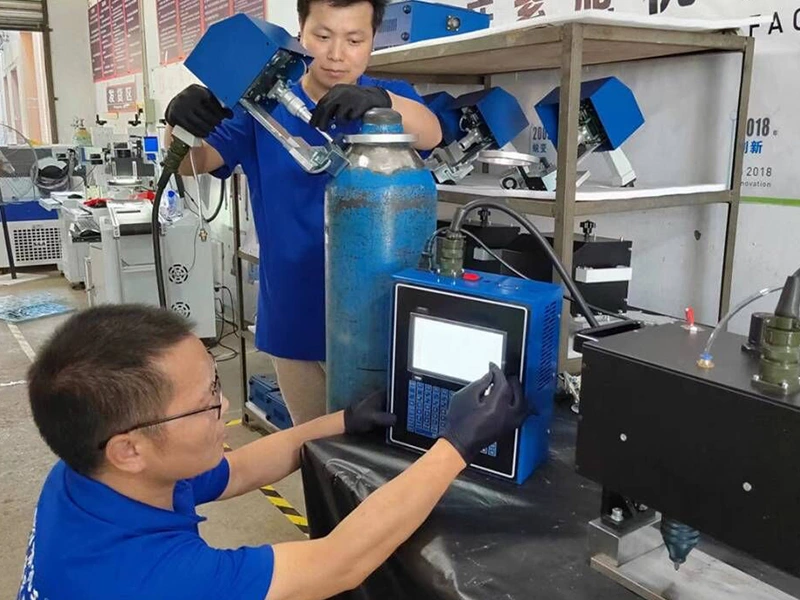

Controller

We offer four industry-proven basic control solutions that cover everything from the most basic offline marking tasks to inline marking with MES connectivity, and for each of the four control solutions we offer a range of options from complete controllers to individual control boards. You can view the specifications on our Controllers page to select the one you need. Whether you are looking to replace a damaged controller or upgrade a control module, we offer a complete and adaptable service or you can contact us directly for advice.

Accessories

We understand that the market and user needs are always changing and that your marking components may need to be replaced or modified in some way. Whether it’s a broken touch screen, a longer cable, a compact and reliable air compressor, a custom rotary mechanism, tooling, conveyor belts, or a worn limiter, needle holder, or even a motor for your marking machine, we have a long history of providing courteous service and quality replacement parts to extend the life of your markers and keep your marking process productive.